With the demand for high-precision platinum temperature sensors growing all the time, IST AG has decided to launch a new RTD PW series for high-precision measurements. This chip allows measurements in class F0.15 up to +600 °C with very low hysteresis due to its new 4-wire design.

Platinum Temperature Sensors

Platinum temperature sensors are prized for their high long-term stability and high robustness, e.g. with vibrations. As well as this, they emit an output signal that relates to the absolute temperature, making them especially useful for reference purposes, and giving them an advantage over thermocouples.

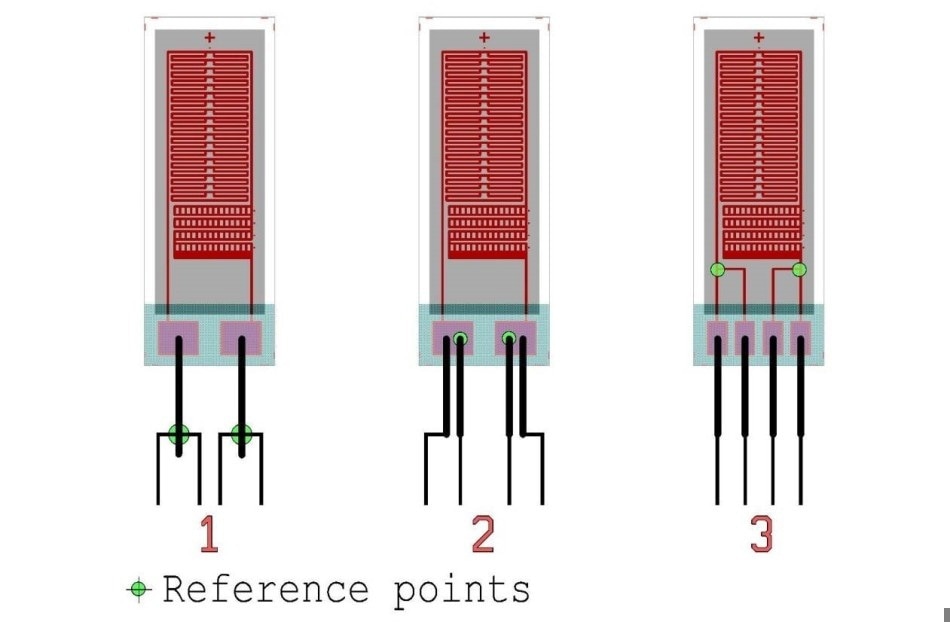

4-wire constructions have proven to be particularly good for high-precision temperature measurements, as they can effectively suppress wire resistances and their temperature influences. The reference point can also be placed in a number of locations. In the case of two-wire sensors, the four-lead extension is usually positioned at the wire end – the reference point is found at the extension point (see number 1 the in image below). This design can often lead to measurement inaccuracies, sometimes caused by minor alterations in position or thermal stresses from using different wire materials.

An additional problem arises when the extensions are attached directly to the welding pads using alternative means: if the welding points (glob-top) are covered in favor of strain relief, mechanical tension can result, and the installation of the sensor can result in drifts (see number 2 in the image below).

Upgraded Solution

Innovative Sensor Technology IST AG has studied and dealt with this problem intensively and has developed a new sensor which is specially designed for the needs of high-precision and long-term stable measurements.

The new 4-wire RTD has the reference points inside the sensor chip (see number 3 in the image below). The splitting onto four extended wires already happens in the meander area and outside the glob-top. As in the entire other meandering area, high-purity thin-film platinum is used here.

Different reference points (green) of 4-lead wire temperature sensors

The platinum film suppresses the contact resistance in this area and reduces the influence of mechanical stress around or because of the glob-top to a minimum. Minimal material variation from the chip side is guaranteed through the continuation of the four extended wires with pure platinum wires, suppressing thermal stress and making it highly stable in the long-term.

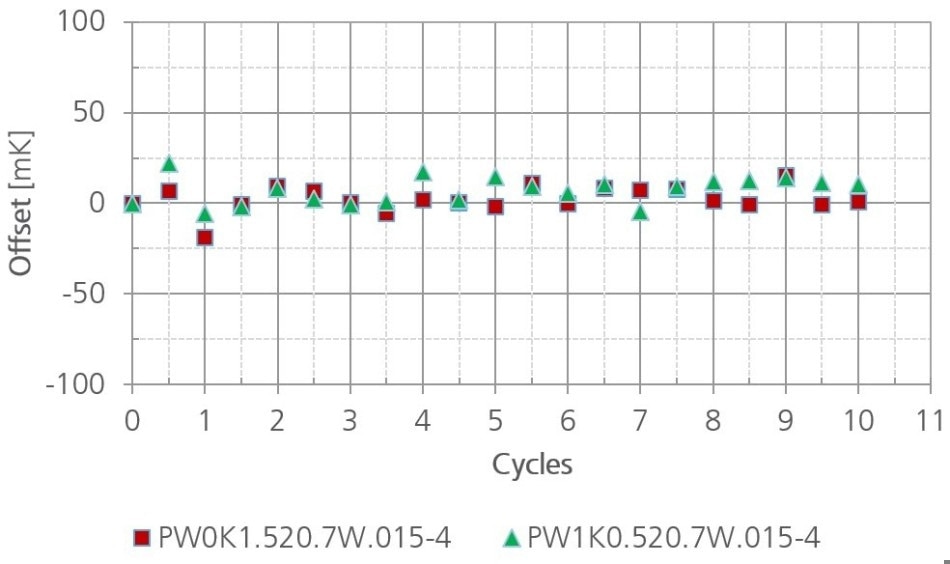

In using the previously established PW technology, the characteristics curve shows very good performance (according to IEC 60751) - the class F0.15 can be guaranteed in a temperature range of -200 °C to +600 °C. Additionally, the construction features reduced hysteresis, making the sensors suitable for measurements at very low temperatures as well.

Qualification samples of the 4-wire sensor are currently available (as of end of August 2018). For any inquiries please contact IST AG.

Hysteresis of 4-wire Pt100 and Pt1000 sensor

This information has been sourced, reviewed and adapted from materials provided by Innovative Sensor Technology - USA Division.

For more information on this source, please visit Innovative Sensor Technology - USA Division.