The IIoT (Industrial Internet of Things) has completely overhauled the way we do things by making everyday, ordinary devices smart and daily tasks more efficient. From smartphones to smart doorbells, smart technology is becoming a pervasive force offering solutions across an expanding number of markets.

Yet, in spite of these advanced capabilities, which have ushered in an age of enhanced productivity and conveniences, the safety world lagged behind, but not anymore. Fire services, utilities, oil and gas, and industrial organizations have made the transition towards a smarter, more connected world. They have done this for one simple reason:

The Connectivity Advantage: Visibility

The safety statistics around a pre-connectivity era are staggering. Almost 3 million injuries occur in the workplace annually, costing companies around $171 billion in lost productivity, wages and medical expenses.

What is more, between 80-90% of these injuries result from human error. While smart technology is not 100% perfect, these technologies are demonstrating their capacity to reduce the potential for human error.

With automated alarms, remote access and instant data visualization, a connected Safety Program outperforms human capabilities most of the time. A networked Safety Program with a 360-degree connection between worksites, workers and workflows allows safety-focused organizations to find more innovative ways to mitigate risk.

Connected and Protected

Information is crucial when it comes to preventing crises and responding to emergencies. Without access to information, critical questions go unanswered like: Is this a true emergency or is it a false alarm? Where is it happening? What is happening? Do we need to investigate or evacuate?

For Safety Managers, the pressure rests on knowing that something is happening while not knowing exactly what: without connectivity, this happens more often than necessary.

Fortunately, connectivity is balancing things out by allowing any authorized person to participate in value-added, time-saving, safety-promoting activities, even if located remotely.

This includes the following benefits:

- Automation of processes and systems

- Situational awareness of workers and equipment

- Remote access to information and data sources

- Notifications, alarms and alerts about manned and unmanned locations

Image Credit: MSA - The Safety Company

Adaptable, Proactive Safety Programs

Worker safety is absolutely vital, and so is saving time and money. By incorporating IIoT smart-enabled technologies, organizations can improve predictive maintenance and optimize operations. With connectivity, Safety Managers get much-needed insight that can be the motive behind analytical, life-saving decision-making.

Without insight, it is difficult for Safety Managers to troubleshoot a problem, overcome challenges and protect workers from hazards. Connectivity helps improve processes, accelerate functions and broaden the scope of the Safety Program.

The data produced from an interconnected workplace is both reliable and actionable. The work environment is more efficient and thereby a safer place to be.

Moreover, profitability needs are in close alignment with safety goals. If done correctly, secure connectivity can offer Safety Managers peace of mind and allow them to focus on the larger goals of the overall Safety Program.

Enabling Autonomous Operation

Managing individual devices is part and parcel of daily life in the world of safety. However, an interconnected Safety Program helps tackle the problem of transforming a disparate network of field devices and variable data streams into a single, easy-to-manage system with smart, basic connection among devices, data sources and decision-makers.

For instance, oil and gas, wastewater and alternative fuel companies that have operations spread across a number of different locations, including offshore and remote facilities, are faced with unique challenges. The greatest challenges outside of market volatility are operational resiliency and workforce shortages.

The insufficiency of an available skilled labor force often acts as the impetus for seeking alternatives to being solely dependent on human capital. For many, this means building technological innovations into operations – namely IIoT solutions – that facilitate autonomous operation.

The Significance of Remote Notifications

IIoT is central to transitioning towards autonomous operations that are both smarter and safer. Combining advanced fixed gas and flame detection (FGFD) sensors with remote monitoring capabilities enables organizations to access instantaneous insights that allow production to keep going while protecting workers.

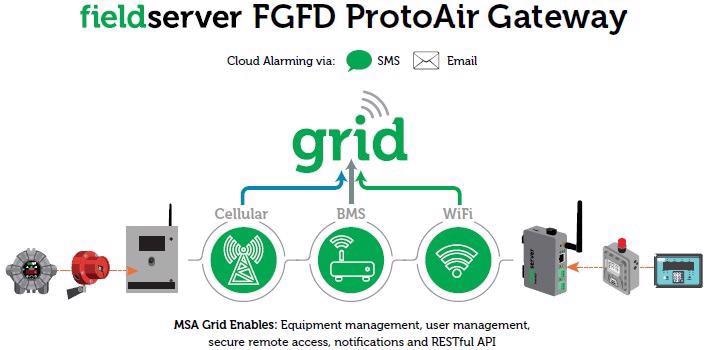

For instance, MSA FieldServer partners with O&G companies to rapidly deliver reliable analytics data, diagnostics and updates via the FieldServer FGFD ProtoAir wireless gateway and MSA’s IIoT Cloud Platform or other third-party cloud solutions.

