In this interview, AZoSensors talks to Dawn Massa Stancavish about advancing underwater sensor technology and imaging.

Can you introduce yourself and provide some background about your company?

I am Dawn Massa Stancavish, the president, CEO, and CINO of Massa Products Corporation. My family’s company history in engineering and sound technology traces back to my grandfather, born into an Italian immigrant family in 1906 in Boston's north end. His journey led him to MIT on a full academic scholarship, where he graduated at the top of his class and became a Swope Fellow with a master's degree.

My grandfather founded our company in 1945 after the war. One of the main philosophies he brought with him was the need to understand mission-specific needs and requirements for sensing technology, develop the sensor to fulfill that, and then work with collaborative partners to make it functional and producible without compromising quality. Over time, we have observed a significant difference between how things work in times of peace versus in areas where there is a need to develop things faster. However, we have always tried to stay involved with both. We have the same engineers trained to understand quality and design, working with acoustics, electronics, software, and production engineering all the way through, as that is how you maintain greater control over a quality product.

Can you talk a little bit about what your capabilities are and how those have changed over the years?

Our structure, and what is important regarding a quality product have stayed the same. Today, we are a third-generation family business, a manufacturer and a government contractor, with women in leadership. Our core capability is always related to sound engineering, whether in the air or water. This has numerous applications, and working with the Navy has always been crucial to us. We supply over 60% of the sonar transducers used in the submarines, Including Columbia-class and the Ohio-class, encompassing both ballistic and fast attack subs. We have been engaged in this for decades, comprehending how sound operates underwater and mastering the production of products that can endure such conditions.

Our capabilities and products also find oceanographic applications. We possess sub-bottom profilers, beacons, and sensors. Our in-air sensors serve collision avoidance, distance sensing, and air sensing purposes. We cover the complete sound spectrum, ranging from the megahertz to the infrasound range. Thus, we operate in air and water across various frequencies and sound pressures. Our commitment to this field enables us to achieve a significant breadth of accomplishments.

We also have a strong commitment to advancing the field and innovating within the technology itself. We have been expanding our patent portfolio, holding over 170 patents, and we continue adding to this number. However, we do not sell or license our technology for royalties. Our primary goal is to create products; our revenue comes from manufacturing.

This approach has enabled us to maintain a strong manufacturing presence, benefiting the community. This was evident throughout the COVID pandemic in Boston (Our location is in South Shore Massachusetts, specifically Hingham). During the pandemic, approximately 50% of small businesses in Boston had to shut down completely. We stayed open and in-person and had zero onsite transmissions as we were an essential business due to our contributions to the Navy. Our ability to act swiftly, unburdened by bureaucracy, played a significant role. Relationships hold immense importance in business and life, and we maintained a wonderful relationship with our partners.

Can you explain some of the workplace issues that you have encountered over the years?

It takes time. Even here, someone does not just start and hit the ground running at a top level. It takes time to learn the nuances of whatever craft you are working on, whether it is on the production line, in machining, in rubber vulcanizing, or even in engineering, because this is a unique technology. It is true of all engineering. It is not a theoretical science; it’s an applied science, so it takes time and some finessing. When that is the reality of what it takes to get acclimated and come into your own in a craft, trade, or profession, and you do not have that mentorship because those people have left due to fear, health reasons, or whatever, it hurts the entire industry on a massive scale.

We were fortunate that we did not have that problem here. We grew, but we did notice it for certain suppliers that we had for certain components. So we had to act quickly to figure out things we could do to mitigate those risks, and some of the ways that we are growing now are also helping with that. However, we grew over the pandemic. We had South Shore Voc Tech visit our facility just a few weeks ago, and we showed them around while discussing our operation. This allowed them to become acquainted with us, as they need to be aware of our presence. Whether they choose to pursue careers as engineers or seek employment right after high school, I want them to recognize this as a viable option. They have the opportunity to engage in exciting projects, such as building sonar for submarines, aiding in whale conservation, or contributing to innovative inventions. We are currently conducting alpha testing for some commercial products that will be co-branded, and their upcoming release is generating a great deal of excitement. Running a successful business involves strategic outreach and community involvement, fostering inspiration and collaboration. Ultimately, it is all about cultivating meaningful relationships.

Can you describe the importance of relationships between your company, your employees, and your clients?

I believe that many people do not give enough merit or understanding to it as it truly deserves. A lot of people think, "Oh, you can't get anywhere. It's all about who you know." But, in reality, you can go out and build those relationships. It is not just about given relationships. It’s about creating and nurturing them.

