Experience the future of laser processing technology with Hamamatsu Photonics ́ T-SMILS® Laser Heating system, revolutionizing laser processing through real-time temperature monitoring.

Introducing the T-SMILS Laser Heating System

Hamamatsu’s corporate philosophy emphasizes the advancement of photonics through extensive research and yielding state-of-the-art products. All products are designed to cover the entire optical spectrum and provide various solutions with applications such as analytical, industrial, consumer, and medical instrumentation.

On the other hand, Hamamatsu’s range of laser products is less widely recognized.

This range of semiconductor laser-applied products is suitable for several applications, from R&D to full-scale production.

Hamamatsu has recently introduced the T-SMILS Laser Heating system (L15570 series) – the newest addition to the SPOLD product line.

This is ideally suited to applications requiring critical temperature control. This product represents an upgrade to Hamamatsu’s previous laser heating technology, with a significantly faster sensing regime that enables monitoring as well as the use of temperature instead of power as the primary metric for laser processing.

Product Functionality

The basic function of the T-SMILS system is to heat the materials to be processed with the aid of laser energy, thereby initiating the desired thermal processing.

Diode lasers are used in these products, which typically operate with an output power of 360 W at a wavelength of 940 nm.

The laser diodes are used to generate a wide range of laser outputs. Line optics and spot sizes in the range of 0.1 to 6.4 mm in diameter are available to adapt the properties of the laser if required.

Hamamatsu can optimize the shape of the laser beam and achieve a ‘top hat beam profile’ using a special process. The remaining energy distribution enables optimal and homogeneous heat input to the objects to be processed.

It is the integrated process monitoring that is the notable feature. The T-SMILS can measure absolute temperature, whereas the majority of temperature monitoring systems use relative temperature measurement, allowing the process temperature to be monitored in real time during treatment by the laser. It is therefore possible to control the process to a higher extent compared to laser systems.

Currently, the application focuses for this system include plastics welding, sintering, soldering and curing, with the confidence to provide solutions to the inconsistencies facing the plastics industry for many years.

For example, when two plastics are welded together, the desired strength of the joint can only be achieved if the temperatures are restricted within very narrow limits. Without optimal laser power and/or traversing speed, the desired result will not be achieved. The automatic and continual control of temperature at the melt-point which is provided by this new sensing technology will eliminate variances between plastics welding batches.

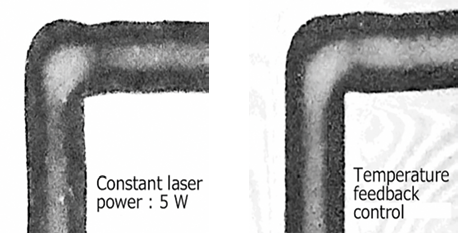

Image Credit: Hamamatsu Photonics Europe

In the left-hand illustration, the impact of temperature feedback control on a laser weld is evident. This microscopic view of a laser weld along a corner illustrates the outcome of employing constant power. This approach leads to irregular laser power distribution, resulting in excessive melting and insufficient melting at various locations. Conversely, the image on the right-hand side demonstrates a uniform weld achieved through the implementation of temperature feedback control.

Comprehensive Service

Hamamatsu uses vast experience to provide a comprehensive service and help to enable users to implement their systems as quickly as possible. Included in this service, Hamamatsu supports customers in the evaluation.

Hamamatsu can advise on the most suitable spot sizes and laser heads for a given application, among other things. This is a highly flexible laser range; with a wide range of options for spot sizes and laser heads they can be tailored precisely to customer requirements.

Product image: T-SMILS Laser Heating System (L15570 series). Image Credit: Hamamatsu Photonics Europe

With integrated real-time temperature monitoring, Hamamatsu provides brand new possibilities in laser processing. As well as providing a wealth of experience and resources at laser laboratories based in Germany and Japan, customers of Hamamatsu gain added value in the evaluation and implementation of their solutions.

This information has been sourced, reviewed and adapted from materials provided by Hamamatsu Photonics Europe.

For more information on this source, please visit Hamamatsu Photonics Europe.