In this interview, AZoSensors talks to Bruno Menard, Software Director at Teledyne Dalsa, about the increasing involvement of Artificial Intelligence in the manufacturing industry.

Please could you give a brief overview of Teledyne DALSA and the work you are involved in?

Teledyne DALSA is part of the Teledyne Imaging group and a world leader in the design, manufacture, and deployment of digital imaging components for the machine vision market.

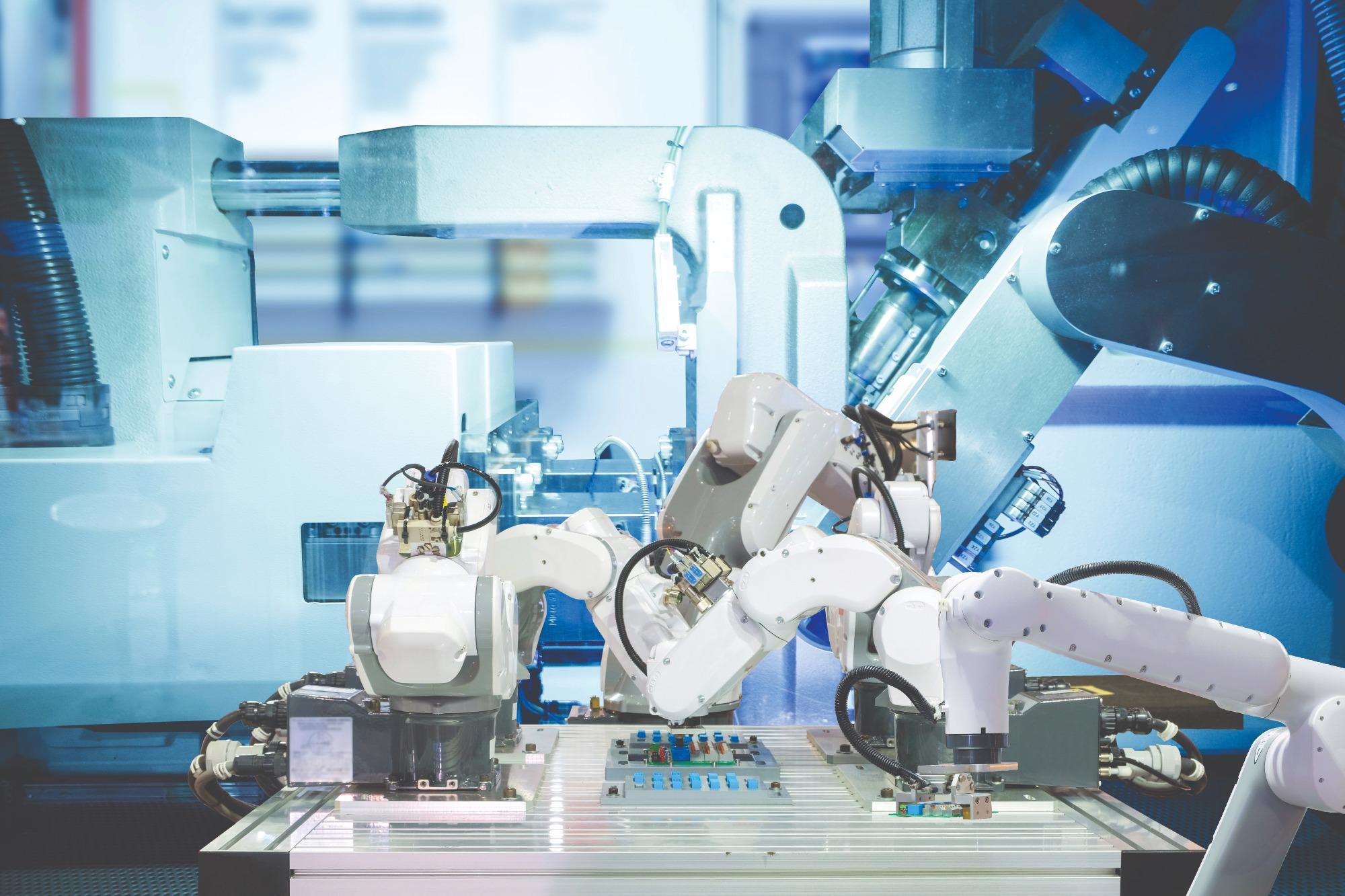

Teledyne DALSA image sensors, cameras, smart cameras, frame grabbers, software, and vision solutions are used in thousands of automated inspection systems around the world and across multiple industries including semiconductors, solar cells, flat panel displays, electronics, automotive, medical, packaging, and general manufacturing.

