AZoSensors speaks with a team from the Center for Advanced Smart Sensors and Structures (CASSS) at Western Michigan University, led by Dr. Massood Atashbar. The team has developed a new specially designed pressure-sensitive cap that can help protect athletes from serious head injuries.

Can you give our readers a summary of the research carried out by your team at Western Michigan University?

Our team is a part of the Center for Advanced Smart Sensors and Structures (CASSS) at Western Michigan University. We are a group of researchers with an interdisciplinary background working under the guidance of Dr. Massood Atashbar, a Professor in the Electrical and Computer Engineering department.

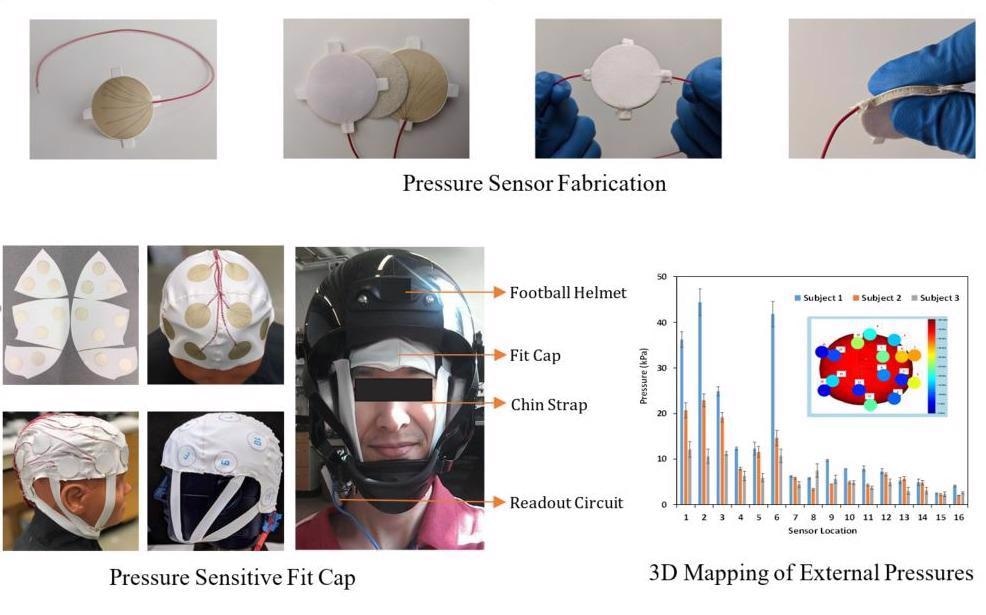

We are focused on the design and development of electronic devices based on a relatively new field called "flexible hybrid electronics (FHE)", which utilizes the best of the conventional MEMS-based technologies and printing processes. Our team has developed various cost-effective, thin, and flexible sensors and actuating systems, including those that monitor temperature, humidity, pressure, and strain. The team has also worked on smart wound bandages, microplasma-based sterilization, dry ECG electrodes, medical devices to monitor cardiopulmonary diseases, energy harvesters, microfluidics, and much more. We have been trying to use these sensors and devices to address the day-to-day problems people face and bring them to the market. In this process, to improve the safety of the teens and adults in sports, we used pressure sensors and successfully developed a pressure-sensitive cap.

The research team with the pressure-sensitive fit cap and helmet; (left to right) Masoud Panahi, Simin Masihi, Dr. Binu Narakathu, Dr. Massood Atashbar, Anthony Hanson and Dr. Dinesh Maddipatla.

What's the importance of ensuring protective headgear is fitted correctly?

Many athletes, such as football players, rely on headgear (helmets) to protect themselves from severe head injuries during the game. However, a proper fitting to the athlete's head is integral to the helmet's functionality and the performance of the athletes. In other words, athletes will still be vulnerable to traumatic brain injuries (TBI) if the helmet is not fitted correctly on their head. If not fitted correctly, helmets do not provide the necessary protection during falls and impacts in the field.

In 2017, Boston University conducted a study that showed 99% of NFL players tested suffered from CTE. How can this cap help in preventing chronic traumatic encephalopathy (CTE)?

According to the Center for Disease Control and Prevention (CDC), approximately 4 million concussions occur annually in the USA, of which more than 50% are unreported and therefore undiagnosed. In addition, most NFL players are prone to concussions which often lead to chronic traumatic encephalopathy (CTE) and TBIs, which are a major cause of death and disability in the USA.

Field data from helmet original equipment manufacturers (OEM) and players suggest that loose/improper fitting helmets contribute to CTE and TBI. The problem of proper helmet fit (helmet movement on the head during use) is also recognized by the OEMs as an essential aspect of performance and safety. However, helmet fit is currently not being addressed. Moreover, currently, there are no devices that can provide information on the proper fit of a helmet on a player's head. Monitoring the proper fit of the helmet on players' heads can significantly decrease the severity of brain injuries by increasing the maximum protection that the helmet can provide.

Can you explain how polydimethylsiloxane (PDMS) material is used as part of the porous capacitive sensors that are employed in the cap?

