The IoT Wave of Change is Gaining Momentum

The terms Internet of Things (IoT) and Industrial Internet of Things (IIoT) broadly define a web-based network of smart devices communicating effectively with one another without direct human intervention.

Whether it’s temperature fluctuations, shifts in motion or even a change in force, sensing technology that continuously monitors an environment is embedded into devices in an IoT world.

For design engineers, it’s no longer satisfactory to design a product or device that just does a job on command. In an IoT world, it must do its job when it is necessary. IoT represents a tide of change that ushers in a number of new challenges for design engineers of today’s smart products.

Companies that invest in methods to embed sensing technology into products and devices will now be regarded as the leaders in this technological shift.

Thin and flexible tactile force sensors, such as FlexiForce ™ sensors, allow products to become smart products, thus getting them ready to be incorporated into smart-connected applications.

While some sensors are designed to see or hear the world around them, FlexiForce sensors can become the device’s sense of touch to detect changes in their tactile environment and create an appropriate response.

This article will detail the technology that makes FlexiForce sensors and the features that mean they are the ideal embedded force sensing option to improve smart-connected products and applications. It will also offer conceptual examples of how this technology can be integrated into smart products and preparing them to ride the flow of the changing tide of the IoT.

Image Credit: Tekscan, Inc.

What Makes a Smart Connected Device?

The term “smart” is a well-known buzzword typically used to describe products, devices or systems that incorporate sensing technology to collect data and offer feedback. As technology has progressed, today’s smart products have become increasingly automated and demand less human interaction to function.

To become a smart-connected device – one optimized for an IoT environment – the device must incorporate sensing technology that performs its data-driven response by primarily connecting with other devices.

In the long run, this engenders a dynamic web-based communication system that streamlines repetitive tasks that people would normally have to perform. Smart-connected devices offer added value by eradicating any guesswork and sustaining consistency across a given process.

Force sensing can play a key role in helping a device become a smart connected device. Each touch offers vital information and data, and force sensors can translate this data into an actionable response.

Applications that can be Enhanced with Force Sensing Technology

- Industrial Controls

- Medical Devices

- Robotics

- Security Systems

- Supply Chain Tools

- Stylus and Writing Devices

- Training Devices

Benefits of a Flexiforce Sensor

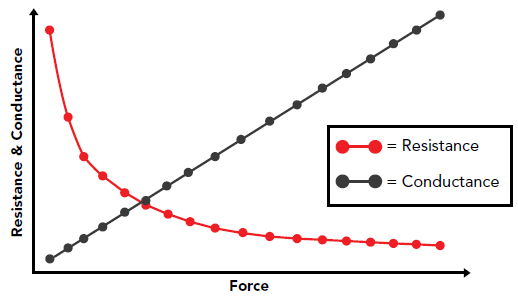

In an electrical circuit, FlexiForce sensors serve as a force sensing resistor. When the force sensor is unloaded, its resistance is extremely high. When force is applied to the sensor, this resistance is reduced. Any changes in resistance can be customized depending on application requirements.

Image Credit: Tekscan, Inc.

Thin & Flexible

- Paper-thin construction

- Unobtrusive; can be embedded in small spaces

Durable

- High temperature options available (up to 204 °C)

- Works in most operating environments

Low Power

- More energy efficient than other alternatives

- Only simple electronics needed

Variety

- Customizable solutions

- Various standard sensor sizes are available

Image Credit: Tekscan, Inc.

What are Flexiforce Sensors?

FlexiForce tactile force sensors are ultra-thin and flexible printed circuits, which can be integrated easily into force measurement applications. They are typically used to measure the force between any two surfaces.

FlexiForce sensors are perfect for OEM products due to Tekscan’s capacity to customize for an application’s particular needs:

- Geometry: FlexiForce sensors can be designed in various shapes and sizes to meet any application and product’s exact needs.

- Ink technology: Tekscan supplies three pressure-sensitive ink variations: standard, enhanced and high temperature.

