Micro-Epsilon, a leading producer of sensors in Germany, has advanced an embedded coil technology (ECT), to improve the capacitive displacement devices and eddy current sensing system for enhancing the temperature stability of the sensors.

The ECT will suppress the disadvantages of the previously employed eddy current sensors and permits the designing of the sensors in many shapes.

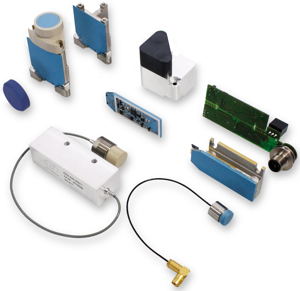

Variety of Sensors manufactured using ECT

Variety of Sensors manufactured using ECT

Micro-Epsilon explains that they have coupled the technology with advanced manufacturing processes to develop numerous creative sensors for operation in temperatures up to a maximum of 350°C, thus protecting it from depleted thermal expansion. The sensors are very powerful and they can overcome shocks and vibrations thus requiring less maintenance.

Chris Jones, managing director, Micro-Epsilon (UK), commented that their company has previously employed the unique technology for the production of modified designs for OEMs and to measure the grinding gap on paper mill refiners. The company can also incorporate electronic components into the sensor heads and can accomplish single as well as multi-sensor channel configuration within a single sensor system.

The electronic elements in the system is integrated in a durable carrier material for supplying greater temperature stability, compared to the traditional capacitive displacement devices and permits the utilization of sensors in 200°C or –269°C temperature ranges.