The piezoceramic element is the primary component of an ultrasonic transducer. It transforms electrical pulses into sound waves. Once the echoes return, the piezoceramic element transforms the sound waves back into electrical energy.

What Does a Piezoceramic Element Look Like?

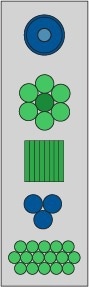

Most of the time, piezoceramic elements are in a disk shape, but they can also come in the form of a ring or bar. A transducer may contain a single element or an array of elements—that is, a sequence of elements linked together.

Image Credit: AIRMAR Technology Corporation

How Are Piezoceramic Elements Made?

When comprised of Lead Zirconate Titanate (PZT) or Barium Titanate (BT), the piezoceramic elements go through numerous processes:

- Pressing: PZT and BT are initially in powdered form, which is then pressed into the desired form.

- Firing: A kiln is then used to bake the pressed shapes. The temperature of the kiln depends on the maximum heat tolerance of the element: the piezoceramic must be fired at precisely the right temperature.

The piezoceramic element is extremely strong but brittle and easily broken or cracked—much like a section of porcelain that has been fired in a kiln. A piezoceramic element that has been moderately chipped or cracked will not function correctly in a transducer.

- Coating: Following pressing, two sides of the piezoceramic element are coated with a layer of silver. It is then baked again to ensure the silver bakes onto the element. This silver acts as the electrode—it conducts electric current through the element.

- Polarizing: The piezoceramic element is then polarized. Piezoceramic elements consist of individual crystals that have a negative (–) and a positive (+) electric charge on their respective ends.

Usually, these crystals rest within the piezoceramic element in a disordered manner. However, if a high-voltage electric field is applied to the piezoceramic element, the crystals reorganize themselves until the majority of them are positioned in straight columns with their negative (–) and positive (+) poles aligned in the same direction.

It is crucial to note that as this process is carried out in an oil bath, it is important that the piezoceramic element has all of the oil carefully removed or material will not bond to it. A weak bond will lead to deficient transducer performance and poor reliability.

How Do Piezoceramic Elements Work?

Transducers take electrical pulses from the power amplifier and transform them into sound waves. This process happens in reverse when the pressure of returning echoes acts upon the transducer.

The internal arrangement of the piezoceramic element’s crystals with their positive (+) and negative (–) poles lying in the same direction is the key factor. The piezoceramic element is activated by pulses of alternating current (AC) from the power amplifier.

The AC changes its direction of flow back and forth [which is why it is said to alternate, and this change in the direction of the flow is noted as (+) and (–)]. When a negative voltage is applied, the piezoceramic elements contract; when a positive voltage is applied, the piezoceramic elements expand. This is because the piezoceramic elements are polarized.

The contraction and expansion of piezoceramic elements convert the electrical pulse into sound waves that propagate until they bounce off an object or gradually weaken and dissipate.

When an echo returns to the transducer, the pressure of the sound waves acts on the piezoceramic element, causing it first to contract and then to expand as each cycle in the echo hits it. This fluctuating pressure on the element generates a small voltage, which is subsequently transmitted back to the transceiver and microprocessor.

The element undergoes expansion and contraction at the frequency of the electrical pulse. This occurs at a rate faster than the human eye can perceive. The frequency of the pulse generator in the power amplifier determines the frequency of the contraction and expansion.

Image Credit: AIRMAR Technology Corporation

How Do Engineers Know Which Piezoceramic Element to Use?

When an electrical voltage is applied to a piezoceramic element, it will vibrate best at a certain frequency. Piezoceramic materials can be thought of as bells. When a bell rings, it produces a tone. Each bell has its own natural resonant frequency. Those who cast bells know the size and shape necessary to create a bell that produces a certain tone.

Much like bells, each piezoceramic material possesses its natural resonant frequencies. The frequency at which a piezoceramic element vibrates best is determined by its shape, thickness, and size. Engineers meticulously control these factors to manufacture transducers that resonate at a frequency aligned with the customers’ needs.

A transducer can be made with a single piezoceramic element that functions at two frequencies. Transducers can house a piezoceramic element capable of efficient vibration at two distinct frequencies.

In thickness mode, the piezoceramic element resonates at one frequency; in radial mode, the piezoceramic element resonates at another frequency across its diameter. A transducer that can operate at two frequencies will have characteristics of both frequencies, such as both shallow and deep water, with good bottom definition.

What is Capacitance?

Capacitance is derived from the word capacity and is the ability of a material to hold an electrical charge. Piezoceramic elements are exceptional capacitors, able to store a large electrical charge. The size of the charge that can be stored is proportional to the size of the piezoceramic element.

Piezoceramic elements can store a charge. All piezoceramics require careful handling, as even minor heating or cooling can generate an electrical charge. Production workers must always short a piezoceramic before handling it. If this is not done, the piezoceramic may discharge, damaging other components in a multi-sensor transducer or even giving the handler a very nasty, albeit harmless, shock.

Despite the necessary precautions when handling piezoceramics, their ability to store an electrical charge can be leveraged as an advantage. Following the soldering of wires and the attachment of a cable, a piezoceramic can be tested with a simple capacitance meter.

A faulty wire connection will appear as a low capacitance reading on the capacitance meter. If the piezoceramic is wired correctly, a much larger capacitance reading will show. This is a simple verification step in the manufacturing process.

This information has been sourced, reviewed and adapted from materials provided by AIRMAR Technology Corporation.

For more information on this source, please visit AIRMAR Technology Corporation.