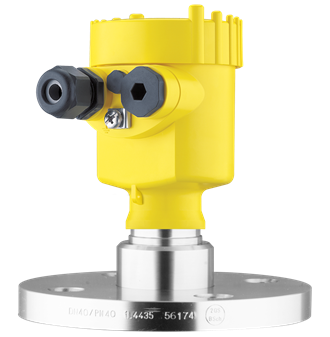

VEGABAR 82 All-Rounder Pressure Transmitter from VEGA is a universally-applicable pressure transmitter. The ceramic measuring cell is resistant to temperature shocks. It can also be integrated with any other VEGABAR Series 80 sensor for electronic differential pressure measurement.

The VEGABAR 82 pressure transmitter can also be used universally for the measurement of vapors, gases, and liquids. Substances such as sand can be handled thanks to the abrasion-resistant ceramic measuring cell easily.

The VEGABAR 82 provides the utmost reliability, and the transmitter can be utilized in all industries. The simple connection of VEGABAR series 80 sensors as electronic differential pressure opens a whole new realm of possibilities for measuring differential pressures.

Image Credit: VEGA Grieshaber KG

Image Credit: VEGA Grieshaber KG

Image Credit: VEGA Grieshaber KG

User Benefits

- Reduced maintenance as a result of the wear-free ceramic measuring cell

- Measurement down to the last drop via the smallest measuring ranges with high precision

- High plant availability through maximum overload and vacuum resistance of the ceramic measuring cell

Application

The Robust, All-Round Pressure Sensor with Ceramic Measuring Cell

The VEGABAR 82 pressure sensor is a strong all-rounder with an inventive flush-mounted ceramic quantifying cell that VEGA manufactures itself as a full-range supplier of pressure instrumentation.

A real highlight is the ceramic pressure sensor that has been resistant to thermal shock. The adaptable standard instrument tackles temperatures ranging up to 150° C. The extremely high overload factor of 200 is unique to the market.

This pressure sensor covers around 80% of all applications in the process industry. With its oil-free ceramic CERTEC® measuring cell, it is fully equipped for use in all areas of the industry:

- Tracking of feed pressure in sewage pipelines

- Overload-resistant level and gauge pressure measurements can be done in pressurized batch vessels

- Tracking of negative pressure in distillation columns (down to absolute vacuum)

- Level measurement of paper pulp level in bleaching towers to safeguard against dry-run damage to the discharge pumps

Other Applications

- Bank filtration: Level and pressure measurement of water from lake and river banks

- Slurry tanks in biogas plants: Point level and pressure measurement in energy production from liquid manure

- Water separator: Level measurement in the water separator and pressure measurement upstream of the vacuum pump

- Storage tank for purified water: Level and pressure measurements given in purified water storage tanks

Technical Specifications

Source: VEGA Grieshaber KG

| . |

. |

| Measuring range – Distance |

- [Meter - Foot] |

| Measuring range – Pressure |

-1 ... 100 bar [Bar - kPa - psi] |

| Process temperature |

-40 ... 150 °C [°C - °F] |

| Process pressure |

-1 ... 100 bar [Bar - kPa - psi] |

| Accuracy |

0.05 % |

| Materials, wetted parts |

- PVDF

- 316 L

- Alloy C22 (2.4602)

- PP

- 1.4057

- 1.4410

- Alloy C276 (2.4819)

- Duplex (1.4462)

- Titanium Grade 2 (3.7035)

|

| Threaded connection |

≥ G½, ≥ ½ NPT |

| Flange connection |

≥ DN15, ≥ ½" |

| Hygenic fittings |

- Clamp ≥ 1" - DIN32676, ISO2852

- Slotted nut ≥ DN25 - DIN 11851

- Hygienic fitting with tension flange DN32

- Hygienic fitting F40 with compression nut

- DRD connection ø 65 mm

- SMS 1145 DN51

- SMS DN38

- Swagelok VCR screwing

- Varivent G125

- Varivent N50-40

- for NEUMO BioControl D50 PN16 / 316 L

|

| Seal material |

|

| Housing material |

- Plastic

- Aluminium

- Stainless steel (precision casting)

- Stainless steel (electropolished)

|

| Protection rating |

- IP66/IP68 (0,2 bar)

- IP66/IP67

- IP66/IP68 (1 bar)

- IP66/IP68 (25 bar)

- IP69K

|

| Output |

- Profibus PA

- Foundation Fieldbus

- 4 … 20 mA

- 4 … 20 mA/HART - two-wire

- Modbus

- Secondary electronics for electronic differential pressure

|

| Ambient temperature |

-40 ... 80 °C |