The Vibration Signature Analyzer (VSA) offered by MachineSense is an edge-enabled multi-purpose vibration system suitable for both rotating machines and non-rotating machines, and also for vibration monitoring of steel and concrete structures.

The sensor has three main applications—predictive maintenance of both rotating and non-rotating machines (that will need dedicated analytics), tracking impact vibration on structures, like tunnels and bridges, and quality control of products that are impacted by interfering vibration.

The VSA tracks vibration data in both frequency and time domains. The proprietary analytics algorithm of MachineSense monitors and compares the gathered data against a baseline and then establishes the overall health of the machine.

The status of valves, gears, rotors, bearings, and oil is continuously tracked. Apart from allowing users to visualize useful operating metrics, MachineSense can precisely estimate and trigger an alarm about pending machine and component failures. This feature considerably reduces unscheduled downtime caused by equipment.

The sensor can be enabled in event trigger mode for monitoring bridges and other structures. This means that whenever a vehicle is affecting transient vibration, the system will detect vibration solely on impact moments and will examine only the applicable data.

The sensor can be easily fixed to the machine housing through a magnet and continuously quantifies temperature, vibration, magnetic field, and humidity. It is driven by a 24 VDC/110-260 VAC power supply.

The sensor data is sent to a datahub through Bluetooth and (or) SPI, and then transmitted to MachineSense’s local or cloud servers through a router. Datahub can be communicated to a server through LAN or WiFi but if these technologies are unavailable, the optional feature of the GSM/CDMA module can also be utilized.

To reduce network and cloud usage, raw data can be saved in SSD, which can be subsequently accessed through a smartphone app for both visualization and download.

MachineSense’s monitoring solution features the company’s extensive Crystalball™ software that allows users to configure alarms as well as alarm recipients. It offers comprehensive historic data with trend lines relating to the performance of the equipment.

At-a-glance dashboards display the present status of monitored assets by plant or department. Users also receive alerts on actionable maintenance advice which is sent through email or text to remind them about machine maintenance.

Versions

- Sensors: Basic and/or Advanced

- Data acquisition system: Datahub

- Optional features: SSD, GSM/CDMA, and Premise expert system (local server)

Basic

The Basic version is an aggregate of sensors (gyroscope, accelerometer, magnetometer, humidity, and temperature) that can handle up to 250 samples/second. It is linked to datahub through wireless (Bluetooth) communication.

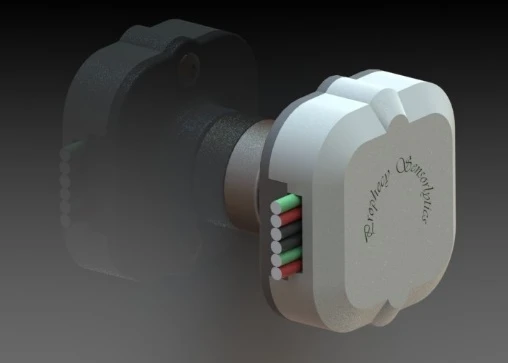

Image Credit: MachineSense

Advanced

The Advanced version is a MEMS-based accelerometer that can send data with a bandwidth of up to 2 kHz across wired connections. It also includes the latest analytic features containing over 100 parameters to monitor and also gain insights into spectrum and raw data analysis.

Image Credit: MachineSense

Datahub

This single-board computer is capable of real-time data acquisition and processing.

SSD

The SSD stores both processed and raw data to save costs relating to cloud and data. It also features a smartphone app to download raw data, synchronize data with the cloud, and visualize machine parameters.

Image Credit: MachineSense

GSM/CDMA Module

The module serves as a substitute for WiFi/LAN in areas that need data to be transmitted to the cloud at regular intervals or in real time.

ON-Premise Cloud

It offers the services of a cloud-based server by running an application that is on the same system as the user application. ON-Premise Cloud is fundamentally a local server with large storage and computation capabilities. It enables users to get all the advantages of the cloud without allowing the data to go out of factory premises, thus ensuring its complete security.