That is what we have discovered over the last few years, particularly. We have positioned ourselves to build more and more relationships that will help us. It is difficult for anyone to know exactly what is needed if you cannot have the types of conversations that allow you to figure out how to focus your energies. That is the importance of having those relationships because you can have those conversations. In the industry, in your personal life, anywhere – you click with the people that make sense for you, whether it is product development or if it is someone you want to go have lunch with.

Can you elaborate on the overlap between your involvement with the government, specifically the US navy, and your entry into the oceanographic sector?

The overlap is that sound works exceptionally well in water, and today, there are a small amount of companies that have focused solely on this aspect. I mean, there are others, for sure, but we are the only company today that has maintained continuity from the dawn of the industry to the present, and we are still making advancements. So, the breadth of knowledge on how to adapt something is extensive here and accessible, allowing us to accomplish tasks swiftly. Understanding where opportunities lie and meeting those requirements is integral to who we are and what we do.

We have standard off-the-shelf products in the oceanographic space, where you can conduct seafloor mapping and similar tasks. There are products from our history that could be easily modernized and applied to new areas. Spreading awareness of our capabilities is essential to attract new individuals. Designing for specific missions is what we enjoy most because it advances our understanding of our technology and its potential applications; this is how innovation arises.

Regarding existing products, what you see is not all that's available. People sometimes assume that things are fixed in frequency or application, but a slight modification often opens doors to new possibilities. For instance, we are currently collaborating with another company to explore ropeless fishing, an area in which we are partially involved.

We are involved with some things we could do in the littoral zone. The Lobster Robot, which we call Robo Lobster, is an autonomous vehicle that can walk and swim. It can detect mines, but there are other things out there that we are aware of that we could be exploring with different products in similar spaces based on where we are with some of our developments. I think that also ties back to the Navy because when you have something that could be used one way for commercial purposes, it might also be useful for the Navy, the Coast Guard, NOAA, or other organizations that operate in the water.

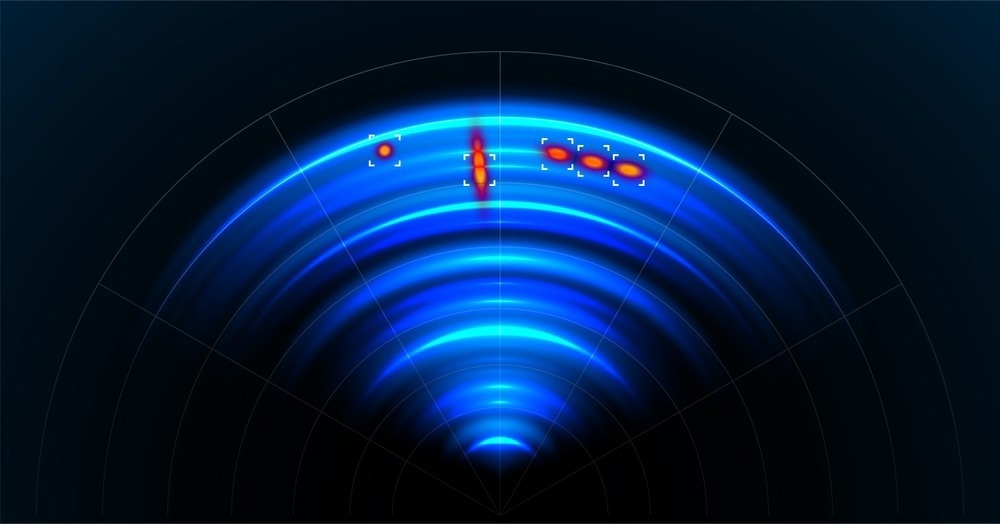

Image Credit: Yuri Hoyda/Shutterstock.com

Could you provide some insights into the artemis project and its significance, considering your current focus on projects and products?

Artemis was a program that emerged a long time ago. Our company was established right after World War II, and that sense of urgency has always been a part of our identity. Artemis debuted around the late fifties to early sixties during that entire endeavor. The first instance it came about was through a request for a quote or price. The objective they aimed to achieve with it was defined at that time as beyond the state of the art.

