Thermopile detectors are used to measure the temperature of distant objects by converting infrared (IR) radiation into an electrical signal. This primary function finds use across various industries and scientific fields, allowing for precise temperature measurement without direct contact with various materials.

Highly sensitive thermopile sensors also exhibit favorable qualities compared to alternative temperature sensor modules in terms of ruggedness and reliability, making them well-suited for demanding and routine applications.

This article will delve into the operational principles of thermopile detectors and the diverse applications they find in numerous industries.

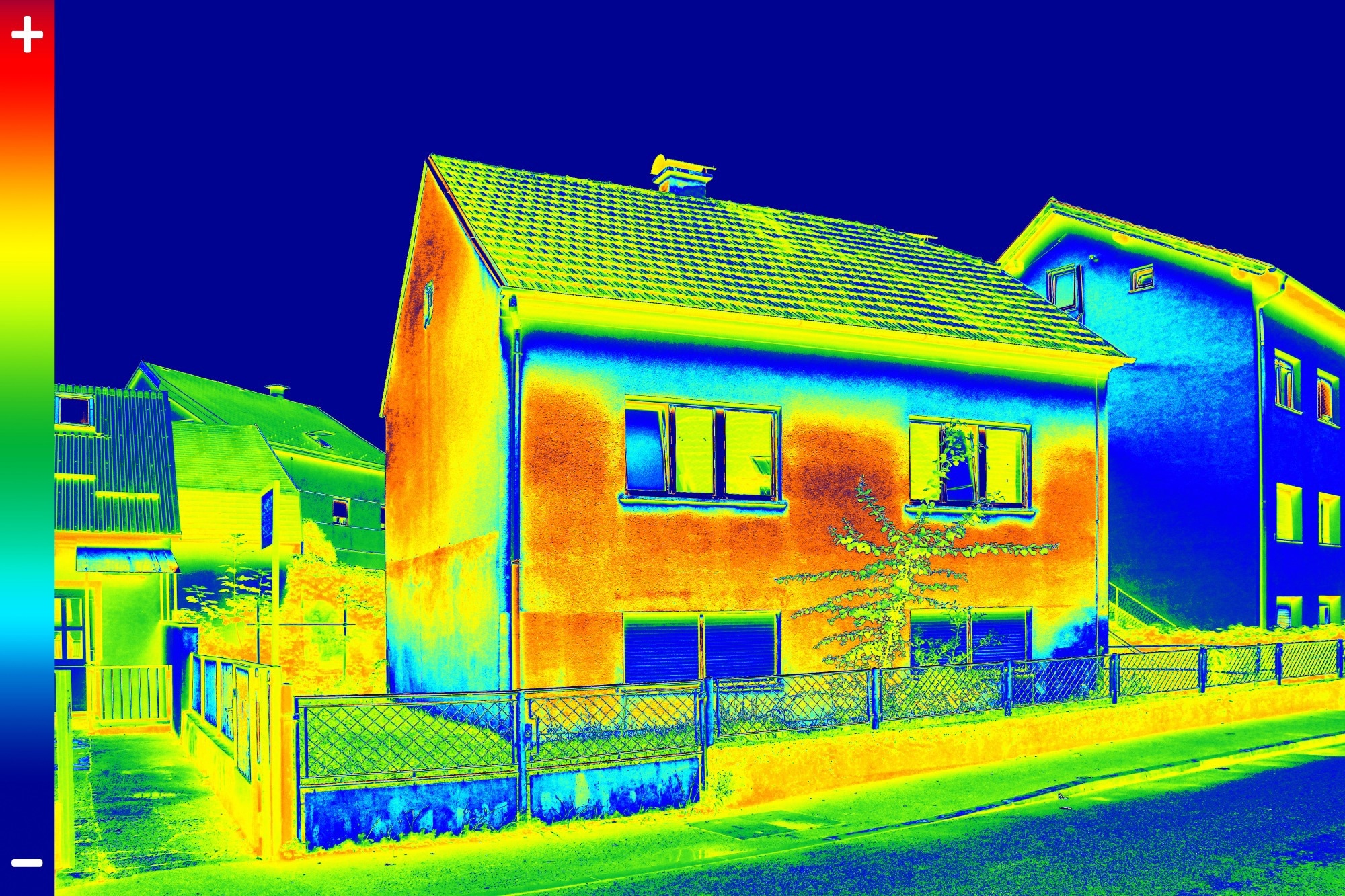

Image Credit: Ivan Smuk/Shutterstock.com

What is the Working Principle of a Thermopile Detector?

Understanding thermopile detectors necessitates a basic comprehension of thermocouple technology. Thermocouples, the most common type of electrical temperature-sensing components, consist of two distinct metal wires joined to form a "hot junction" and a "cold junction."

When the joint is heated or cooled, it generates a subtle voltage (V), also known as the Seebeck voltage, corresponding to temperature changes.

Although there is a proportionality factor to consider, for this article, it suffices to know that the voltage generated is directly linked to temperature differences between the hot and cold junctions.

Thermopile detectors encompass an array of thermocouples interconnected in a series. The fundamental concept is to amplify the impact of each element.

They can be likened to a cluster of miniature thermocouple junctions, similarly separated into hot and cold junctions consisting of alternating n-type and p-type materials, commonly referred to as "arms."

The specific materials used in the arms can vary between different thermopile types. For example, thin film systems often employ antimony and bismuth arms, whereas silicon thermopiles feature alternating n-type and p-type Poly-Silicon or n-type and Gold or Aluminum.

The cold junctions are usually linked to the detector package and positioned around the periphery, while the hot junctions, defining the active area, are situated at the center and coated with an energy absorber.

These hot junctions are suspended on a thin membrane to thermally isolate them from the remainder of the package.

The multiple thermocouples within a thermopile detector are connected in series. This implies that the voltage difference generated by each thermocouple is combined to produce a total voltage output. This total voltage output is directly proportional to the temperature of the measured object.

Given that the Seebeck effect generates a relatively weak signal, thermopile detectors are equipped with voltage amplifiers to ensure the signal's readability by a meter or data acquisition (DAQ) system. Subsequently, a calibration factor or transfer function is applied to convert the signal into a readable temperature measurement.

Applications of Thermopile Detectors

Thermopile detectors have a wide range of applications across various industries due to their precision, stability, and durability. The critical applications of thermopile detectors encompass:

- Energy: Thermopile detectors serve in temperature control for boilers and heating systems, as well as in solar panels to monitor panel temperature, ensuring optimal efficiency.

- Automotive: These detectors find use in temperature sensing for engines, exhaust systems, and catalytic converters, along with temperature monitoring in electric vehicle battery packs.

- Aerospace: In the aerospace sector, thermopile detectors play a role in temperature monitoring for spacecraft and satellites, and they are essential for temperature control in aircraft engines.

- Medical: Within the medical field, thermopile detectors contribute to temperature measurement in equipment like infrared thermometers and enable non-invasive body temperature monitoring, such as fever detection.

- Industrial: Thermopile detectors are integral for temperature control and monitoring in various industrial processes, including drying, baking, and heat treating, as well as in industrial ovens and furnaces.

Looking for Thermopile Detectors?

Dexter Research Center provides infrared sensing solutions for diverse detection needs. To learn more about thermopile detectors, users can refer to the technical papers section on the M5 Thin Film-based thermopile detector product page for a comprehensive introduction to Thermopile Detectors.

This information has been sourced, reviewed and adapted from materials provided by Dexter Research Center, Inc.

For more information on this source, please visit Dexter Research Center, Inc.