Mar 15 2016

Scientists at the Universitat Politécnica de València (UPV) and the Universidad Politécnica de Madrid (UPM) have developed a prototype sensor system which not only allows the remote detection of dangerous gases (CO, NO, NO2), but can estimate their concentration levels.

How it works (Source: Universitat Politècnica de València)

How it works (Source: Universitat Politècnica de València)

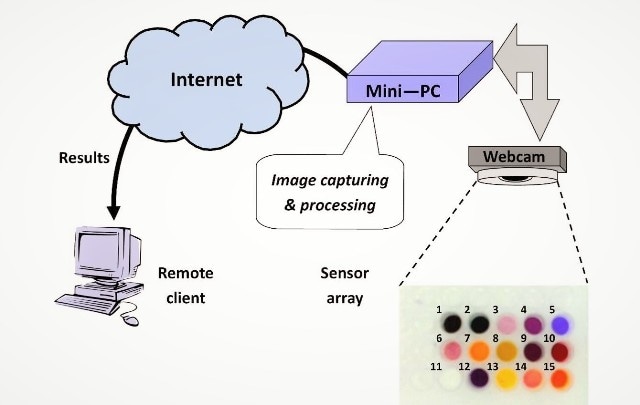

It does so by making detection a visual process, deploying an array of chemical compounds on site that change colour in the presence of certain gases. Images of this array can then be analysed automatically and remotely, and flagged up in the event of pre-programmed colour changes.

Combined with its low cost, it is a good candidate for use in industrial settings where the World Health Organisation recommends maximum hazardous gas thresholds be monitored and observed.

New approach to an old problem

Given the need to ensure the health and safety of employees in industrial settings, various well-established technologies already exist for this purpose. However, three factors have aligned over the past decade to make an alternative, more cost-effective approach possible: the progressive reduction in size and cost of digital cameras; the increasing ubiquity of Internet access; and the miniaturisation of computer devices.

These three elements, plus the selection of the chemical compounds that change colour in the presence of certain gases, underpin the prototype designed by the team at the UPV’s Molecular Recognition and Technological Development interuniversity research institute (IDM).

The sensor system consists, in the first instance, of a tray of 13 different chemical compounds known to change colour in response to atmospheric composition. A minicomputer automatically analyses the photographs taken by a webcam, looking specifically for certain colour changes. The results of the analysis are sent to a remote computer using standard Internet protocols.

The use of non-specialised equipment, such as webcams and minicomputers, and standard communications protocols not only means that this solution is low-cost, but also fully integrable with other control systems. It can also be easily applied to other contexts, such as the evaluation of the quality of foodstuffs wrapped in plastic packaging.

First tests

Early tests confirm that the system works efficiently for the detection of carbon monoxide (CO), and both nitrogen monoxide and dioxide (NO, NO2), and can even estimate the concentration levels of these gases in the test environment. This latter is of particular importance in order to ensure observance of maximum gas thresholds as recommended by WHO.

Research was led by UPV professors Ramón Martínez Máñez and Eduardo García Breijo, in collaboration with professor Rubén Fraile Muñoz of the UPM’s School of Telecommunications Systems and Engineering (EUITT).