Image Credit: MachineSense

Image Credit: MachineSense

- Basic sensor

- Advanced sensor

- SSD

- MachineSense Datahub

- Cloud-based/local servers

- 4G dongle/router

- Actionable maintenance advice

- MachineSense CrystalBall™ Predictive Software

Features/Specifications of Sensor

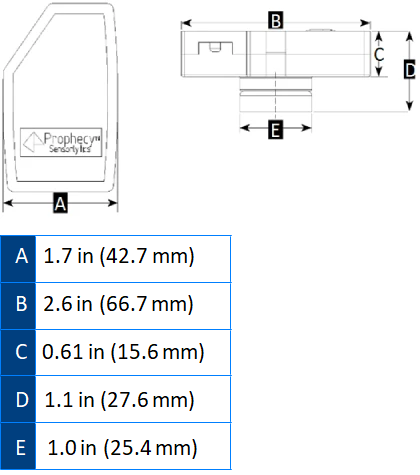

Source: MachineSense

| VIBRATION ANALYZER SENSOR (BASIC) |

| Mechanical |

| Weight |

7.0 oz (0.2 kg) |

| Dimensions length x width x depth |

2.6 in x 1.7 in x 1.1 in (66.7 mm x 42.7 mm x 27.6 mm) |

| Sensor housing material |

Metal plastic hybrid |

| Enclosure rating |

IP64, IP65 optional |

| Environmental |

| Operating temperature |

| Ambient temperature |

14 °F (-10 °C) to 149 °F (65 °C) |

| Surface temperature |

up to 185 °F (85 °C) |

| Hazardous condition |

Class-1 Div-2 |

| Acceleration |

| Range |

- 16 g to + 16 g |

| Resolution |

2% |

| Accuracy |

10 mg |

| Sampling rate (configurable)(/sec) |

40/250 |

| Power |

| Power supply (built in) |

3.3 volt DC adapter |

| Bluetooth Communication |

| Bluetooth Low Energy (BLE)Range |

15 ft |

| Bluetooth Low Energy (BLE)Tx power |

-5.8 dBm |

| Bluetooth Low Energy (BLE)Standard |

4.1 |

| Environmental |

| Operating temperature range |

14 °F (-10 °C) to 149 °F (65 °C) |

| Power |

| Power in |

24 VDC or 110 - 270 VAC |

| Power out |

3.3 volt |

| Bluetooth Communication |

| Bluetooth Low Energy (BLE) Range |

15 ft |

| Bluetooth Low Energy (BLE) Tx Power |

-7.5 dBm |

| Bluetooth Low Energy (BLE) Standard |

4.1 |

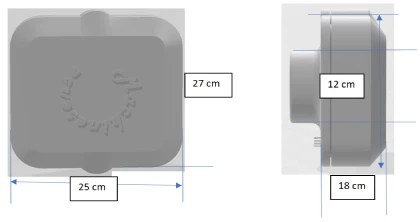

| VIBRATION ANALYZER SENSOR (ADVANCED) |

| Mechanical |

| Weight |

2.5 oz (0.07 kg) |

| Dimensions length x width x depth |

1.06 in x 0.98 in x 0.71 in (27.0 mm x 25.0 mm x 18.0 mm) |

| Sensor housing material |

Metal plastic hybrid |

| Enclosure rating |

IP64, IP65 optional |

| Environmental |

| Operating temperature |

| Ambient temperature |

-40 °F (-40 °C) to 185 °F (85 °C) |

| Surface temperature |

up to 185 °F (85 °C) |

| Hazardous condition |

Class-1 Class-1 Div-2Div-2 |

| Acceleration |

| Range |

- 16 g to + 16 g |

| Resolution |

2% |

| Accuracy |

10 mg |

| Sampling rate (configurable)(/sec) |

Up to 2000 |

| Power |

| Power supply (built in) |

3.3 volt from datahub |

| DATA HUB |

| Functional |

| Connect to sensors via Bluetooth Low Energy (BLE) and SPI |

| Configurable storage data for disconnected applications with optional SSD |

| Communication via Wifi/Lan or optional GSM/CDMA module |

| Smart-phone/tablet-based WiFi connect app (WiFigurator) |

| Local data visualization and download app |

| Auto-upgrade over Internet |

| Mechanical |

| Mounting |

Rail/wall mount |

| Enclosure rating |

IP50 |

| Dimensions length x width x depth |

4.8 in x 3.0 in x 1.3 in (121 mm x 76 mm x 33 mm) |

| Weight |

2.3 oz (0.06 kg) |

| Environmental |

23 °F (-5 °C) to 150 °F (65 °C) |

| Power |

5 volt DC adapter from 110 - 270 VAC |

| ELECTRONICS |

| Processor |

Quad core 1.2 GHz broadcom BCM2837 64-bit CPU |

| Memory |

Micro SD card, SSD (optional) |

| Storage |

16 GB |

| RAM |

1 GB |

| I/O |

40-pin extended GPIO and 4 USB Ports, full size HDMI, LAN |

| Radio |

BCM43438 WiFi and Bluetooth Low Energy (BLE) on board |

| OS |

Linux |

| Certification |

CE/IEC/FCC |

Salient Features

- Acceleration data with a high sampling rate (up to 2 kHz)