The Navy hesitated to entrust this to a small company because if a small company were to fail, criticism might follow, questioning the decision to involve a smaller entity. Conversely, if a large company were entrusted with it and could not accomplish it, no shame or blame would be attached. Thus, it was given to a significant company of that era, Bendix. Bendix’s design can be described as small sound squirters. It would pull the sound and the energy through, and its purpose was to shoot the sound out, but it was all in vain. One would 'pop,' and the other would 'pop' when they went out for the field test, resulting in a disaster. The whole thing failed. We knew that design would not work, so we devised a different one. We included it in the proposal and built a prototype we sent simultaneously. We knew what they asked for had never been done, but we knew how to do it. Anyway, the Navy had a large boat powering Artemis with a hole in the center to push it down into the water. When Bendix's design failed, they examined our proposal and prototype and stated, 'This can work.' However, they could not modify those aspects due to the existing rack configuration and powering system. Therefore, they asked if we could redesign it to fit these dimensions. They awarded our first contract for that project, which originated from Columbia University's Hudson Labs. We proceeded to reconfigure the product's physical dimensions, initiated production, and even added an extension to our building, all within a year. During this period, my father was also employed here, so we still have staff who were part of the team.

The whole point is, if something needs to get done and it is essential, we have a sense of urgency to do whatever it takes to meet that challenge with the proper support. Small businesses cannot take it all on themselves, but if you can communicate what you need, you can often get enough to get yourself moving in the right direction.

The shipyards are hiring more people and training them. The Navy has been granted a significant amount of money, which passed through Congress and the Senate, to support this workforce development effort. They are also seeking assistance from smaller companies in the local areas, as we all contribute to outfitting the submarines. The submarine industrial base plays a critical role in our success underwater, and the capabilities of both the submarines and the Navy at sea surpass what many people realize. By building up the workforce, we are helping our country. We are assisting our communities. We are providing jobs to people who possess technical skills and capabilities that might not believe they have a chance otherwise.

The same goes for assemblers or machinists. These jobs are critically needed, which will enhance America's manufacturing. I am truly pleased to be a manufacturer and an engineering firm that can employ all those individuals. I have been engaging with many local schools, aiming to generate more interest in internships for future engineers and offering a place for them to work after high school if they are interested in hands-on work and contributing to outfitting submarines.

These are activities I have been actively involved in over the past year. Thus, Artemis is just a part of that broader story. It reflects who we were then and remains a reflection of who we are now. Numerous companies can do so if there's a need to increase production. However, we are one company located on the South Shore, and our approach aligns with our core capabilities.

Is it true that your company's success over the past 80 years has been attributed to the application of good common sense in engineering?

We began before we were technically known as Massa as a business, but we were founded as Massa in 1945. So, we are approaching 80 years for that milestone. However, if you trace our history back to the days of World War II or even to the introduction of sound in the movie industry, it certainly predates even that. We are all connected on the same journey. We emerged from my grandfather’s teachings as young engineers and future professionals. His stories and lessons are not confined to history textbooks; they are vital to our history and family. All those lessons contribute to our holistic growth, from how to treat people to the importance of keeping your word, staying true to your identity, and focusing on core capabilities.

Unlike many businesses that venture capitalists absorb and experience a decline in quality, that is not who we are. That will never define us. It is an integral aspect of our identity, shaped by my grandfather's teachings, and it is these teachings that have led us to where we are today.

About Dawn Stancavish

Dawn is the President/CEO & Chief Innovation Officer, 3rd Generation at Massa Products Corporation, and holds a seat on the Board of Directors. She is in charge of all Innovation, New Product Development, Marketing & Sales, and she is the liaison between the needs of the industrial/consumer/military world and the technical capabilities of Massa. She is also responsible for preserving and sharing the family values, traditions, and culture at the company. Dawn is a published writer and artist. She holds a master’s degree in psychology from Fairleigh Dickenson University with a focus on Systems Dynamics, has a Certificate in Finance from Harvard Business School, and is a U.S. Patent holder. Additionally, she serves as member of several committees and boards such as: Co-Chair of the “Industrial Base Coalition Committee” for the National Navy Museum Development Foundation, Stellwagen Bank National Marine Sanctuary Advisory Council (SAC) for NOAA, and the Board of Trustees and the Governance Committee for the South Shore Conservatory. She also works closely in partnership with Northeastern University, South Shore Vocational Technical High School, and other schools in the Boston and South Shore of MA to support the development of COOP students, engineers, and “New-Collar” workers.

This information has been sourced, reviewed and adapted from materials provided by Massa Products Corp.

For more information on this source, please visit Massa Products Corp.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.