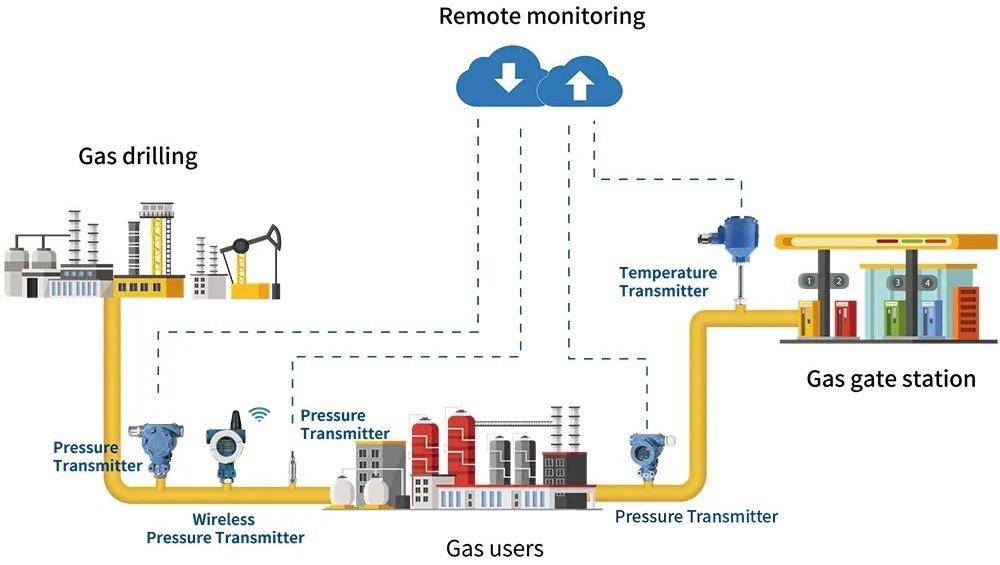

The installation of temperature and pressure sensor in the gas pipeline can monitor the real-time pipeline pressure and temperature parameters in the process of natural gas exploitation, transportation, metering and consuming.

Upon being integrated with the supporting system, it could realize remote monitoring and early warning, which can efficiently guarantee the safe operation of every gas system and is of great importance to realize automatic monitoring of the gas pipe network.

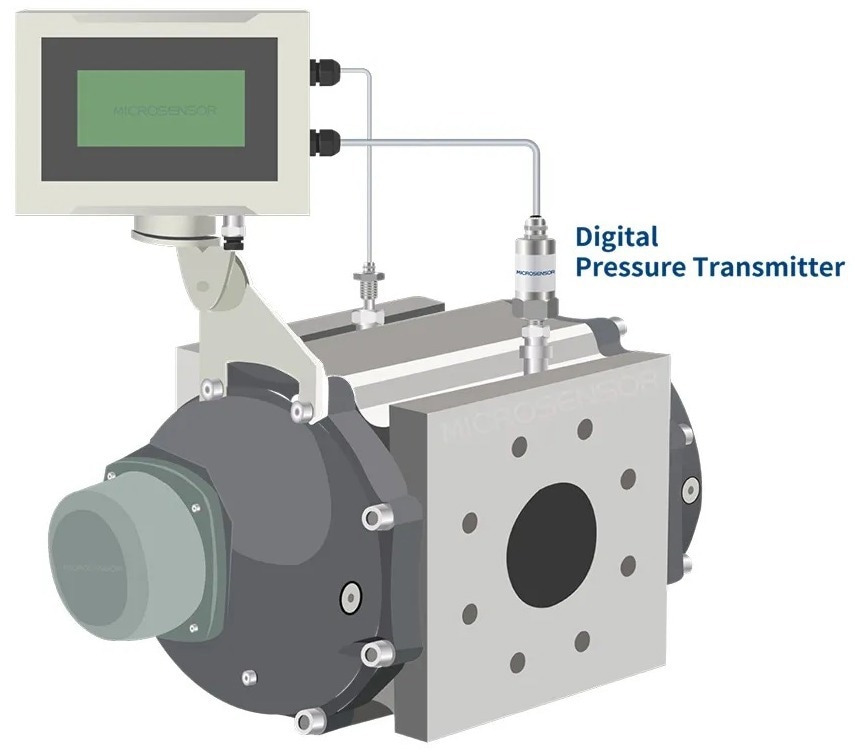

Gas Metering Instrument: Roots Flowmeter

Roots Flowmeter is one of the main pieces of equipment in the metering system of the city gas gate station. It can precisely quantify the natural gas flow in a few areas and is the key basis of the gas cost settlement.

