Reliable Leakage Monitoring in Hallertau, Germany

Hops that come from the world-famous Hallertau hop-growing region are a must when producing Germans' favorite drink – beer. Hops are one of the four ingredients permitted by the German Purity Law for brewing beer together with barley malt, yeast and water.

Hops preserve and season the beer naturally, and the hop refinement process standardizes the bitterness of the hops to ensure that there are no fluctuations in the quality of the beer.

The hops also retain their full, naturally fresh aroma and keep for longer. From 100 kg of raw hops, around 45 kg of hop pellets can be created. Hop refinement allows better storage and freshness and also makes transport a lot easier.

Image Credit: MSR-Electronic GmbH

Refinement happens after the hops harvest. The hop cone is freed from heavy material and metal during this process. A cutting mill is used to pulverize the purified mass and it is homogenized again in mixers with a capacity of around 3 tons. It is then dried in hordes.

The powder finally reaches the pellet press where, with the help of rollers and matrices, it is processed into hop pellets and dried again. During the drying process, CO2 is added, which is subject to permanent monitoring. This is attained by utilizing CO2 gas sensors from MSR-Electronic.

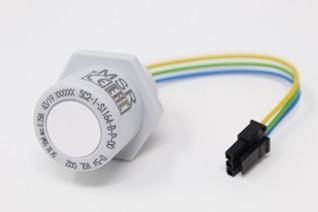

The exchangeable sensor (type SC2 and type MC2) with temperature compensation, digitized measured value processing, and self-monitoring for continuous monitoring of the ambient air for gases and vapors can protect people and plants.

Further to the measuring amplifier and sensor element with infrared sensing technology, for the processing of measured values, the sensors also contain a μController. Despite long calibration intervals, the IR measuring principle ensures the highest selectivity, accuracy, and reliability.

In a fail-safe way, all data and measured values of the sensor element are stored in the μController and are digitally transmitted via the local bus to the sensor board SB2 or MSB2. The μController of the sensor also has integrated calibration management.

Image Credit: MSR-Electronic GmbH

Calibration is performed either by simply replacing the sensor cartridge or by utilizing the comfortable, integrated calibration routine directly at the system.

In the drying process of hop refinement, the DGC-06 Digital Gas Controller from MSR-Electronic is the central unit for complete gas monitoring. It is a measuring, warning and controlling device system for toxic and combustible gases.

The DGC-06 Digital Gas Controller was developed for large systems or even for extensive connections. Everything is possible, from access functions that are switched by gas alarm to large-capacity laboratories, breweries and complex garages.

The DGC-06 gas controller series can monitor and evaluate up to 128 gas sensors, 96 of which are digital and/or 32 analog sensors (4–20 mA) and is designed according to EN 50545-1. Each sensor has four freely adjustable alarm thresholds.

The controller system has up to 128 relays for alarm messages. These have potential-free change-over contact and up to 16 analog outputs with 4–20 mA signal.

Information on further MSR products can be found here in the current online catalog or in the web shop: www.msr-24.com.

MSR-Electronic is a manufacturer of fixed gas warning systems. It has decades of experience building automation and gas measurement technology. With headquarters in Germany, the international company has a large range of techniques for the detection of combustible and toxic gases.

On this basis, MSR-Electronic develops individual controllers, gas sensors, and warning devices for numerous applications, such as tunnels, parking garages, and petrochemical industry or shipping. The products can guarantee the safety of the plant as they meet more than the general standards and regulations.

This information has been sourced, reviewed and adapted from materials provided by MSR-Electronic GmbH.

For more information on this source, please visit MSR-Electronic GmbH.