This article outlines the benefits of using RFID tags for asset management or in hazardous process industry settings when balanced against conventional barcode solutions.

Image Credit: Extronics Ltd

Uses of RFID Tags and Barcodes in Hazardous Areas

In hazardous areas, radio signals can be a potential cause of explosions. Therefore, the use of Radio Frequency Identification (RFID) needs to be taken into account with careful consideration. Adaptable and cost effective, passive RFID systems can boost efficiency, limit downtime, and increase productivity.

These systems have shown their worth to industrial companies, assisting with the tracking of assets and personnel, maintenance planning, inventory management, and much more. Thus, the use of RFID systems is becoming increasingly common and widespread in various hazardous areas.

The updated IEC 60079-14 standard reflects the recent rise in popularity. Moreover, in June 2014, a new clause with regards to RFID tags was added, which presents new implications concerning their use in hazardous areas.

Clause 5.15 stipulates that passive tags do not have to be certified if they meet the criteria for simple apparatus: all seems clear. Yet, most readers generate an electromagnetic field exceeding the RMS value limits set out in the aforementioned standard.

Therefore, the tags must be certified as safe by an approved body to read passive tags in hazardous areas. Raising awareness of this issue is a key concern as passive RFID technology becomes widely adopted, and as readers decrease in size, becoming handheld, and more mobile – there is a greater likelihood that they will appear and be used in hazardous areas.

RFID Tags Instead of Barcodes

An RFID tag, especially the state-of-the-art Ultra High Frequency (UHF) type, has multiple advantages over a barcode:

- The RFID reader does not need to be aimed directly at the tag, unlike a barcode scanner

Resultingly, an RFID tag can still be easily read in a place that is less accessible or on objects in an automated line where the position of the tag cannot be in the same alignment each time.

- Harsh and dirty environments can lead to a barcode becoming damaged, spotted, or smudged, making it difficult or impossible to read

Yet, an RFID tag can be totally obscured yet still be perfectly readable.

- What’s more, multiple RFID tags can be read simultaneously

For example, several items tagged on a pallet can be easily identified without searching for their individual bar codes, ensuring rapid processes are in place without a loss of accuracy.

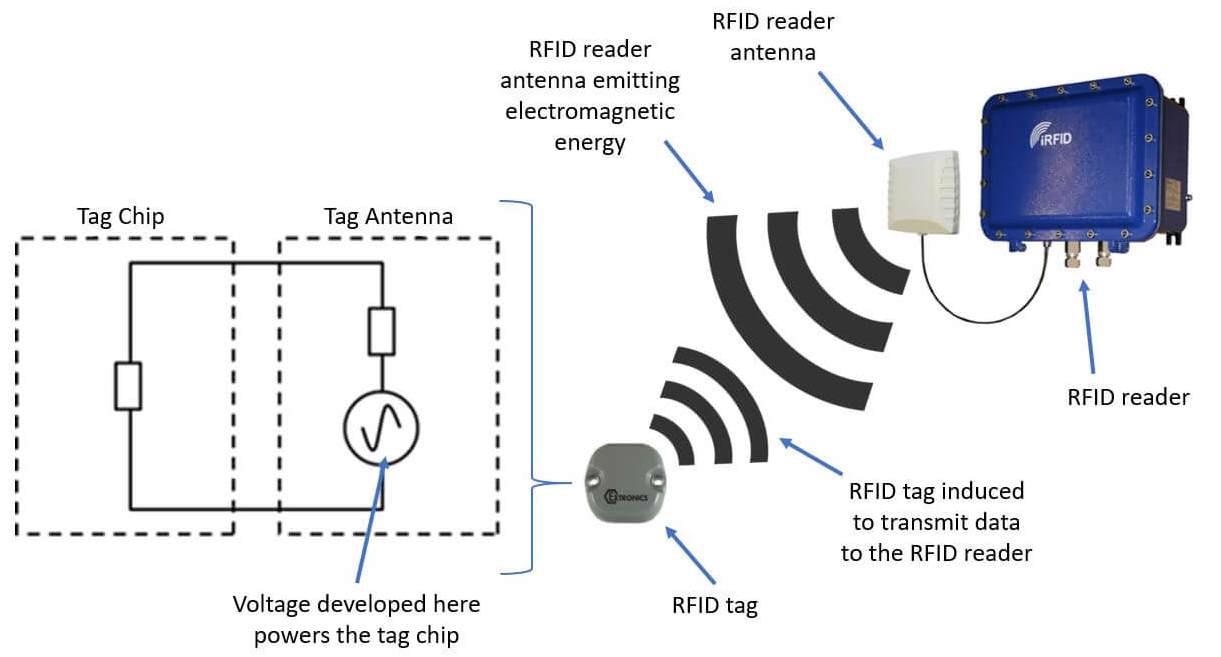

RFID tag and reader diagram. Image Credit: Extronics Ltd

Evolving RFID Technology

Over the years, various types of RFID technology have been utilized. The original tags were Low Frequency (LF), first employed in animal husbandry, but their initial slow read rate made them unsuitable for high-speed industrial applications.

Next came High Frequency (HF) tags, generally used in applications such as credit cards or passports, but their read range is short and not optimized for the process driven industries.

There are often legacy applications that utilize LF and HF tags, but the most-recent Ultra High Frequency (UHF) technology is typically considered to be most convenient for process industries and general manufacturing in the future. Their rapid read rate, extended range, and cost effectiveness make them the practical option.

Extronics RFID Solutions

Extronics is able to provide a wide range of inherently safe passive UHF RFID Tags and readers that are suited to any process industry application.

Extronics specializes in the development and manufacturing of ATEX, IECEx, and North American certified equipment for use in hazardous areas, as well as robust industrial products for tough, harsh environments. Serving customers all over the world, including oil and gas industries as well as the chemical, pharmaceutical, and mining industries.

This information has been sourced, reviewed and adapted from materials provided by Extronics Ltd.

For more information on this source, please visit Extronics Ltd.