Due to the rapid development of the industrial sector, various industrial gases, such as nitrogen, oxygen, carbon dioxide, argon, hydrogen, helium, and acetylene, which are gaseous at normal temperatures and pressure and serve as the foundational raw materials for contemporary industry, are now completely indispensable to the operation process.

Industrial gases have a broad range of applications in a variety of sectors, including metallurgy, steel, medical treatment, petroleum, chemical industry, electronics, environmental protection, building materials, glass, construction, food, beverage, equipment, and so on.

However, as gas may be dangerous, it has more strict regulations for technologies related to preparation, container handling, storage, and transportation, among other things.

Image Credit: Micro Sensor Co., Ltd

Real-time monitoring of the pressure values in the manufacturing, storage, supply, and use of industrial gases is accomplished through a variety of pressure transmitters, differential pressure transmitters, and other sensing and monitoring instruments.

Gas production equipment and storage tanks are also realized through supporting systems. To guarantee safe production, enhance process management, and increase automation, gas cylinders must be automatically monitored and adjusted to maintain pressure values within the typical range.

Cryogenic Storage Tank Monitoring

When monitoring the storage tank, the pressure transmitter is primarily used to gauge the liquid level of liquid gas. The most popular and reliable method for determining the liquid level in cryogenic storage tanks is differential pressure measurement, using a differential pressure transmitter to measure the pressure difference between the tank’s top and bottom.

The height of the liquid level will ultimately be calculated from the recorded pressure value. To verify that the system is operating safely, the pressure sensor may also be used to detect the tank’s absolute pressure as well as the pressure before and after the cryopump.

Image Credit: Micro Sensor Co., Ltd

There Are Four Products Micro Sensor Can Offer for This Application

For measuring oxygen pressure, Micro Sensor typically employs an MDM4901FL differential pressure transmitter. The device employs an isolation diaphragm made of stainless steel 316 L that is filled with fluorinated oil for enhanced stability and safety.

The MPM489FL pressure transmitter is also available for use in this application. Fluorinated oil is used in the product’s sensing component, and the grease prohibited production method is used. It can detect gauge or absolute pressure. With short-circuit and reverse polarity protection, the MPM489FL is secure, dependable, and simple to use.

A dispersed silicon piezoresistive differential pressure sensor, as well as a stainless steel 316 L isolation diaphragm, are also components of the MDM4902FL I2C digital differential pressure transmitter. The product has a fluorinated oil filling for improved stability, a wide operating temperature range, high accuracy, steady performance, and easy adjustment. The docking and expansion are made simple by the I2C digital output standard.

A high-precision, high-stability differential pressure transmitter with a broad range and intelligent output is the MDM3051S-DP intelligent differential pressure transmitter. It can be used to measure the flow of a medium like gas or steam as well as the liquid level, density, pressure, and flow.

Compressed Gas Cylinder

Gas supply pipes and gas supply tanks are often monitored for pressure using pressure transmitters in gas cylinder monitoring.

To ensure gas cylinder safety, pressure transmitters are in charge of monitoring the pressure in gas cylinders and providing signal output to detect low tank pressures in system-critical applications.

The switchover manifold can be automatically controlled by the pressure transmitter, which can also be incorporated into the PLC alarm system to actively detect the cylinder pressure. To remotely monitor pressure fluctuations and avoid issues like stockouts or gas cylinder leaks, the pressure transmitter may also be linked to a telemetry gateway.

When pressure transmitters are used to monitor oxygen levels in patients, it is important to make sure that the device is well cleaned and that the oil used to fill the sensor is fluorinated and oxygen-compatible.

Image Credit: Micro Sensor Co., Ltd

For this application, Micro Sensor offers the MPM489FL pressure transmitter, approved with ATEX. The product uses a “no oil” manufacturing procedure and has a fluorinated oil-filled pressure sensor. Gauge pressure, absolute pressure, as well as sealed gauge pressure, may all be measured using it. Both short-circuit and reverse polarity protection are present. It is trustworthy, secure, and simple to use.

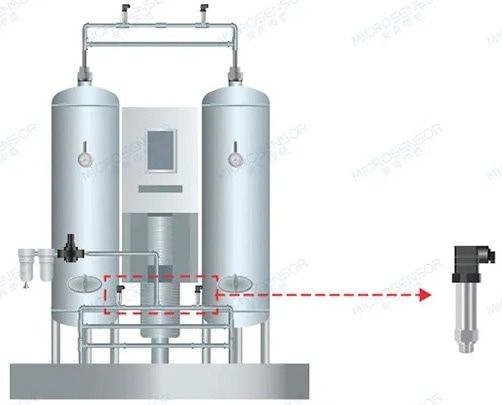

Nitrogen Generator/Oxygen Generator

Direct production and use of nitrogen generators and oxygen generators are more efficient than conserving nitrogen and oxygen in high-pressure cylinders.

The majority of industries that employ nitrogen/oxygen generators are those that deal with electronics, healthcare, air conditioning, cold storage, food, and beverage. The pressure transmitter on the nitrogen generator/oxygen generator is frequently used to monitor the pressure swing adsorption process in addition to monitoring the pressure within the container.

Image Credit: Micro Sensor Co., Ltd

The MPM489FL pressure transmitter approved with ATEX, is appropriate for this application.

Image Credit: Micro Sensor Co., Ltd

According to the real circumstances of various projects, Micro Sensor can offer expert monitoring solutions and customized products. Its skilled R&D team is able to provide customers with a one-of-a-kind service.

This information has been sourced, reviewed and adapted from materials provided by Micro Sensor Co., Ltd.

For more information on this source, please visit Micro Sensor Co., Ltd.