In the majority of laboratory viscometers, the well-known principle of rotational viscometers is used for measuring the viscosity by sensing the torque needed for rotating a spindle at a constant speed upon immersing it in the sample fluid.

This is because the torque that is usually measured with the reaction torque on the motor is proportional to the viscous drag on the immersed spindle and therefore the viscosity of the fluid.

Using Rotary Torque Equipment for Consistency Measurement

AEA Technology intended to perform the consistency measurement of cement mixes for pressure injection into containers filled with radioactive waste since the injection of the mixture at the right consistency is important to ensure that it fills all the air spaces yet sets correctly.

AEA discovered that this could only be possible by using Rotary Torque Equipment from Sensor Technology and through exact measurement of the drive torque needed to rotate the mixer paddle at the time of mixing. After this work, several other applications involving the mixing of fluids with solids in suspension were similarly measured, for example, coal slurry, plaster mixes, and magnetic particles in fluid since it is extremely difficult to measure the viscosity of these mixtures by usual techniques. Online monitoring is required in the majority of cases.

In several other applications, monitoring the viscosity of the fluid during mixing is essential, for instance, while manufacturing pharmaceutical solutions and shampoos. Moreover, in such applications, it is important to identify the relative viscosity during mixing to determine whether the consistency or viscosity is at optimum and when the process is completed.

Operation

Given that the motor speed is constant, the torque will differ with variations in viscosity at the time of mixing, and thus the operator is allowed to determine the relative viscosity of the mixture. The size and type of the paddle control the relationship between the absolute viscosity and the torque, where the paddle will be designed to ensure mixing. Traditional viscosity measuring systems employ a cylinder instead of a paddle but certainly, a cylinder is not effective for mixing; therefore, absolute viscosity cannot generally be measured at the time of the mixing process.

It is possible to relate the relative reading to the absolute viscosity by measuring a known relative sample using a laboratory viscometer to acquire its absolute reading, thereby enabling the optimum relative torque figure to be identified, which signifies the viscosity that is needed.

Installation

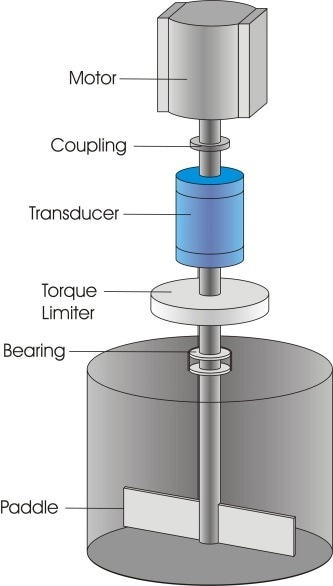

The Rotary Torque Transducer is set up between the paddle and the motor. Care must be taken not to connect the paddle directly with the transducer since the rotary transducers can be sensitive to side loads. This can be ensured by using double bearings to avoid any side loads.

A number of mixers are operated by motors that are several times powerful than what is required, and therefore, if the paddle mechanism is stopped, it can lead to severe overstrain or breakage of the inline torque transducer. Care must be exercised to protect the transducer using torque-limiting couplings.

This information has been sourced, reviewed and adapted from materials provided by Sensor Technology.

For more information on this source, please visit Sensor Technology.