Sponsored by CSEMReviewed by Maria OsipovaFeb 17 2023

The use of electrographic imagery is growing in popularity within the medical industry to enhance surgical assistance and preventive diagnostics. This is achieved through the use of high-density electrodes and the innovative concept of Cooperative Sensors, which results in high-resolution images in a compact form factor.

Moreover, the application of body sensors is becoming widespread in everyday life, sports, and other areas, such as immersive gaming, where they are designed to detect finger movements and eyelid activity.

Usability is a key factor in these applications, presenting challenges such as miniaturization, maintaining signal quality, and the integration of sensors into wearable devices.

To address these challenges, dedicated demonstration electronics have been developed and tested in laboratory settings for electrocardiogram measurements.

Biopotential measurement, which involves the recording of a patient's ECG or EEG, has been a staple in medical practices for many years. However, the traditional method, which involved cumbersome cabling and the use of skin-irritating gel with electrodes, was often unpleasant for patients.

In contrast, the Cooperative Sensors technology developed at CSEM utilizes non-irritating dry electrodes and minimizes the wiring to a simple two-wire bus connection between the sensors.

The same architecture also supports electrical impedance tomography (EIT) and electromyogram (EMG) measurements.

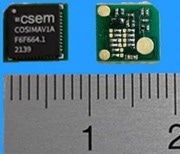

The latest development, known as COSIMA (COoperative Sensors for electrographic IMAging), was created for testing and pre-validation purposes and has already shown promising results. A miniaturization milestone has been achieved with the electronics being housed on a 7 × 7 mm board.

Figure 1. ASIC packaged and mounted on top of a PCB with, on bottom, a few external components and address configuration strips. Image Credit: CSEM

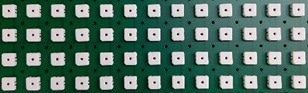

Figure 2. Test board with array of cooperative sensors. Image Credit: CSEM

The integration of all required functions into a single integrated circuit is a crucial step toward reducing the size of the sensor. This integration includes powering, synchronization, communication, and electrode signal acquisition in the same die.

The ExG receiver chain is flexible and can be programmed to use different sampling rates, ranging from 2 kHz to 25 kHz, depending on the maximum number of sensors that can be connected to a single bus.

Additionally, the gain can be adjusted to accommodate the varying input-signal voltage ranges required by EEG, ECG, and EMG applications. EIT stimulation and acquisition are provided by a parallel set of circuits.

The entire system operates with a power budget of 400 µA AC, which is harvested from the square-wave voltage supplied by the two-wire bus. The ASIC prototype was designed using a 180 nm mixed-signal node suitable for the target frequency range and features an area dominated by analog circuitry.

The size of the board is mainly dictated on the top by the selected 48-pin package, which offers the desired test pins, and on the bottom by the many configuration pads which have been implemented.

The ASIC die measures 2.1 × 1.8 mm, and all of the sensor electronics can fit within that surface in a final implementation.

Tests have been performed using an assembly of 15 sensors on a test bench, as shown in Figure 2, and with two sensors applied to a patient, as shown in Figure 3. The board has been designed to accommodate up to 250 sensors.

Figure 3. Experimental test setup on body with two sensors connected on the 2-wire bus. Image Credit: CSEM

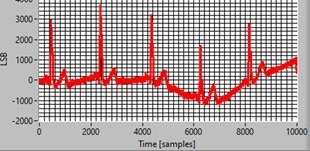

The initial tests on the test bench indicated a noise performance that meets IEC-60601 standards (< 30 µV pp for a bandwidth of 0.05–150 Hz). On the body, the ECG signal is distinguishable but remains noisy due to interference from the 50 Hz mains collected from the laboratory instruments.

Figure 4. Example of recorded ECG from the setup of Figure 3. Image Credit: CSEM

The performed activities have demonstrated the concept and revealed areas for improvement, leading to the development of an updated ASIC in the coming year.

This information has been sourced, reviewed and adapted from materials provided by CSEM.

For more information on this source, please visit CSEM.