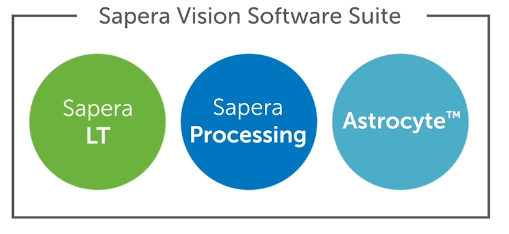

Since 2018 Teledyne DALSA’s AI Team has been working on the development of an AI training and deployment software suite. As part of the Sapera Software Suite, the Astrocyte training application is dedicated to solving challenging vision problems while being integrated into the set of vision components from Teledyne DALSA.

How would you say AI is changing the manufacturing industry?

With the advent of AI, the manufacturing industry has pushed the limits to a higher level by automating more and more steps of the inspection chain. AI-based software has become reliable enough to autonomously identify and quality defects on the inspection process bringing down the total system cost and improving the yield.

Compared to more traditional methods of inspection, what are the advantages of AI?

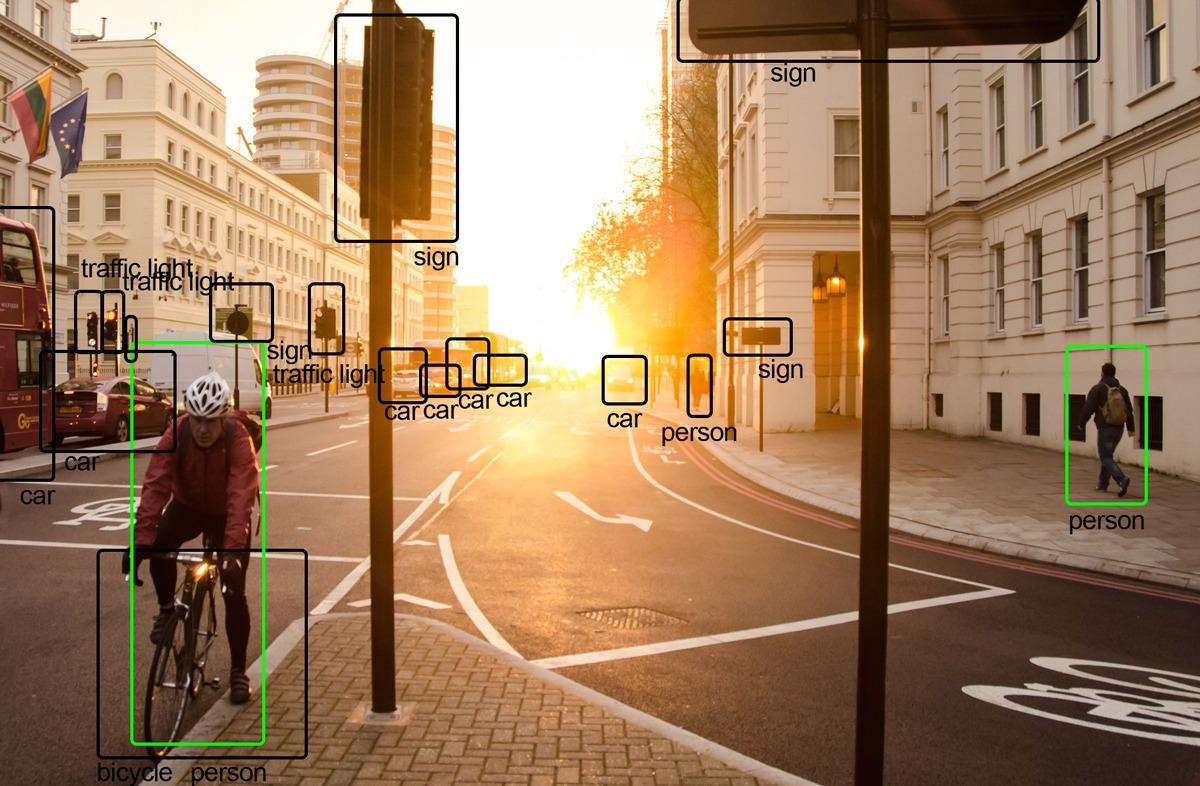

AI brings two major advantages. First, it allows solving problems involving significant variations in scene (objects and background) that were very difficult and even next to impossible using traditional rule-based vision.

