By installing a number of fully integrated online measurement systems from Micro-Epsilon in various stages of its tyre production process, a UK-based tyre manufacturer has seen dramatic improvements in process capability and tyre quality.

The plant, which produces tyres for the SUV performance market, operates continuously around the clock 350 days per year, producing thousands of tyres on average per day.

The plant is a mixture of manual processes and automated machinery, with different machines responsible for producing the various components of a tyre, such as the sidewalls, treads, beads, shoulders and inner liners.

Since early 2015, the plant has installed a number of online tyre measurement systems from Micro-Epsilon in various stages of its tyre production process. These measurement systems are fully integrated into the production processes, inspecting the various tyre components as they are manufactured.

This is crucial as it enables the plant to compare the actual tyre components being produced with the original design.

Over time, this means the plant has been able to improve its understanding of the behaviour of the process variables such as line speeds, temperatures, pressures, etc. and the effects of changing these on the quality of the products produced.

Process capability has improved significantly since installing the measurement systems, which have proven themselves to be 99.9 per cent reliable.

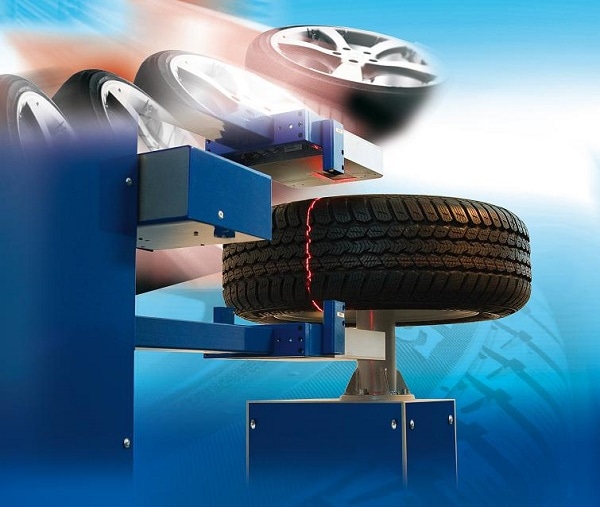

The thicknessCONTROL.TTP profilometer system from Micro-Epsilon is fully integrated into the process and requires no manual intervention. The O-frame configuration system measures the complete profile of tyre sidewalls after they are dual extruded.

The measurement system incorporates two directly opposed optoNCDT 2300 laser triangulation sensors. Each sensor traverses across the top and bottom surface of each extrusion with the software displaying the resulting thickness profile of each extrusion.

The plant takes six key measurements across each profile (12 in total) of sidewall features, including thickness, width and area. The results are then compared to the stored design.

No operators are involved. The line knows what’s being produced and the inline profilometer system helps to verify the profile dimensions of what is being produced and whether these match the design drawing.

The plant has a complete visual profile of a sidewall which means that it can modify the design of the tools and dies if necessary, to reduce tool wear or to improve process quality.

Prior to installing the online profilometer system from Micro-Epsilon, the plant used an offline profilometer, whereby random samples were periodically removed from the process and inspected.

However, this method of inspection didn’t truly reflect the process itself. Rubber is not a stable material: it stretches and shrinks if temperatures and pressures change. Because of this, the plant could never hear the voice of the process, just a snapshot in time.

Prior to installing the Micro-Epsilon systems, the plant was reliant on offline measurement equipment, which were not always reliable. Now, the plant can perform real SPC [Statistical Process Control], not just snapshots from samples taken off the line.

Real process variability can now be seen, which has also revealed how operators can change the process variables to improve product quality, as well as the quality of the tooling.

As well as supplying and installing the turnkey measurement systems, Micro-Epsilon also provides an Internet-based remote access support service for the plant. If any software modifications for the measurement systems are required, these can be updated remotely and the system tuned to meet the needs of the plant.

For more information, please call the sales department on 0151 355 6070 or mailto:[email protected]