- Integration support: Tekscan’s team of mechanical, electrical and application engineers possess vast experience assisting design engineers in helping them realize successful product integration

IoT Concepts with FlexiForce Sensors

There are six concepts where FlexiForce sensors can offer a sense of touch to drive IoT processes. Many of these concepts entail current embedded FlexiForce applications.

1. Innovate Medical Recovery Devices and Procedures

FlexiForce sensors help get patients on a fast and secure road to recovery. Patients undergoing therapy for an injury or medical procedure are given particular instructions by their physicians to help improve and enhance the rehabilitation process.

Since physicians do not have the capacity to be with their patients at all times, embedding touch sensors into medical or therapeutic equipment can help them monitor patients while they are on the move.

Case Example: Rehabilitation Equipment to Keep Doctors Close

Significant injuries typically necessitate a significant change in a patient’s day-to-day activity to accommodate a treatment plan. Doctors may tell their patients to limit or change the way they move to reduce risks of additional complications.

Patients that need crutches after an injury or medical procedure put stress on other parts of their body in order to get about. As an IoT application, FlexiForce sensors fitted in the contact areas of crutches can be used to transmit data signals to the physician’s computer or mobile device.

This signal transmits real-time information on how the patient is using the equipment. With this data, the physician can then inform their patient and offer suggestions that can help reduce soreness or other potential risks. This can all be achieved without scheduling an office visit.

Image Credit: Tekscan, Inc.

Other Similar Applications:

- Bed or chair monitoring

- Drug delivery

- Walkers

- Wheelchairs

2. Help Aging Loved Ones Live Independently

FlexiForce sensors help keep friends and families close, even when distance and time separate them. Adults aged 65 and older make up a large and growing portion of the global population.

Incorporating touch sensors into products or devices can assist the aging population and help them live more independent lives. Actionable data regarding their routine can then be transmitted to friends and family members.

Case Example: Smart Connected Furniture Helps Friends and Families Rest Easy

Elderly people that have or are at risk of health conditions such as dementia may require extra attention for their safety. Sometimes financial and other commitments can make it extremely difficult for friends and families to deliver the close contact their loved ones need.

Incorporating FlexiForce sensors into furniture can help inform emergency contacts of any unusual changes in an individual’s routine.

In one IoT application, a bed that is fitted with FlexiForce sensors can help run a communication system that sends text alerts to emergency contacts or sends a notification to authorities when an individual leaves their bed for a concerning period of time.

This noninvasive system can help ease any concerns and keep loved ones safe and secure.

Image Credit: Tekscan, Inc.

Other Similar Applications:

- Doormats

- In-sole shoe sensor applications

- Vehicle seats

3. Improve Supply Chain Processes

FlexiForce sensors can streamline routine business touch points and improve operations. Inventory management is a time-consuming part of any business operation that sells or ships its products. However, including touch sensors into certain supply chain processes or equipment can offer crucial information that guarantees accuracy and customer satisfaction.

Case Example: The On-The-Shelf Inventory Manager

Brick and mortar businesses experience constant changes in force that can happen on a store floor. With force sensing technology, business managers and their suppliers can acquire actionable inventory data using such changes in force, which would usually have to be collected through time-consuming checkups.

Incorporating FlexiForce sensors into store shelves can track any changes in force/weight instantly, which can help indicate how much product is in stock.

In an IoT application, after a certain amount of product units have been removed from the shelves, a signal – such as an e-mail, text message or automated phone message – can be transmitted to the store owner or distribution center to schedule the next delivery automatically.

This can considerably reduce time spent on managing inventory while meeting demands for particular products.

Image Credit: Tekscan, Inc.

Other Similar Applications:

- Checkout counters

- Monitoring weight distribution on delivery vehicles

- Production line control systems

- Smart product packaging

- Theft management

4. Monitor Athletic Performance

FlexiForce sensors can keep athletes and their coaches mindful of their workload. When the game is on the line and adrenaline is pumping, athletes will typically push their limits to perform, with little concern for any potential health impacts.

Touch sensors embedded into their equipment can collect valuable information and data on what the athletes are experiencing on the field.

