The surfaceCONTROL 3D 3500 from Micro-Epsilon enables performing high-precision inspection of different surfaces like metals, ceramics and plastics. The system is capable of conducting full-area measurements in just 0.2 seconds through a single snapshot to inspect the geometry, surface and shape.

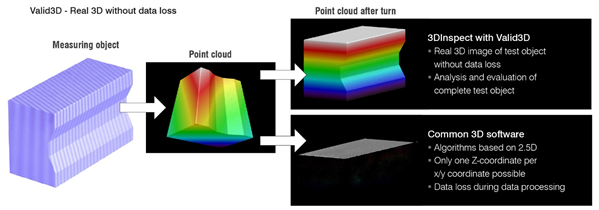

When compared to traditional systems that work with 2.5D, surfaceCONTROL 3d 3500 works on a complete 3D evaluation mode using Micro-Epsilon’s Valid3D technology.

The system exhibits z-axis repeatability of up to 0.4 µm. This helps achieve new standards in 3D measurement technology with even the smallest of height differences or flatness deviations detected effectively.

The newly designed 3D sensor helps perform automated 3D measurements of flatness, coplanarity and hole spacing of precision mechanical parts and electronic components.

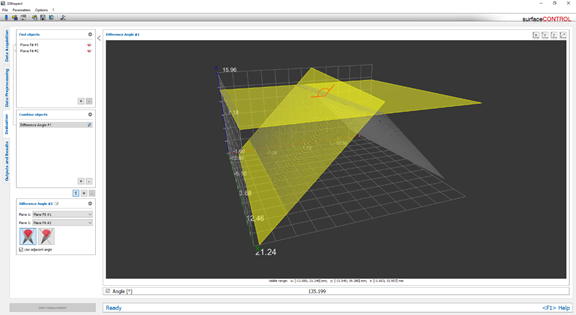

Powerful Software for 3D Measurement Tasks and Inspection

Image Credit: Micro-Epsilon

The surfaceCONTROL 3D 3500 is delivered with the 3DInspect software, which is compatible with all the Micro-Epsilon range of 3D sensors. The latest GenICam standard enables high flexibility and simple integration in the application.

The surfaceCONTROL 3D 3500 functions based on the principle of optical triangulation depending on fringe projection.

A matrix projector provided in the system projects a sequence of patterns onto the surface of the measuring object. The light of the patterns is diffusely reflected by the test object surface, and in turn, recorded with the help of two cameras. The recorded image sequence and the arrangement of both the cameras are used to determine the three-dimensional surface of the test object.

Image Credit: Micro-Epsilon

Key Features

- Micrometer-accurate snapshots with huge measuring fields

- Up to 2.2 million 3D points per second

- Entire 3D images can be obtained in 0.2 seconds

- Highest accuracy of up to <0.4 μm

- Digital interfaces (via 2D/3D Gateway): EtherNet/IP, EtherCAT or PROFINET

- Digital interfaces (integrated): GigE Vision or GenICam

- Digital inputs/outputs: Four digital I/Os for which parameters can be configured (for sensor control, external trigger and output of sensor states)