Besides automatically uploading calibration modifications and firmware updates, this kind of IIoT solution also provides answers to these questions:

How do we inform the appropriate people at the appropriate time about a potentially hazardous situation when no one is on-site to assist? How do we do it affordably and reliably?

The “how” for the MSA FieldServer FGFD ProtoAir wireless gateway is by remotely delivering alerts, reminders, updates, alarms and other notifications to the appropriate personnel independent of network or internet availability so that decision-makers can remotely:

- Inspect critical infrastructure and monitor for breaches

- Identify early warning signs to prevent operational failure, disruption and high-risk conditions

- Evaluate potential worker hazards and risks, such as spills and gases that can lead to explosions

- Eliminate personnel, time and network dependencies to ensure real-time, around-the-clock situational awareness

Image Credit: MSA - The Safety Company

The Rewards of Connectivity

There are a number of productivity and cost benefits of incorporating IIoT solutions into operations, including:

- Helps to enhance safety by supplying visibility into potentially hazardous situations

- Improves communication, alerting key stakeholders in real-time about alarms, threats and other perilous circumstances

- Minimizes downtime, including production shutdowns resulting from the need for in-person investigations

- Saves time and expenses related to manning remote locations and deploying personnel for on-site inspection

- Provides critical and more accurate insight, so that assets remain operational and decision-makers stay informed

Connectivity Challenges

While there are a vast number of advantages that smart technologies and improved connectivity offer, they are not impenetrable to the potential risk of IIoT security breaches. These can include a broad range of unauthorized activities, from the illegal acquisition of sensitive data such as worker location by hacking into a network system.

Fortunately, connectivity risks can be mitigated and prevented with the right toolbox and know-how. Here’s an overview of what should be considered to help safeguard any connected Safety Program and prevent the risk of disruption and destruction by cybercriminals:

- Employ industry-standard password policies and require user verification

- Implement a detailed incident response plan: There are a number of questions to ask your solutions provider. MSA can help users better understand cybersecurity in relation to a connected solution.

- Limit usage to authorized users with an advanced set of encryption and logging features

- Require annual penetration and vulnerability testing on devices, applications, infrastructure and APIs

- Restrict network and data access with encryption and Virtual Private Network (VPN) tunnels

Conclusion

When monitoring and managing worker and workplace safety, it’s absolutely crucial to eliminate any clear and present danger and potential obstacles.

An IIoT solution such as the FieldServer FGFD ProtoAir effectively removes any problematic questions from the operational equation, such as “Who do we call?” and “What do we do now?”

Whether combined with MSA Modbus and BACnet FGFD devices or devices from other manufacturers, the FieldServer FGFD ProtoAir facilitates remote monitoring, control, SMS or email alarm notifications, data visualization and supports all major cellular networks.

Most crucially, it means that safety professionals have the capacity to leverage connected technologies for a more proactive safety culture.

References and Further Reading:

- MSA, https://us.msasafety.com/connected-work/connectivity., Accessed October 2021.

- IoT for All, https://www.iotforall.com/iot-applications-oil-and-gas-industry., Accessed October 2021.

- CIO Review, https://www.cioreview.com/news/how-iot-solutions-are-reshaping-the-oil-and-gas-industry-nid-34480-cid-35. Accessed October 2021.

- McKinsey & Company, https://www.mckinsey.com/industries/oil-and-gas/our-insights/the-autonomous-plant-entering-a-new-digital-era. Accessed October 2021.

- Achieving the Benefits of Remote Connectivity Faster and More Reliably. (2020, December 8.) MSA FieldServer Blog. Retrieved October 2021 from https://blog.sierramonitor.com/

- Five Steps to Autonomous Operations for Oil and Gas. (2018, December 31.) Forbes. Retrieved October 2021 from https://www.forbes.com/?sh=5dfab89b2254

This information has been sourced, reviewed and adapted from materials provided by MSA - The Safety Company.

For more information on this source, please visit MSA - The Safety Company.