Bioprocess manufacturing is dependent on precise pressure control. This is particularly important in systems like bioreactors, where even the most minor deviations can adversely impact nutrient transfer and cell growth. These lapses often result in reduced productivity or compromised product quality.

Image Credit: Superior Sensor Technology

Superior Sensor Technology’s range of advanced sensors allows manufacturers to precisely control key bioreactor variables, optimizing production while ensuring compliance with stringent regulations.

These innovations keep processes efficient and reliable, ensuring consistent, high-quality results.

The Critical Role of Pressure Monitoring in Bioprocessing

Pressure control is a cornerstone of many bioreactor systems’ smooth operation and success. These sensors help to efficiently regulate gas flow rates, ensure appropriate media exchange, or manage conditions inside the bioreactor.

Pressure fluctuations can significantly affect cell cultures and the biochemical environment, meaning that high-performance pressure sensors are key to effective real-time monitoring and control.

Image Credit: Superior Sensor Technology

Several pressure sensors from Superior Sensor Technology have been specifically designed for use in bioprocess environments. These sensors offer several key benefits:

- The sensors' high sensitivity allows them to detect minuscule pressure changes. This is key to preventing potential issues such as gas flow imbalances or over-pressurization.

- Rapid response allows pressure deviations to be corrected quickly, ensuring optimal cell growth conditions are consistently maintained.

- The company’s sensors are designed to offer long-term stability and robustness. They can withstand the harsh environments associated with bioprocess manufacturing, including exposure to different biochemicals and frequent sterilization cycles.

Pressure sensors are an essential quality control component in bioprocess monitoring. They ensure the reproducibility and high throughput demanded by current biomanufacturing applications.

Pressure Sensors in Critical Bioprocess Applications

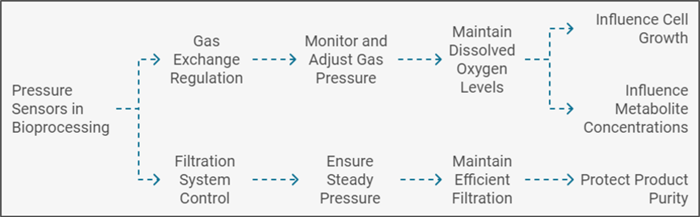

Gas exchange regulation is a particularly critical application of pressure sensors in bioprocessing. For example, dissolved oxygen (DO) levels are closely linked to the pressure of gases (air or oxygen) supplied to the bioreactor.

Precise pressure maintenance is key to delivering the appropriate amount of oxygen at all times, directly impacting cell growth and metabolite concentrations. Pressure sensors from Superior Sensor Technology ensure that gas flow is kept consistent, monitoring and adjusting the pressure in real-time to prevent oxygen deficits or excesses that could potentially impair the bioprocess in question.

Another key application of pressure sensors is controlling pressure within filtration systems. Maintaining steady pressure across filtration membranes protects the purity and integrity of the product by ensuring efficient and dependable sterile filtration of bioreactor contents.

Integration of Pressure Sensors into Process Control Systems

Pressure sensors are also key to comprehensive process control frameworks. They provide real-time data suitable for integration into Supervisory Control and Data Acquisition (SCADA) and Manufacturing Execution Systems (MES).

Feeding pressure data into centralized control platforms like these allows manufacturers to automatically adjust pressure-related parameters, limiting risks associated with human error and enhancing overall system efficiency.

Integrating pressure sensors with process analytical technology (PAT) also enables the implementation of dynamic feedback loops that are able to respond to shifting conditions inside the bioreactor.

For example, should the pressure sensors detect a reduction in air supply pressure, the PAT system will be able to automatically adjust air flow rates to restore optimal conditions. This adaptability is key to minimizing the risk of compromised batch quality.

Pressure Sensors for Compliance and Quality Assurance

Biomanufacturing processes must comply with a wide range of regulatory standards, such as those set by the EMA or FDA.

Pressure sensors remain central to organizations’ ability to adhere to these regulatory requirements, most notably in terms of documenting process integrity and maintaining traceability.

Correctly calibrating pressure sensors ensure their accuracy over time. Superior Sensor Technology’s solutions have been designed to undergo demanding validation protocols, including Installation Qualification (IQ) and Operational Qualification (OQ), affording users supreme confidence in pressure measurements’ accuracy and reliability.

Manufacturers can ensure that their processes remain within the specified parameters by maintaining tight control over pressure levels, ensuring high product quality, and avoiding regulatory non-compliance.

Superior Sensor Technology: Pioneering Precision in Bioprocessing

Superior Sensor Technology offers a diverse portfolio of pioneering pressure sensors specifically designed to accommodate the complexities of bioprocessing.

The company’s sensors provide unparalleled performance in monitoring and controlling pressure, facilitating real-time adjustments that guarantee consistent product quality. Its sensors are robust enough to resist biofouling, withstand the rigors of sterilization cycles, and maintain accuracy over extended periods of use.

Pressure sensors from Superior Sensor Technology can also be seamlessly integrated into existing control systems, offering real-time insight to ensure that bioprocesses run smoothly while adhering to regulatory guidelines.

Superior Sensor Technology's pressure sensors, with their high sensitivity, rapid response times, and long-term stability, are ideally suited to optimizing bioprocess manufacturing and ensuring improved quality control.

Effective, efficient, and reliable pressure monitoring is central to quality control in bioprocessing. Integrating advanced pressure sensors into bioreactor monitoring systems allows manufacturers to maintain precise control over key parameters like dissolved oxygen, gas exchange, and filtration pressure.

Superior Sensor Technology’s portfolio of robust, high-performance sensors consistently delivers the precise, real-time pressure data required to optimize bioprocesses for productivity and quality.

Acknowledgments

Produced from materials originally authored by Superior Sensor Technology.

This information has been sourced, reviewed and adapted from materials provided by Superior Sensor Technology.

For more information on this source, please visit Superior Sensor Technology.