Sponsored by BinMasterReviewed by Olivia FrostJul 2 2024

Throughout process-driven industries, understanding the bulk density of solid materials is crucial. Bulk density is essential for industries that handle, process, and transport a variety of solid materials efficiently. This article will explore the concept of bulk density, its significance, methods of measurement, and its role in various applications.

Image Credit: Binmaster

What is Bulk Density?

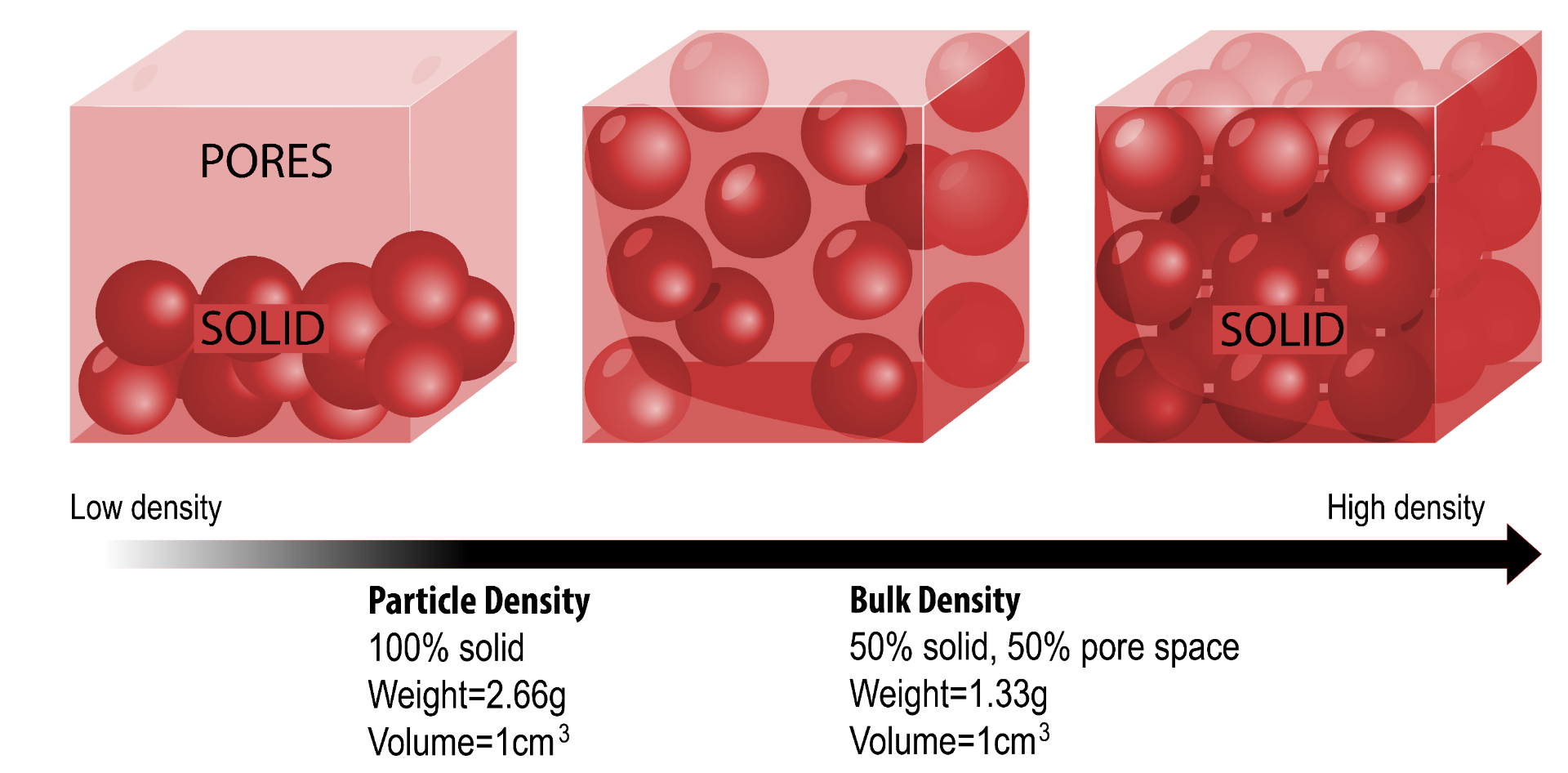

Typically expressed in pounds per cubic foot (lb/ft³) or kilograms per cubic meter (kg/m³), bulk density refers to the mass of a material per unit volume when it is in a bulk state. It is essential to know this property as it helps determine the amount of material that can be accommodated in a given volume.

Why is Bulk Density Important?

Handling and Transportation: Bulk density impacts the behavior of materials when being handled and transported. It also plays a role in material storage. Materials with greater bulk densities require less space, effectively reducing storage and transportation costs.

Processing Efficiency: Understanding bulk density is essential when it comes to designing efficient processing equipment, as it helps determine the appropriate size, capacity, and throughput of the equipment.

Mixing and Blending: In industries such as pharmaceuticals and food processing, bulk density is crucial for accurately mixing and blending ingredients to ensure consistent product quality.

Storage Optimization: Different materials possess varying bulk densities. Optimizing storage based on these bulk densities ensures efficient space utilization and minimizes the storage footprint.

Ways to Measure Bulk Density

Bulk density can be measured using different methods based on the material's characteristics and the desired level of precision. Two commonly used techniques are:

- Direct Measurement: This involves filling a container of known volume with the material and weighing it to determine the mass per unit volume.

- Indirect Measurement: For materials with irregular shapes or porous structures, techniques such as displacement are commonly used.

Factors that Affect Bulk Density

Factors that have an impact on a material’s bulk density include:

- Compaction: External forces or compaction during storage or transportation can lead to an increase in bulk density.

- Particle Size and Shape: Smaller particles and irregular shapes tend to pack more closely together, resulting in higher bulk density.

- Particle Density: Materials with higher particle density generally exhibit higher bulk density.

- Moisture Content: Moisture adds weight to the material, thereby increasing bulk density. However, excessive moisture can lead to compaction, which may reduce bulk density.

Application and Industry Examples

Bulk density plays a pivotal role across a range of industries, such as:

- Mining and Minerals: Determining the density of ores and minerals is essential for efficient extraction and processing.

- Construction: Optimizing the batching of concrete mixtures by controlling the bulk density of aggregates.

- Food and Agriculture: Ensuring consistent product quality by monitoring bulk density in food processing and grain handling.

- Pharmaceuticals: Controlling bulk density in tablet manufacturing to ensure dosage uniformity and proper dissolution rates.

Bulk Density Matters

Understanding material bulk density is crucial for optimizing processes, reducing costs, and ensuring product quality across various industries. By accurately measuring and managing bulk density, businesses can streamline operations, enhance efficiency, and maintain a competitive edge in the market.

For specific bulk density values of various materials, refer to BinMaster’s bulk density chart.

This information has been sourced, reviewed and adapted from materials provided by BinMaster.

For more information on this source, please visit BinMaster.