The MPM3801A digital pressure sensor utilized in the root flowmeter possesses high precision compensation and testing equipment, executing high precision, consistency, and stability. Thus, it helps enhance the precision of flow monitoring.

Image Credit: Micro Sensor Co., Ltd

MPM3801A consists of high precision, standard I²C or SPI output, high stability, and 5uA low power consumption. It is 3.3 V or 5 V powered and features a compact size, and simple integration.

Derived from MPM3801A standard type, MPM3801GRF digital pressure sensor is specially designed for gas meter / roots flowmeter. It features standard I²C output, high precision, low power consumption, and high stability. MPM3801GRF has 3.3 V or 5 V powered. It uses thread mounting and electrical cable connection.

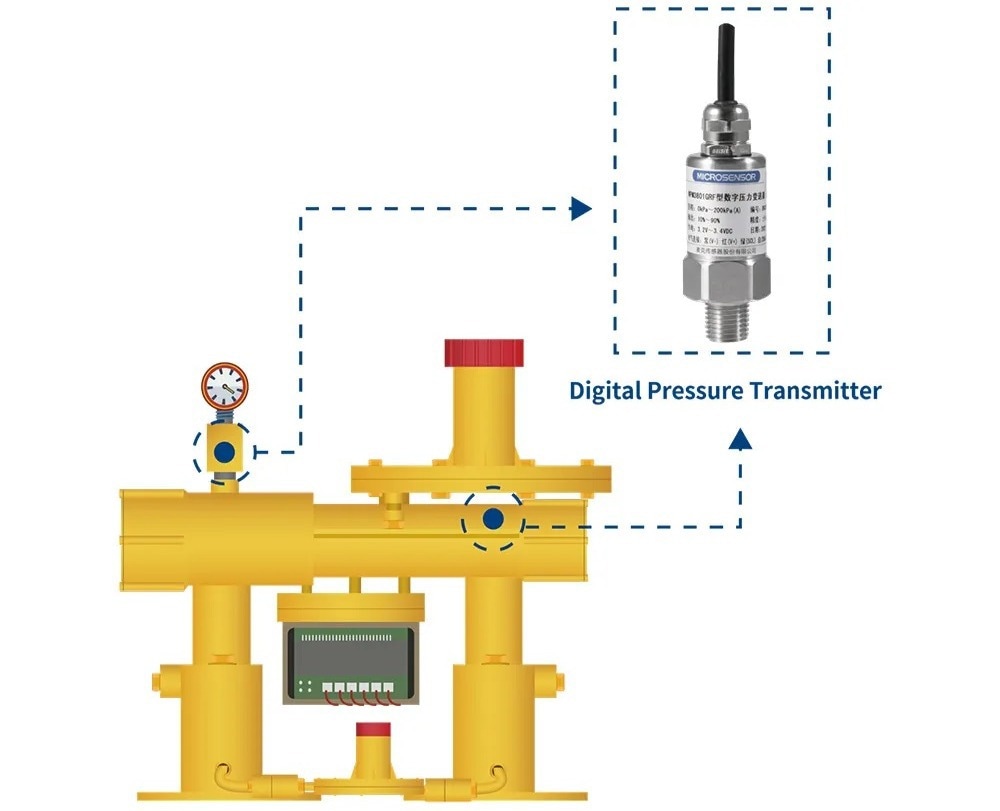

Gas Pressure Regulator: Smart Gas Pressure Regulator

The primary function of the gas regulator is to adapt the higher gas inlet pressure to the set lower gas outlet pressure, and with the alteration of gas consumption and the fluctuation of inlet pressure, automatically maintains the outlet pressure value in a few ranges and plays the role of decreasing and retaining pressure.

Pressure transmitter installed at the gas inlet and outlet, could be key component to monitor performance of the pressure regulator.

