The Gocator® 2490 3D Smart laser line profile sensor available from LMI Technologies has been engineered to scan huge targets in automotive manufacturing, packaging and logistics, and food processing applications.

The Gocator® 2490 sensor features a large measurement range and an ultra-wide field of view to realize an extensive scan area. This allows engineers to carry out comprehensive dimensional gauging and high-resolution 2D/3D quality check of huge targets at inline production speed.

- 2.5 mm XYZ resolution for full dimensional measurement (W×H×D) at conveyor speeds of 2 m/second

- 2 m field of view and large measurement range offer a 1 m × 1 m scan area at 800 Hz

- Incorporated measurement tools and PLC interfaces lead to lower total system cost

High-Resolution 3D Scanning at Production Speed

The 2-megapixel imager enables the Gocator® 2490 to scan and measure 1 m × 1 m packages at resolutions of 2.5 mm and a rate of 800 Hz in X, Y, and Z axes, even at conveyor speeds of 2 m/second, for packaging and logistics applications. Competing systems usually provide a resolution of just 3–5 mm in all three dimensions.

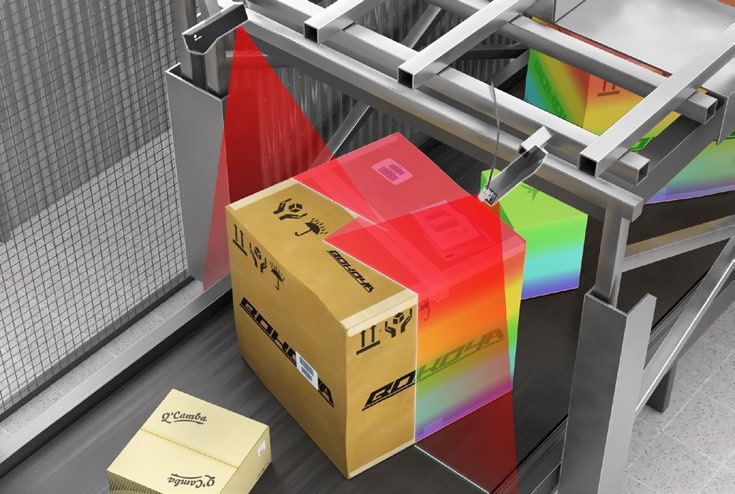

Package volume measurement and sorting. Image credit: LMI Technologies.

Large Scan Area

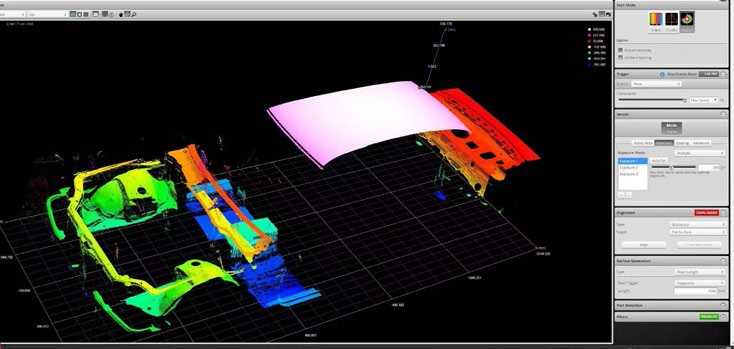

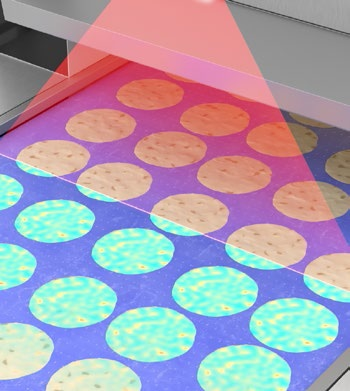

The combination of large measurement range and wide field of view allows engineers to handle a scan area of up to 1 m × 2 m for handling a wide range of huge targets (for example, transverse board scanning and automotive body frame inspection). Thanks to the high Z resolution (for height measurement), the Gocator® 2490 is ideal for applications such as food quality control and optimization.

Single 2490 scan of a car body frame. Image credit: LMI Technologies.

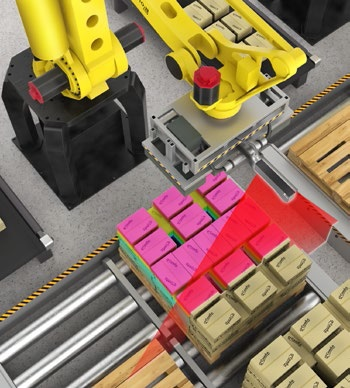

Depalletization. Image credit: LMI Technologies.

Baking quality control. Image credit: LMI Technologies.

Line Confocal Imaging | FocalSpec LMI Technologies

About Line Confocal Imaging Technology | LMI Technologies