Phosgene Detectors were supplied by IGD to a pharmaceutical company in the United Kingdom to assist in reducing their phosgene gas hazards. The efficient Phosgene Detector met all of the client’s requirements and proved to be noticeably better for their application.

Image Credit: International Gas Detectors Ltd

This article provides more information on this one-of-a-kind gas hazard for pharmaceutical applications.

What was the Application and Why was a Phosgene Detector Required?

This pharmaceutical company needed the Phosgene Detector because an experiment was taking place on-site. The pharmaceutical industry creates a wide range of drugs and medicines, and this specific company is constantly experimenting to develop a more effective drug.

Phosgene gas was being released from a nearby fume cupboard as part of the experiment. This was a possible threat because if the fume cupboard malfunctioned or became blocked, toxic phosgene could build up.

Pharmaceutical technician working on the production of pills. Image Credit: International Gas Detectors Ltd

Why are Phosgene Detectors so Important?

Phosgene gas is a pale yellow, colorless or white gas that has a pleasant odor similar to freshly cut hay at low concentrations but a foul odor at high concentrations. This gas is highly poisonous and heavier than air at room temperature.

Phosgene gas is not produced naturally, it is mostly used in industrial settings. It is used in the manufacture of pharmaceuticals, plastics and pesticides, and can be emitted as a result of the production of various chemicals.

Phosgene is transported in liquid form, which is cooled and pressurized before being stored in metal cylinders. When a leak occurs, phosgene transforms into the gaseous state, which stays close to the ground and spreads quickly.

As a result, a massive build-up of this gas may go unnoticed. Due to the toxicity of this gas, it can be extremely dangerous to personnel.

Laboratory worker conducting tests wearing the UNI. Image Credit: International Gas Detectors Ltd

Phosgene has a STEL limit of 0.02 ppm and a TWA of 0.06 ppm, both of which are relatively low levels, showing how dangerous phosgene is to human health.

During World War I, phosgene gas was primarily used as a choking agent, ultimately being responsible for the vast majority of deaths during this period.

Burning in the eyes and throat, coughing and skin lesions are all symptoms of phosgene poisoning. Chronic bronchitis and emphysema are two long-term effects.

As a result, it was crucial that the pharmaceutical company installed phosgene detectors to reduce the risk as much as possible.

IGDs Detectably Better Phosgene Detector Solution

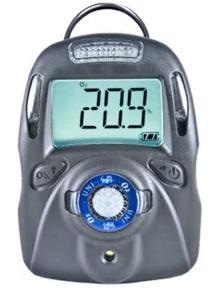

IGD provided the company with the UNI portable Phosgene Detector, which is a noticeably better solution for phosgene. This ensured their personnel’s safety by providing each team member with their own personal gas detection device.

The company was very pleased with the device’s durability, lightweight, flexibility and three-year battery life. This meant that the Phosgene Detectors would not interfere with the team’s work during the day, making their safety as simple and comfortable as possible.

UNI portable gas detector. Image Credit: International Gas Detectors Ltd

With its long warranty period, IGD could also make this device easy to service, keeping the Phosgene Detectors in top shape at no additional cost. The UNI includes 50 event data logging capabilities, allowing the client to easily track any events that may occur.

Conclusion

On the whole, the application of this device in the pharmaceutical company was a huge success. They were blown away by all of the extra benefits that IGD was able to provide with the UNI Phosgene Detector, in addition to the noticeably better service provided by IGD. IGD now has a huge opportunity to work with similar companies in the future to implement Phosgene Detectors as a result of this case study.

This information has been sourced, reviewed and adapted from materials provided by International Gas Detectors Ltd.

For more information on this source, please visit International Gas Detectors Ltd.