Image Credit: Micro Sensor Co., Ltd

In this application, analog or digital pressure transmitters are available. MPM489 pressure transmitter has analog output, approved with ATEX and SIL2. MPM3801A digital pressure sensor has standard I²C output, high stability low power consumption, and high accuracy. It is 3.3 V or 5 V power supplied and could be thread mounting with component structure.

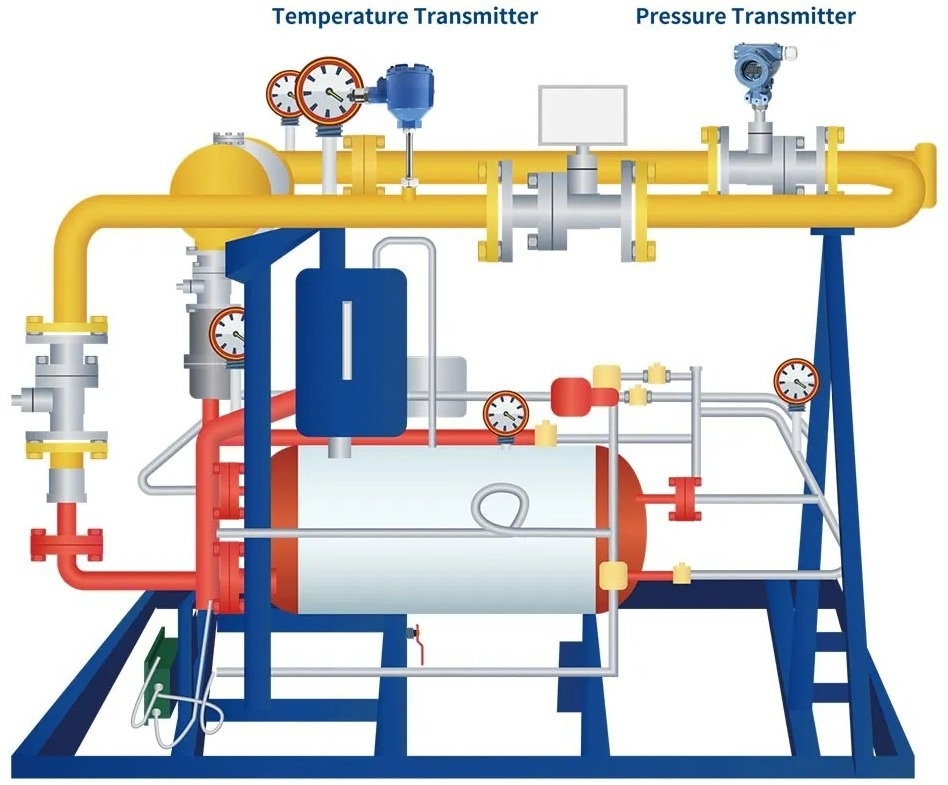

Gas Skid-Mounted Equipment

Gas skid-mounted equipment is the main equipment utilized in gas distribution. The equipment has been fitted with temperature and pressure transmitters to track the quantified pressure and temperature parameters in real-time, and remotely send them to the main control room, which has the potential to detect and deal with deviations to guarantee that the equipment and system function in a normal manner.

Micro Sensor offers MPM483CNG/DM pressure transmitter, MDM7000 smart (differential) pressure transmitter, MPM489CNG pressure transmitter, and MTM4831 temperature transmitter to obtain a precise measurement of gas disguise equipment.

Image Credit: Micro Sensor Co., Ltd

Gas Pipeline

From extraction to end-users, natural gas undergoes a long transportation pipeline, pressurization, odorization, filtration, pressure adjustment, and transportation. In this process, the temperature and pressure in the pipeline and equipment need to be tracked in real-time to guarantee that the system is operating as it is intended to.

The Company has a lot of experience in tracking gas pipeline temperature and pressure, such as MPM483CNG pressure transmitter, MPM489CNG pressure transmitter, MTM4831 temperature transmitter, MDM7000 intelligent (differential) pressure transmitter, etc.

Such products are specially developed for gas pipeline and equipment monitoring and feature a stable performance with kinds of certificates.

Image Credit: Micro Sensor Co., Ltd

Micro Sensor aims to provide customized products and quantifying solutions for several industrial applications.

This information has been sourced, reviewed and adapted from materials provided by Micro Sensor Co., Ltd.

For more information on this source, please visit Micro Sensor Co., Ltd.