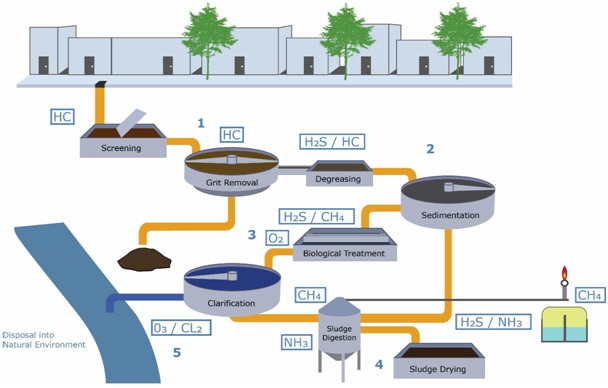

Both wastewater and drinking water treatment facilities generate and utilize a variety of toxic and explosive gases. These include methane, hydrogen, chlorine, ozone, sulfide, ammonia, carbon dioxide, and carbon monoxide.

In confined spaces, the increased concentration of these toxic gases coupled with the decreased amounts of available oxygen makes these areas especially hazardous for workers and contractors.

A range of different technologies can be used to detect gases that may be present in water treatment facilities. These are outlined below.

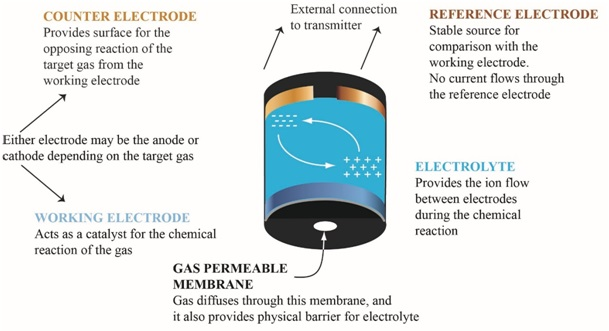

Electrochemical Sensors

Electrochemical sensors can be used to monitor oxygen levels in the air, or to detect the presence of toxic gases like H2S, and, CO Cl2.

An electrochemical sensor utilizes an aqueous electrolyte solution to provide a conductive path, allowing ions to travel between electrodes. Target gases will be either oxidized or reduced at the working electrode, thus resulting in current flowing between the working electrode and the counter electrode.

A reference electrode gives a zero reference point, and from this, the resulting difference in potential between the working and counter electrodes can be measured and compared. This allows target gas levels to be calculated in parts per million (ppm).

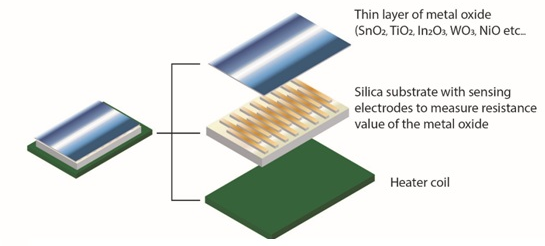

Semi-conductor Sensors

Semi-conductor sensors are often utilized where there may be high concentrations of H2S or in environments with a high ambient temperature.

Metal oxide semiconductor gas sensors use thin films of metal oxides which are placed upon a silica substrate. The substrate is then heated to around 200-600 °C while the metal oxide’s resistance is continuously monitored.

The sensor will respond to changes in the atmosphere because the resistance value of the metal oxide will change when it is exposed to target gases.

Catalytic and Infrared Sensors

Catalytic sensors are primarily utilized in the detection of potentially explosive gases. Meanwhile, infrared sensors also tend to be used for the detection of specific explosive gases, for example, carbon dioxide (CO2) or CH4.

It is advisable to use infrared technology sensors in environments where corrosive atmospheres are present, or where there are high levels of H2S. A continually high concentration of H2S (higher than 3 ppm) will likely result in saturation and poisoning of standard catalytic cells.

In moist, saline, or corrosive environments or where a high concentration of H2S is present, stainless steel (INOX) detector housings are recommended to ensure maximum longevity. A sampling enclosure is recommended for use in confined spaces.

Biological treatment facilities are usually located a long way away from production facilities, with staff who maintain and work these facilities often lone working. In order to ensure their complete safety, operators are outfitted with portable gas detectors, which are tested and maintained regularly.

Teledyne Gas & Flame Detection’s infrared sensor cells are not sensitive to ‘poisons’ such as and H2S and chlorinated solvents. Not only does this mean that they last longer and are guaranteed for five years, but routine maintenance only involves one test every year. Infrared sensors’ energy consumption is also two times less than that of catalytic detectors.

Teledyne Gas & Flame Detection Can Provide a Diverse Array of Portable and Fixed Detectors

The company’s industrial product line was designed for use in the most extreme and hazardous environments. It is well suited for use in the water sector, as well as for use in areas both with and without explosion hazard classifications, high protection index, polyester or stainless steel casing.

Teledyne Gas & Flame Detection’s units offer various functional features, such as TCP/IP interfaces, RS-485 outputs, backlit LCD displays, programmable relays, and 24/7 data recording. Wireless solutions are also available.

This information has been sourced, reviewed and adapted from materials provided by Teledyne Gas and Flame Detection.

For more information on this source, please visit Teledyne Gas and Flame Detection.