Second, AI-based systems are easily adaptable to new variations by retraining the system with new samples as opposed to painful fine-tuning of thresholds in traditional algorithms.

What part is Teledyne playing in this AI revolution?

Teledyne DALSA offers a flexible set of tools, including AI training and deployment software, that are dedicated to different types of users. OEM manufacturers, System Integrators and End Users can all benefit from this toolset.

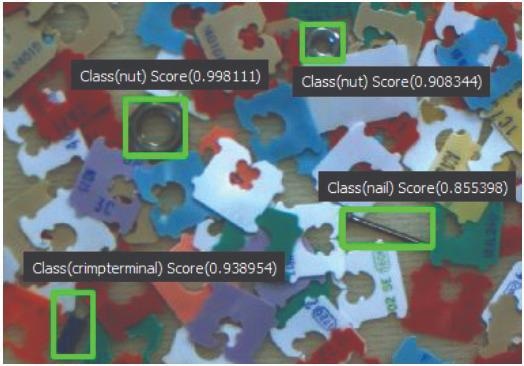

It pushes them a step forward in the integration of AI in their challenging applications such as detecting particles on a glass surface, locating flaws on an automotive part, or qualifying ripeness of fruits.

Teledyne DALSA’s products cover both image acquisition – via high bandwidth and resolution cameras of various wavelengths, and image processing – through a suite of flexible operators including basic processing, image analysis, and AI.

What key features make the Sapera software useful for industrial inspection?

The Sapera Software Suite includes the Astrocyte AI training application which shows the following key advantages: (1) it is a fully integrated Graphical User Interface permitting rapid application development in AI, (2) it trains and runs on the user system making it completely independent of the cloud and ensuring full data privacy, (3) it offers are sets of various AI architectures including classification, object detection, segmentation and others which act as the building blocks for building a dedicated AI model, (4) it trains on user-provided image samples to ensure high performance when deployed in the field, and (5) it comes with a set of visual model assessment tools to make training quick and easy.

Astrocyte is used at training time while Sapera is used at deployment time. Sapera provides a large series of functional primitives for image acquisition, device control, image processing, and AI inference.

How is Teledyne going to continue to be involved in the use of AI in manufacturing?

Teledyne DALSA will continue to focus on providing a variety of high-performance tools serving a wide range of customer needs. We are actively working on enlarging our support in terms of AI algorithms including semi-supervised learning, continual learning, and others.

We are committed to delivering to our customers, adaptable software that not only runs on PC but also on embedded platforms like smart cameras and industrial vision systems.

In terms of the future, how do you see the field evolving?

The AI world is in perpetual change and will continue to bring tangible solutions to the vision and manufacturing industry in the coming years. Among challenges are: (1) reduce the training effort via unsupervised learning, (2) create AI software that adapts itself to context change after being deployed in the field, and (3) provide more application-specific off-the-shelf solutions based on AI.

Where can readers find more information?

About the Researcher

Bruno Menard is Software Director at Teledyne DALSA. With over 25 years in Machine Vision software, Bruno has experience in image processing and analysis such as barcode reading, pattern matching, OCR, 2D/3D measurement, color analysis, and artificial intelligence. He has managed several projects including image processing deployment on various embedded platforms and processors. For the last 3-4 years his focus has been dedicated to innovation in 3D image analysis and artificial intelligence. Bruno holds a master’s degree in engineering from Ecole de Technologie Superieure, Montreal, Canada.

This information has been sourced, reviewed and adapted from materials provided by Teledyne DALSA.

For more information on this source, please visit Teledyne DALSA.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.