- Economical, low investment, and simple to install on prevailing equipment

- Enables both time and frequency domain analysis

- 24/7 health and utility monitoring of machines

- Precise prediction of machine and component failures without unscheduled machine downtime

- Easy-to-interpret maintenance advice is sent through email or text messages and a handheld dashboard

- The option of CDMA/GSM module where LAN/WiFi is unavailable for connectivity

- Option to save raw data locally with SSD, which can be subsequently visualized or downloaded through a smartphone app

- On-Premise Cloud offers all the cloud features without the cloud by containerizing data in a local server inside a factory

- The event trap feature detects irregular events and captures the raw data for additional analysis

Basic sensor hardware design. Image Credit: MachineSense

Advanced sensor hardware design. Image Credit: MachineSense

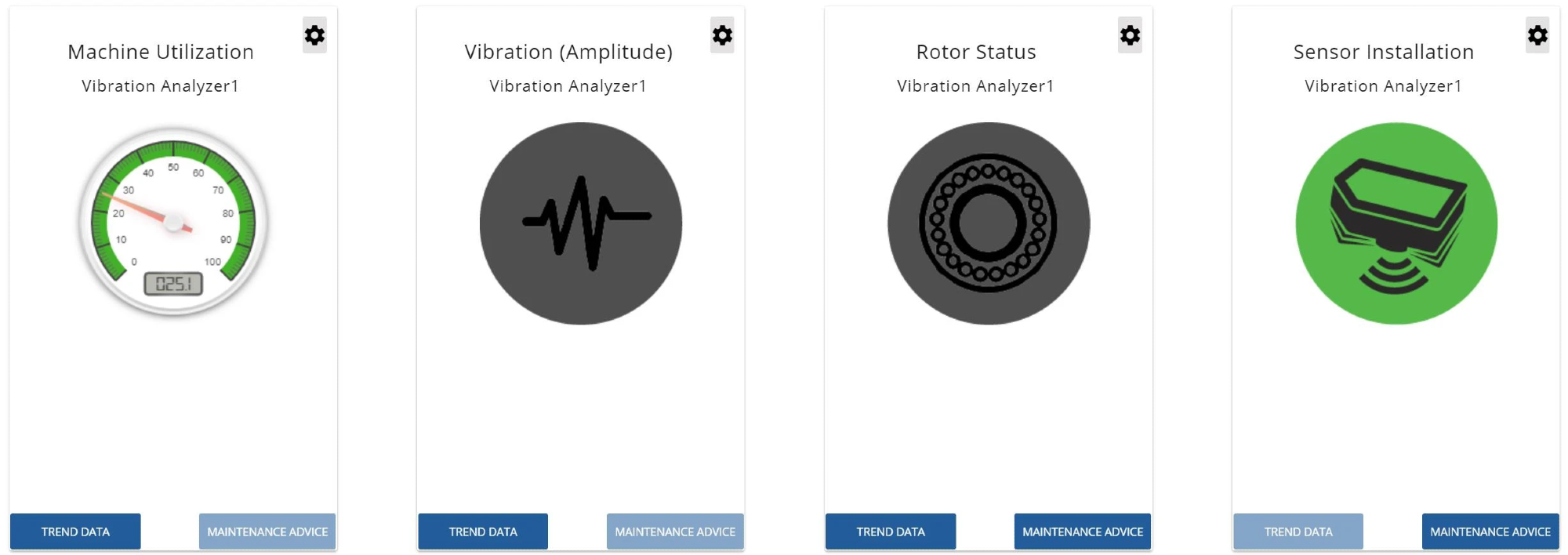

Software and Analytic Visualization

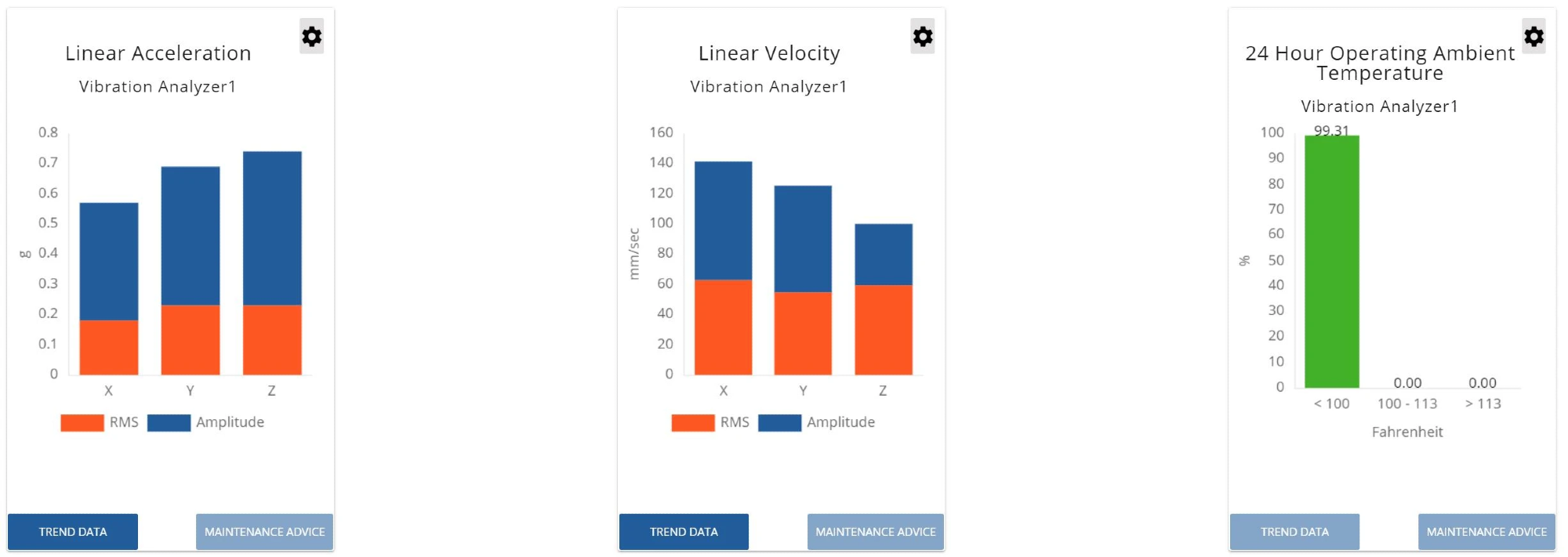

Together with the trends and gauges, the Advanced Vibration analyzer includes expert visualization features for both spectrum and statistical analysis.

Gauges of a machine that shows overall condition of a machine. Comes under both basic and advanced package. Image Credit: MachineSense

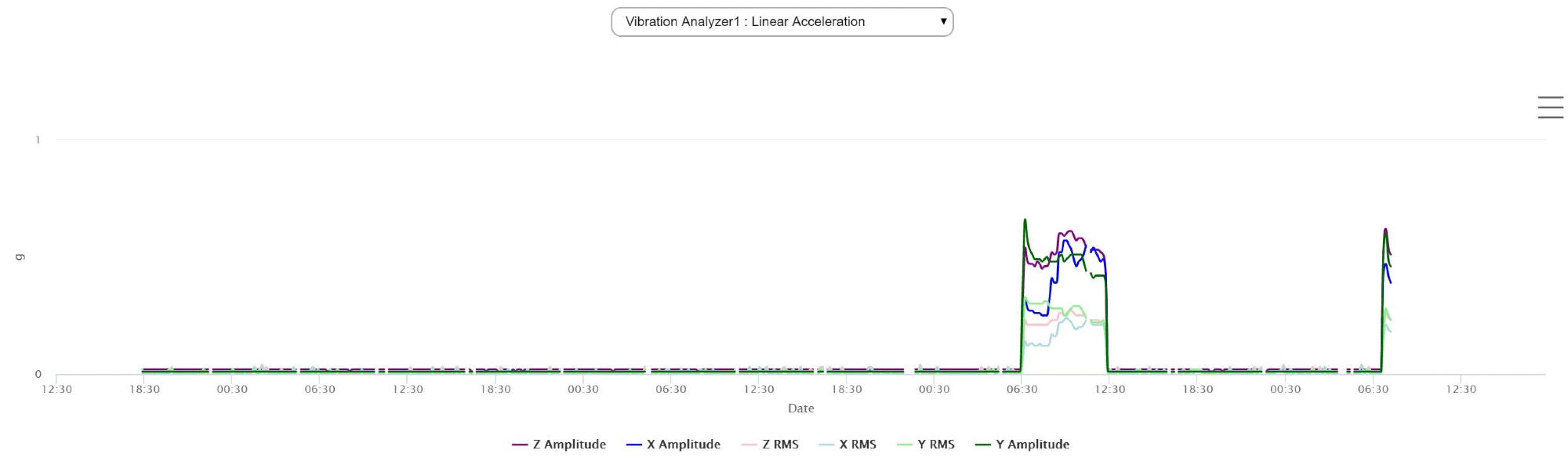

Historical trends of the above gauges. It also comes under both basic and advanced package. Image Credit: MachineSense

