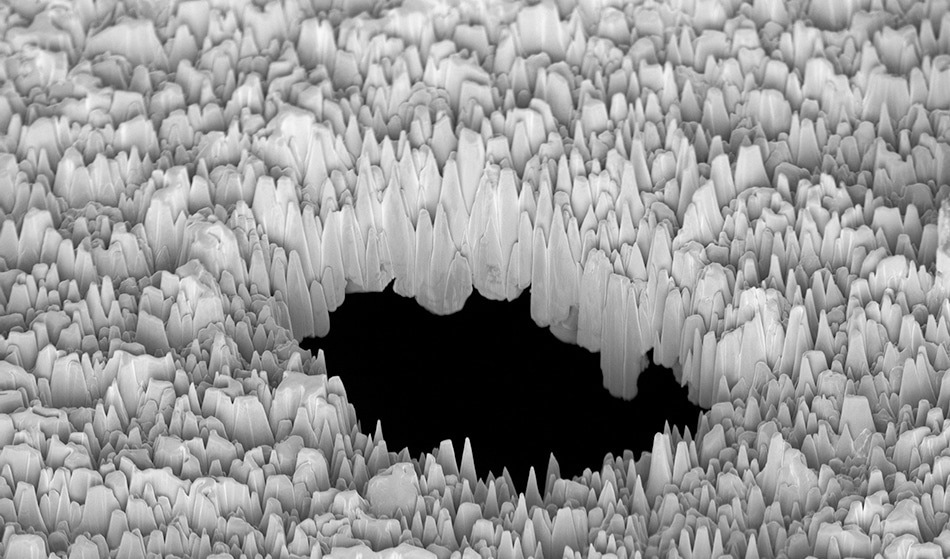

Image Credits: Roberto Lo Savio/shutterstock.com

Advancements in the development of laboratory microscopy instruments have provided researchers with improvements in the accuracy, resolution, and speed of imaging. To achieve these goals, various encoder sensors have been developed and tested for their usefulness when applied to electron microscopy (EM) systems.

The Role of Encoder Sensors in Microscopy

When analyzing samples under the microscope, it is common for researchers to require visualization of the entire sample. To achieve this, the microscope stage must be carefully moved without causing any mechanical errors that could affect the precision of their analysis.

Incorporating encoder sensors (including linear, incremental and absolute encoder sensors), into electron microscopy systems has been shown to increase precision, accuracy, and performance of imaging processes; all while requiring a minuscule amount of space within the microscope to achieve these objectives.

Linear Encoder Sensors and EM

Linear encoders, which have been considered as an ideal solution for position measurements, function by monitoring linear movement; providing information on the current position of a sample.

All information obtained by linear encoders regarding position measurement is in the form of electrical signals. Compared to optical encoders that require a light source and a photodetector to determine a sample’s position, light encoders are capable of eliminating the need for any intermediate mechanical elements that could interfere with the final image. Most precision linear encoders utilize a contact-free method of position tracking, either through optical or photoelectric scanning, to generate highly accurate measurements.

Incremental and Absolute Sensors

An incremental encoder sensor, which can be either linear or rotary, is equipped with two output signals that release pulses when the microscope stage is in motion. By reporting incremental changes in the sample’s position, all encoder signals acquired by the incremental surface are recorded and eventually compiled to provide information on the absolute position of the sample of interest.

Incremental sensors do not report a sample’s position until a reference point is established, whereas absolute sensors will unambiguously report a sample’s position without the need of any reference information, as long as its position falls within the designated scale or range.

While useful in practice, absolute sensors are often considerably more expensive compared to incremental sensors; thereby leading consumers to purchase approximately three times as many incremental sensors over absolute sensors. However, advancements in absolute sensing techniques have increased interest in using these types of sensors, since this new generation of inductive devices has been shown to exhibit greater accuracy while remaining unaffected by harsh environments.

Sources and Further Reading

- “Encoder Sensors for Microscopy – Automated Microscope Stages and Scanning Electron Microscopes”

- “Linear Encoder Options” – Applied Scientific Instrumentation

- “Gaining a measurement edge with linear encoders” – Linear Motion Tips

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.