Case Example: Footwear to Minimize Player Health Risks

In team sports, the coaches’ have the responsibility to keep their players safe. Maintaining a healthy rotation of playing time ensures that players are not overstraining themselves to hazardous levels.

Embedding FlexiForce sensors into a player’s shoes can collect key information to help coaches manage their team’s workload.

As an IoT application, an alert can be generated for a player that has been on the field for a significant amount of time using the force sensor data. This data is then sent to the coaching staff to indicate that a player should be substituted for their safety.

This is of particular importance in extreme outdoor weather conditions, where rest and hydration may be overlooked during intense competition.

Image Credit: Tekscan, Inc.

Other Similar Applications:

- Gloves to enhance grip

- Instrumented protective gear

- Protective leg or arm braces

- Sports helmets

5. Enhance Safety in High-Risk Environments

FlexiForce sensors can’t stop disasters from happening, but they can be utilized to alert emergency response systems instantly when extreme force impacts occur. In hazardous occupations, it is of vital importance to provide the appropriate safety equipment to employees to keep them as safe as possible while on duty.

Embedding touch sensors into safety equipment can help make sure that the necessary emergency procedures are initiated the moment a disaster strikes.

Case Example: Military Helmets that Quantify Impacts

The lives of military servicemen and women are at risk every day while on active duty. Uniforms and equipment with integrated force sensing technology can be used to help control a life-saving communication system whenever a significant impact occurs.

In an IoT application, military helmets fitted with FlexiForce sensors and synchronized with an accelerometer can transmit force data with information that instantly indicates the approximate force impact the soldier’s helmet has experienced.

If the particular impact exceeds a calibrated force threshold, medical personnel can be instantly alerted to treat the individual.

Image Credit: Tekscan, Inc.

Other Similar Applications:

- Automobile collision safety

- Robotic assembly control & safety

- Seat restraints

6. Coordinate Workforce from a Distance

FlexiForce sensors can help business managers maintain control of their employees and their equipment. In businesses where employees are on the move, it’s crucial that owners know their workforce is performing to expectations.

Embedding touch sensors into industrial vehicles can offer verifiable data on employee activity, a clear overview of productivity and proof that workers are in compliance with safety protocols.

Case Example: Monitoring an Employee Workday

Work-related vehicles, such as forklifts, necessitate considerable capital investment. Dysfunctional or mistreated industrial vehicles can cause accidents on the floor, resulting in injury and loss. FlexiForce sensors embedded into forklift seats can help collect data on who is using the vehicle and how they are using it.

Calibration of the sensors can be set to a specific weight value so that once the value is reached, the forklift would recognize the presence of an operator. In an IoT application, business managers would receive alerts activated by tactile force sensors within the vehicle.

This offers critical safety and workflow data. This process can also be collected by cloud-based employee management systems.

Image Credit: Tekscan, Inc.

Other Similar Applications:

- Controlling inventory distribution

- Monitoring drivers/passengers in transportation applications

- Tool and asset management

- Tracking time at work

Conclusion

Is Your Product Ready to Ride the IoT Wave?

Now is the time to think about how embedding force sensing technology into your product will give you a competitive edge. There are four questions to consider as you begin your process:

- What force sensing technology can be incorporated into my product design effectively and economically?

- What mechanical or electrical obstacles or requirements may influence my choice of force sensing technology?

- Does my product require capturing force within a particular sensitivity range?

- Is my choice of force sensor backed with a support group of expert engineers experienced in embedding force sensing technology?

Image Credit: Tekscan, Inc.

If you are ready to take the plunge into IoT with FlexiForce sensors, then start a conversation with Tekscan today. Tekscan is a company that understands the challenges design engineers face, and the risks they encounter when embedding new technology.

Whether it’s a standard FlexiForce sensor or a custom design, Tekscan has a track record proven for helping design engineers accomplish high-value products with force sensing technology. Your return on investment comes in the form of confidence in your product design, a reduced development process time and an enhanced end-user experience.

This information has been sourced, reviewed and adapted from materials provided by Tekscan, Inc.

For more information on this source, please visit Tekscan, Inc.