Image Credit: MachineSense

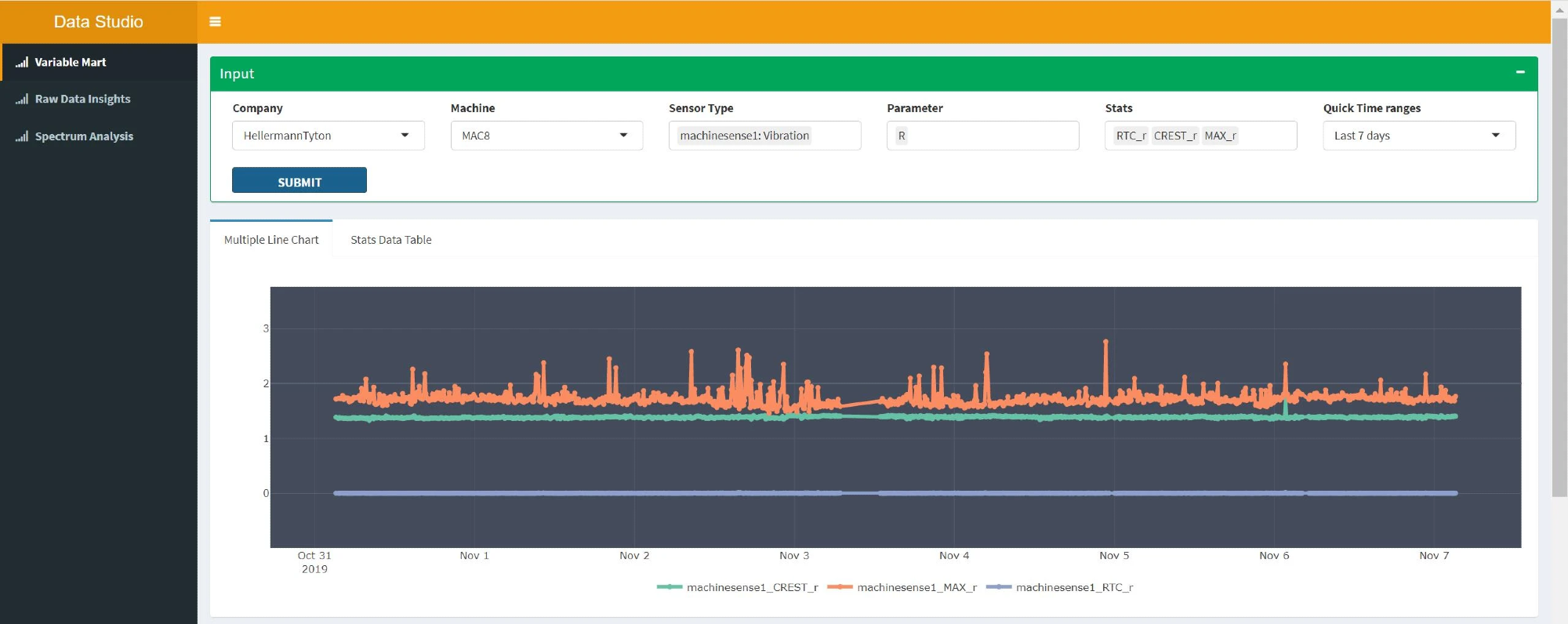

Along with a higher data rate, the advanced vibration analyzer also includes sophisticated analytic features. It enables users to receive more data about the machine and also provides them with options to track the raw data in both time and frequency domains.

The “Variable mart” helps visualize over 100 analytic parameters and also displays their statistics for a configurable time duration based on the storage options. “Raw data insights” offer batch-wise visualization of raw data in varied statistical plots.

In “Event Trap,” all irregular events are recorded under pre-selected parameter/s together with its FFT and raw data. “FFT” offers the amplitude of vibration that is sorted against frequencies. Therefore, it displays the harmonics of the machine, which is an excellent indicator of anomalies.

Image Credit: MachineSense