This application note explores how plant efficiency can be improved using cloud-based inventory software and the Industrial Internet of things, harnessing the power of simple software and the latest level sensor technology in order to reduce production stoppages and material shortages.

Image Credit: BinMaster

BinMaster: Creating Solutions for Industry

Historically, operational processes like monitoring inventory in bins, tanks and silos can be time-consuming, unsafe and tedious tasks. It is essential, however, when monitoring inventory to know how much material is in each vessel.

Plants processing powders and solids, along with liquids stored in tanks, bins, silos or IBCs, risk having high levels of unwanted inventory discrepancies, which can create production headaches along with negatively impacting profitability.

Image Credit: BinMaster

Workers everywhere are familiar with the same experiences: from grabbing their coats to exiting the premises; to climbing every silo, writing down the measurements and returning to the office to mark them down.

The usual procedure continues: entering each hastily-scribbled reading into the spreadsheet, emailing them to the usual recipients and finally, hours later, having an accurate inventory. Then the typical experience of freaking out, placing last-minute orders and running out of material.

Image Credit: BinMaster

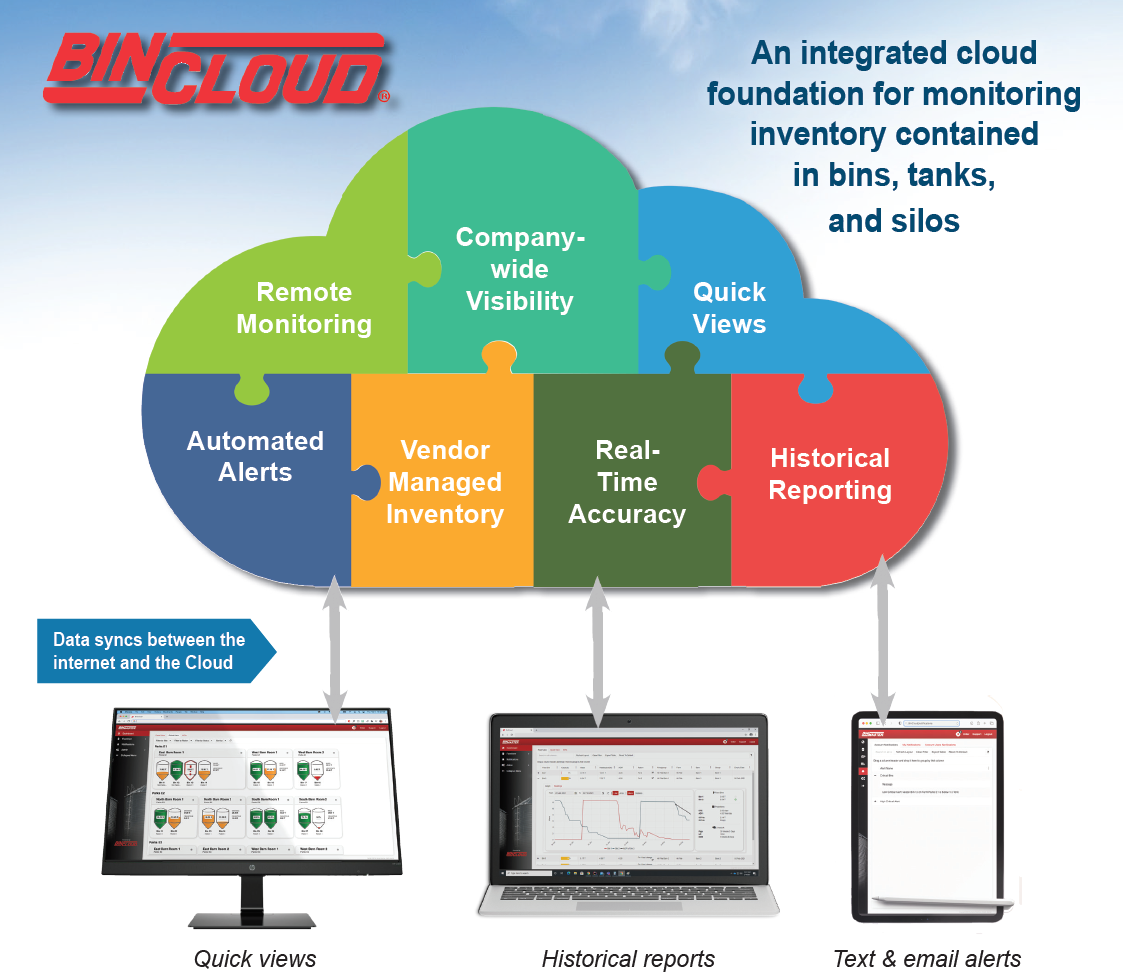

A new version of the scenario has emerged, thanks to BinMaster. The worker can simply arrive at work and log in to a centralized database showing their silo inventory company-wide. They are able to address low-level alerts – and their coworkers can do the same.

The company can rest easy, knowing that inventory benefits from continuous updates and workers are alerted when materials get low.

Image Credit: BinMaster

How Cloud Computing Benefits You

Combining advanced level sensor technology and cloud-based Software is a simple way to streamline inventory and supply chain management easier.

Image Credit: BinMaster

Accessibility: The information is available anywhere there is internet access from a tablet, phone or PC, while information is portable.

