Whether trying to consider if your force-sensing application will endure more than a million actuations or undergo just a few touches over its service life, validating the durability of a sensor is an expensive and lengthy process for OEMs.

The fundamental values of using force-sensitive resistor technologies in an embedded application (like FlexiForce™ touch sensors) are their flexible and thin form factors. Yet, there could be the assumption that due to the ultra-thin properties of this force sensor type it may not withstand the rigors of high-volume loading cycles.

Therefore, using the most extreme testing parameters to date, Tekscan put their sensors through a series of vigorous trials in order to help you make a better-informed decision on whether FlexiForce™ touch sensors will be right for your application.

Inside Tekscan’s technical whitepaper, “FlexiForce™ Sensor Durability, Drift, Recovery, and its Impact on Your Design”, they provide a summary of two sensor performance experiments conducted by inhouse applications engineers:

- FlexiForce™ sensor durability assessment following one million force actuations under extreme testing parameters, and

- FlexiForce™ sensor recovery evaluation following 10,000 actuations

Subsequently, once these experiments were completed, sensors were analyzed for linearity and any change in sensitivity.

Although results from the recovery and durability trials are not absolute across every single FlexiForce™ sensor that Tekscan manufacturers, this document is still representative of sensor longevity as an embedded component in a high force-actuation application.

Here’s a Sneak Preview into One of the Experiments:

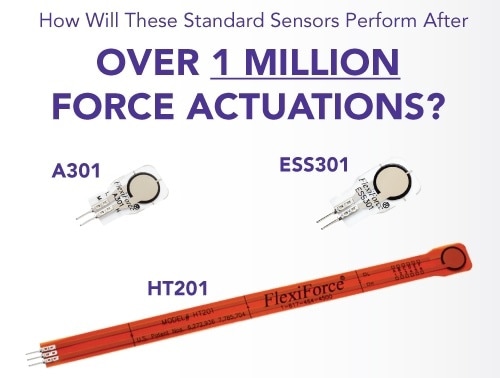

Summary: Using a pneumatic air cylinder testing fixture, a trio of FlexiForce™ standard sensor models (A301, ESS301, and HT201) were normally actuated with a 2.3 kg (5 lb) load over one million times. Each sensor was driven using a non-inverting op amp circuit (single source). The loading profile and schematic went as follows:

- Preconditioning of the sensors to 120% of the test load (2.7 kg (6 lb) for 20 seconds, twice)

- 5 up step profile to 2.3 kg (5 lb) implementing a 10-second dwell at each step

- 2.3 kg (5 lb) load applied at 1 Hz, 50% duty cycle for 100,000 actuations

- 5 up step profile to 2.3 (5 lb) implementing a 10-second dwell at each step

- 5-minute rest with no load

- 5 up step profile to 2.3 (5 lb) implementing a 10-second dwell at each step

- Repetition of steps 3-7 until one million total actuations were achieved

Once the experiments were completed, the three sensors were carefully examined against Tekscan’s published performance expectations for linearity error (< ±3% of Full Scale (Line drawn from 0 to 50% load)) and any transformations in sensitivity.

Would you like to know more? Click Here to Download the Whitepaper Now!

This information has been sourced, reviewed and adapted from materials provided by Tekscan, Inc.

For more information on this source, please visit Tekscan, Inc.