Article Updated on 16 March 2021

Image Credit: Igor Podgorny/Shutterstock.com

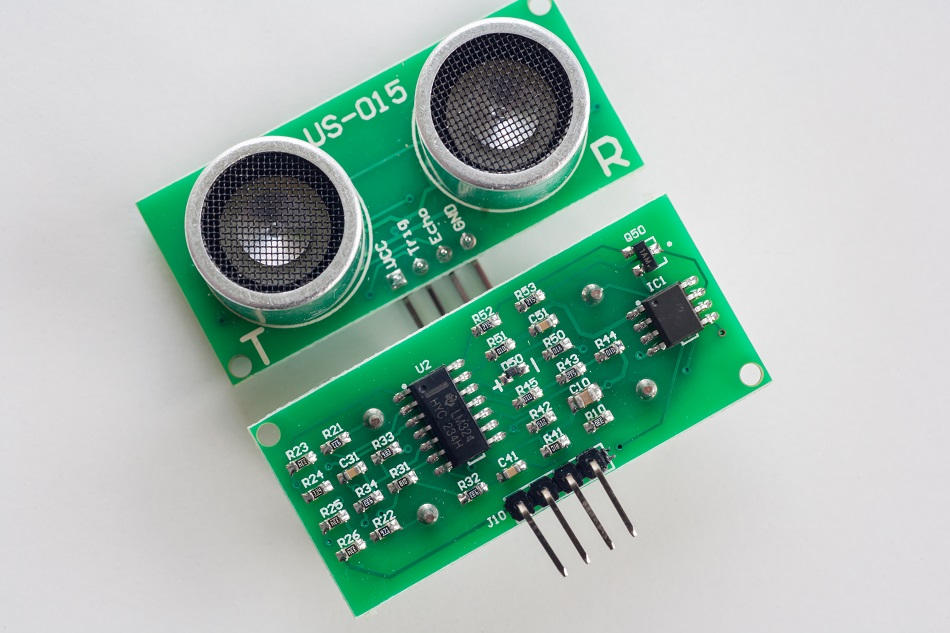

Ultrasound sensors are highly sensitive and accurate systems capable of detecting and monitoring objects located at varying distances from the sensor system. More recently, this reliable sensor technology has been used to assist in gas flow measurement procedures.

Introduction to Ultrasound Sensors

As the name indicates, ultrasound sensors, which are otherwise referred to as ultrasonic sensors, obtain distance measurements through the use of ultrasonic waves. More specifically, the head of an ultrasound sensor will emit an ultrasonic wave, which will eventually be reflected off of the target and back to the sensor’s head. The time between the emission of the ultrasonic wave and its subsequent reception is used to determine the distance between the sensor and a target object.

Types of Ultrasound Sensors

Ultrasound sensors can be divided into two subtypes, which include proximity detection sensors and ranging measurement sensors. When an object passes through a preset range, proximity detection ultrasound sensors will detect the moving object and generate an output signal that reflects its location in reference to that of the sensor. Ranging measurement ultrasound sensors will instead measure both the transmitted and reflected ultrasound waves when an object is continuously moving.

Applications of Ultrasound Sensors

Ultrasound sensors can be found in a wide variety of applications within the automotive, robotics industries, as well as for weather monitoring purposes. Some of the most well-known applications of ultrasonic sensors can be found in unmanned aerial vehicles (UAVs), which are more commonly referred to as drones. UAVs often utilize ultrasonic sensors for the detection of any adjacent objects to prevent aircraft crashing, as well as for monitoring the position of specific targets of interest present on the ground below the drone.

Ultrasound Sensors for Gas Measurement

As sensor technology continues to advance, several companies have discovered ways in which ultrasonic sensors can be used to detect and measure gas flow for a wide variety of industrial purposes. Prior to these developments, sensor manufacturers were challenged with how the acoustic stability of their sensors could be optimized for ultrasonic gas metering purposes. Since gas flow mediums typically exhibit inherent turbidity and continuously changing property characteristics as a result of temperature fluctuations, sensor developers needed to create novel systems that minimized the occurrence of any measurement errors that could be attributed to these traditional challenges.

Ultrasound Sensors and Time of Flight (ToF)

In order to measure the volume flow of gas, ultrasound sensors can often measure the time of flight (ToF) of an ultrasonic wave. As the gas flows in both upstream and downstream directions, these ToF ultrasonic sensors calculate the difference in propagation time between ultrasonic signals. Typically, ultrasonic sensors will have a normal drive frequency within the range of 160 kHz up to 600 kHz. The advantage of using ultrasonic sensing transducers with a higher frequency is that the waves in this category attenuate more quickly, thereby making these sensors ideal for applications with space constraints, such as within a small pipe.

Sources and Further Reading

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.