Accurate Information: Fewer discrepancies, total transparency and more information naturally leads to better decisions. Clients know what they need to buy and when they need to order it.

Better Control: Automation facilitates minimal human intervention, faster, more accurate and timelier outputs and centralized digital control.

Cost Containment: Both direct and indirect. Automation of day-to-day tasks means less overtime and fewer inefficiencies without risking any emergency or late delivery charges.

Historical Reporting: Manage and segregate long lead time, high-turn and materials which have strict reporting requirements.

Improved Monitoring: Receive reports in real-time of on-hand supply and easily forecast when you will run out – ensuring accuracy thanks to the fact that data is continuously updated almost effortlessly.

Job Satisfaction: Workers enjoy a less mundane day-to-day, with more time spared for challenges like planning and problem-solving.

Optimize Production Processes: You are able to streamline essential communications between all personnel and devices in order to ensure clarity and accuracy throughout.

Process Improvements: With the process improvements of reducing material outages and production stoppages as a result of shortages, and batch processing errors, better quality results.

Security: Both past and present data are stored safely and securely.

Simplicity: Simplicity is key – where there are no servers and no IT department, programming updates are simply undertaken by the host provider, and there is no need-to-know programming in order to use the software.

Time Savings: Thanks to having fewer trips to the control room, less time on the phone, less time managing spreadsheets, workers spend less time doing mundane routine or redundant tasks.

Image Credit: BinMaster

Image Credit: BinMaster

Level Sensors Play a Leading Role

Cloud-based programs have the advantage of being compatible with a variety of measurement technologies and sensors. Thanks to this versatility, they are able to be used in conjunction with vessels that have a huge range of different shapes and sizes and capable of storing all types of powders, solids, or liquids.

Better Accuracy: The majority of level sensors are accurate within a distance of 0.2” measured

Improved Safety: The need for climbing is eliminated with automated measurements

Time Saving: Fewer people are required as more measurements are undertaken with less manpower

3D Level Scanner

Multiple points on the material surface are measured and mapped by this non-contact technology, which accounts for irregularities in calculating volume. 3D visualization and multiple vessel monitoring are provided by a specialized software program.

Image Credit: BinMaster

Non-Contact Radar

Superior level measurement is provided by 80 GHz non-contact radar in powders and solid, which are extremely dusty. Models that are designed for liquids can perform equally well in excessive steam, vapor, condensation and surface foam.

Image Credit: BinMaster

SmartBob

The sensor works like an automated tape measure, at timed intervals dropping a weighted cable to a solid material surface, as well as being able to measure the level of submersed solid material that has settled below a liquid surface.

Image Credit: BinMaster

Laser

Measuring in a tight beam, lasers are ideal for use on narrow vessels and either low-dust or no-dust environments. Wiring costs are reduced by battery-powered models, and installation is allowed for where power is either unavailable or limited.

Image Credit: BinMaster

Guided-Wave Radar

When it comes to models for measuring either liquids or solids, guided wave radar uses a cable suspended into the vessel to measure levels. Guided wave radar can be used for interface measurements detecting the level of separated layers.

Image Credit: BinMaster

How Industry is Benefitted by the Cloud

There are numerous examples of how plant processes can be improved by the Cloud. Why not see how it can help you?

Feed: Feed outages can be eliminated along with late delivery charges, and growers can better manage rations by projecting consumption growers. This additionally ensures there is less feed leftover at closeout, which reduces disposal charges and vacuuming.

Plastics: BinMaster offers real-time monitoring of the resins that go into the production process. Enjoy improved supply chain management, thanks to vendor-managed inventory with resin suppliers, along with an optimizing scheduling of deliveries.

Cement: Multiple batch plant locations are monitored and centralized on a database while logistics are improved and drivers’ routes scheduled, ensuring the entire truckload with fit into silos and improved coordination with fly ash suppliers.

Food Processing: Inventory management is offered for raw ingredient, WIP and finished product silos and buying power is leveraged by ordering for multiple plants on a single contract, along with batch processing of foodstuffs.

Fertilizer: Inventory tracking of powder, liquid and solid chemicals is facilitated, thanks to the use of historical reporting to track carrying costs and inventory turns in preparation for seasonal production and distribution.

Chemicals: Inventory tracking of regulated chemicals is facilitated, guaranteeing that chemicals are used in advance of their shelf life expiry in order to reduce disposal costs and resulting in an automated audit trail of chemical usage.

Wood Pulp Paper: Hog fuel storage bins, facilities for pellet production and sawdust bins are emptied in order to prevent stoppages or delays in production, and it is ensured that water, pulp and bleach levels are sufficient for paper production and the management of mill-to-mill transfers.

Agriculture: Storage bin capacity is optimized, audits and USDA reporting prepared, spreadsheets at grain elevators eliminated, grains valued, oilseeds and other commodities for export, railcar logistics.

Propane: The impact of weather on consumption is projected by historical reporting, storage facilities supply planned, tracking stored propane at multiple depot locations and routing of commercial and residential deliveries is facilitated.

Image Credit: BinMaster

Image Credit: BinMaster

Image Credit: BinMaster

Transform Tank and Silo Inventory

Image Credit: BinMaster

This information has been sourced, reviewed and adapted from materials provided by BinMaster.

For more information on this source, please visit BinMaster.