We developed capacitive sensors using polydimethylsiloxane (PDMS) material to detect the amount of externally applied pressure. We devised a facile technique for creating porous PDMS material through the thermal decomposition of sodium bicarbonate. The working mechanism of this pressure sensor resembles a parallel plate capacitor with a porous PDMS dielectric layer sandwiched between two fabric-based conductive electrodes. When the sensor gets exposed to external pressure, the porous PDMS is compressed between the electrodes causing a capacitance change. This porous PDMS material experiences large deformation, when compared to a solid/non-porous PDMS layer, and thus increases the capacitance change making our pressure sensors highly sensitive. The sensors made using the novel porous PDMS in our cap can reliably sense a wide range of the applied pressures that the players' head may sustain in the field.

How does the pressure-sensitive cap help protect from serious head injuries? What benefits could the pressure-sensitive cap bring to protective headgear that is used in sports?

Athletes have different head sizes and shapes. However, typically the helmets are available only in 4 sizes and come in a standard shape. There are no devices on the market that can provide information on the proper fit of the helmet on a player's head. Our novel pressure-sensitive fit cap is flexible, conformal to the head, has real-time 3D pressure mapping capability, and provides information on the proper fit of the helmet with the player's head during game practice and play in the field.

This information from the pressure-sensitive cap helps helmet manufacturers to develop helmet products that are custom-fit to the player's head size and shape. This will potentially decrease the severity of many injuries sustained by the athlete's head that can be attributed to the improper fit of the helmet.

What's next for the team at Western Michigan University?

Our team is currently working on improving the wireless data transmission capability of the fit cap and graphical user interface (GUI) of the software. We will also expand the usage of our sensors into more wearables and tactile sensing systems, for example, for posture monitoring in ergonomic chairs and insoles.

Where can readers find more information?

Readers can access the journal, Highly Sensitive Porous PDMS-Based Capacitive Pressure Sensors Fabricated on Fabric Platform for Wearable Applications, here.

About the Team

Dr. Massood Z. Atashbar is a Professor at the Electrical and Computer Engineering (ECE) Department, Western Michigan University. He is the lead faculty for NextFlex at Western Michigan University and is the director of the Center for Advanced Smart Sensors and Structures (CASSS), Center for the Advancement of Printed Electronics (CAPE), and Sensor Technology Laboratory.

Dr. Massood Z. Atashbar is a Professor at the Electrical and Computer Engineering (ECE) Department, Western Michigan University. He is the lead faculty for NextFlex at Western Michigan University and is the director of the Center for Advanced Smart Sensors and Structures (CASSS), Center for the Advancement of Printed Electronics (CAPE), and Sensor Technology Laboratory.

Dr. Atashbar's expertise is in all aspects of design, micro/nano-fabrication, and characterization of high-performance sensing systems, microfluidic devices, printed electronics devices, and BioMEMS devices for applications in the biomedical, environmental, and defense industries.

He has published over 280 refereed articles, refereed conference proceedings, and 4 book chapters. In addition, Dr. Atashbar has published 9 patents and more than 30 invention disclosures. He has managed several research programs funded by US federal agencies, industries, and other sources totaling millions of dollars.

He currently serves as PI or Co-PI for several funded research grants with a total value of over $14M. Dr. Atashbar has been a recipient of the College of Engineering and Applied Science Outstanding Researcher Award in 2017, Western Michigan University Outstanding Innovation award in 2018, State of Michigan's 2019 SmartZone Best Small Business Honoree for the development of an FHE-based smart helmet impact detection system, and State of Michigan's 2021 Best Small Business Award. He is currently serving as a member of the technical council committee and is a co-chair of the technical working group for NextFlex.

Simin Masihi is currently a Ph.D. candidate in the department of ECE at Western Michigan University. Masoud Panahi is currently pursuing his Master's degree in Electrical Engineering at WMU. Both Simin and Masoud are currently working as teaching assistants in the Department of Electrical and Computer Engineering and research assistants at the CASSS. Their research is focused on developing smart flexible and highly sensitive wearable sensor structures for medical and health monitoring applications.

Dr. Dinesh Maddipatla is currently working as a post-doctoral research associate in the ECE department at WMU and his research interests are focused in the area of FHE for the development of printed electronic devices for applications in the biomedical and environmental industries. He has published over 70 peer-reviewed journals and conference publications, 3 patents, and 13 invention disclosures.

Anthony Hanson received his Master's degree from the ECE department and is currently working as a research associate at WMU. He is a member of Tau Beta Pi and is very enthusiastic about developing sensors using flexible electronics. His research interest includes sensor applications, embedded systems, and sensor acquisition methods.

Dr. Binu Narakathu is the co-founder and president of SafeSense Technologies. He is the author of more than 150 articles in peer-reviewed journals and conference publications. In addition, he has published 9 patents and more than 30 invention disclosures. Dr. Narakathu has been a recipient of State of Michigan's 2019 SmartZone Best Small Business Honoree for the development of an FHE-based smart helmet impact detection system, and State of Michigan's 2021 Best Small Business Award.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.