Devices or designs embedded with FlexiForce™ sensors make use of the force sensor to correlate voltage output to an absolute unit of force (e.g., kilogram, newton, pound, etc.). This is regarded as an Absolute Measurement Application. Applications such as these follow a typical calibration procedure.

However, with regards to Relative Measurement Applications, this is considered when a force sensor is employed to correlate change in voltage to a change in force. So, force-sensing applications that fall under this category take a different calibration procedure.

Customer Story: Accounting for Drift in a Fluid Level Detection Application

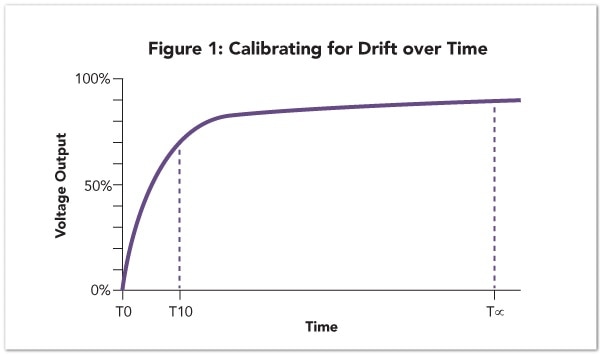

When the sensor is powered with the recommended circuit, as per Tekscan’s specifications, FlexiForce™ sensors tend to have an output drift rate <5% / logarithmic time. This means that the design engineer can expect that the absolute measurement may vary over time.

Therefore, instead of looking at a specific absolute voltage output, with relative measurement applications, the design engineer can correspond the change in voltage to the relative change of the force application. In simple terms, for relative measurement applications, the design engineer should check for the differential voltage output as a function of force (or, the slope of V vs F curve (Figure 1)).

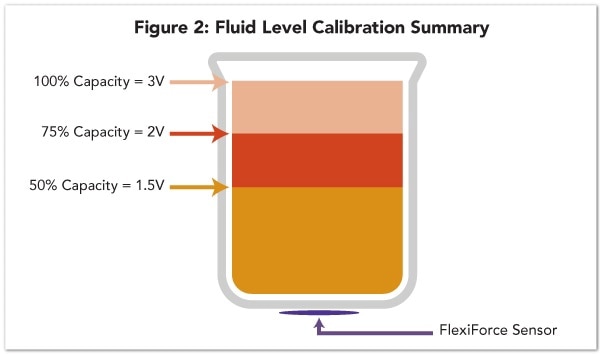

Here we have an example in which the customer’s requirement was to use a FlexiForce™ sensor as a method to ascertain the level of fluid within a container. For this application the sensor was positioned below the container, as shown in Figure 2.

Using absolute voltage outputs to measure fluid level within a container becomes a challenge because over time sensor drift is going to cause a gradual change in the sensor’s output voltage. For example, if the container remains half-full for a prolonged period of time, the static load would cause the output to increase under static load, and could determine an inaccurate level of fluid within the container.

Calibration Parameters for this Fluid Level Detection Application

| Container Level |

Circuit Output (V) |

Change in Output (V) |

| 100% |

3 V |

0 V |

| 75% |

2 V |

-1 V |

| 50% |

1.5 V |

-1.5 V |

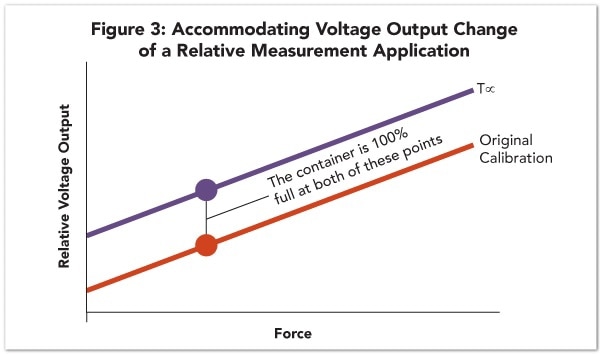

Therefore, a relative measurement is helpful in this application, because, contrary to absolute values, the slope of the V vs F curve remains relatively constant in spite of how much the output has changed (Figure 3). For that reason, the design engineer targeted a change in voltage (relative to 100% full) to indicate the fluid level in the container during this application.

As illustrated in Figure 3, the customer noticed that at 100% full, over time, the voltage output for the container increased from 3 V to a reading of 4 V. However, the design engineer can rest assured that even with a decrease in 1 volt because the differential voltage (with respect to force) remains the same, regardless of the absolute value, meaning the container fluid level has decreased by 25%.

Common Application Groups that Follow a Relative Measurement Approach

- Seal Integrity

- Contact detection

- Sensing differential pressure or force

- Inventory management

- Occupancy Detection

- Battery management

- On/off detection or switching

- Theft detection

- Presence detection

- Applications with routine temperature change

- Occlusion detection

- Triggering

- Thresholds

Using FlexiForce™ sensors to detect and measure relative change in force is just one of the four core applications this technology can be utilized in embedded applications. Register here for the free eBook that explains true tried and tested methods that can innovate your device using this design-friendly force-sensing technology.

This information has been sourced, reviewed and adapted from materials provided by Tekscan, Inc.

For more information on this source, please visit Tekscan, Inc.