Spot pyrometers from Fluke Process Instruments have been specifically developed to be flexible and easy to install; durable to resist the hardest tough industrial surroundings; and visual so users can view and comprehend their process temperature data.

Spot pyrometers are a kind of fixed thermal sensor utilized for quantifying a single point on high-temperature surfaces, frequently in huge kilns or furnaces. Such devices tend to measure temperature from the thermal radiation emitted, also called radiometry.

Every pyrometer integrates innovative digital technology along with standard two-wire installations for all setups. Having multiple communication options, such as smart infrared measurement sensors offer the features users need to comprehend their temperature data and control special processes in a small and combined package that is simple to install and function.

The Thermalert 4.0 Series, for instance, consists of several combined infrared temperature sensors with the widest selection of spectral ranges that could be utilized for an extensive range of process control applications.

Every pyrometer conforms to Industry 4.0 standards, integrates innovative digital technology with standard two-wire installations for all setups and could be ordered with IECEx and ATEX certification.

With several communication options, this smart infrared measurement sensor offers the features required by users to comprehend their temperature data and control unique processes in a small, integrated package that is easy to install and operate.

At the same time, the Endurance Series consists of low-temperature and high-temperature two-color pyrometers that satisfy all the needs of modern industry. It is flexible and easy to install; durable to resist the most demanding harsh industrial surroundings; and visual — enabling users to view and comprehend their process temperature data.

The optional camera feature for this sensor enables users to constantly track their process visually, while a LED sighting option enables users to view the spot size on the target to guarantee users have a clean line of sight.

The match function takes the guesswork out of setting the emissivity. Endurance fiber-optic pyrometers enable the measurement of targets that would otherwise be inaccessible due to space constraints or harsh surroundings.

Endurance® High-Temperature Infrared Pyrometers

The Endurance® Series of infrared pyrometers features rough and flexible instruments developed to fulfill the demands of harsh industrial environments and offers constant visual process monitoring in an extensive range of applications and temperatures varying from 50 to 3200 °C (122 to 5692 °F).

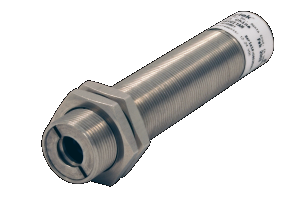

Image Credit: Fluke Process Instruments EMEA

Thermalert 4.0 Series Pyrometers

Each pyrometer adapts to Industry 4.0 standards, integrates innovative digital technology with standard two-wire installations for all setups, and could be ordered with ATEX and IECEx certification. Having multiple communication options, this smart infrared measurement sensor offers the features users need to understand their temperature data and control their unique process in a small, combined package that is easy to install and operate.

Image Credit: Fluke Process Instruments EMEA

Raytek® Compact CI

Small and installable, the Raytek CI noncontact infrared pyrometer quantifies temperatures varying from 0° to 500 °C (32 °F to 932 °F). It comes with accessories for air-purging and cooling.

Image Credit: Fluke Process Instruments EMEA

Raytek® Compact CM

Having temperature ranges from –20 to 500 °C (–4 to 932 °F), the Raytek CM is a tough single-piece system having the flexibility to handle a range of OEM and end-user manufacturing applications.

Image Credit: Fluke Process Instruments EMEA

Raytek® Compact MI3

The Raytek MI3 digital infrared thermometer features a multi-sensor design developed for OEM applications and process control in constant noncontact temperature monitoring from –40 to 1800 °C (–40 to 3272 °F).

Image Credit: Fluke Process Instruments EMEA

Raytek® Compact GP

Raytek GP infrared pyrometers offer process temperature control in hard-to-reach, small or distant targets in a temperature range varying from –18 to 538 °C (0 to 1000 °F).

Image Credit: Fluke Process Instruments EMEA

Raytek Marathon MM

Raytek Marathon MM IR sensor features high-resolution optics, and real-time video monitoring and recording capability for a range of process monitoring application in the temperature range from – 40 to 3000 °C (–40 to 5432 °F).

Image Credit: Fluke Process Instruments EMEA

Raytek® Thermalert® TX Intrinsically Safe Sensor (ATEX)

Raytek Thermalert TX intrinsically safe (ATEX) infrared temperature sensors offer an extensive range of spectral responses for process control applications varying from –18 to 2000 °C (0 to 3630 °F).

Image Credit: Fluke Process Instruments EMEA

Ircon® Modline® 7

The Modline® 7 infrared thermometer has been integrated with Ircon® ModView™ Pro software and a variety of accessories, hence offering remarkable versatility having extended temperature ranges –40 to 2250 ºC (–40 to 4082 ºF), high-resolution optics and quick response times.

Image Credit: Fluke Process Instruments EMEA

Raytek® Raynger® 3i Plus

Raytek Raynger® 3i Plus features the quick and simple transfer of data to a PC or smartphone, a mobile application for rapid data transfer and collaboration and could be utilized as a temporary online thermometer.

This new generation of handheld infrared thermometer has been developed for use in high-temperature industrial applications, 400–3000 °C (752 to 5432 °F), like iron and steel, metal refining, foundry and processing operations, semiconductors, ceramics, chemical, and petrochemical furnaces, as well as heat treatment and power plants.

Image Credit: Fluke Process Instruments EMEA