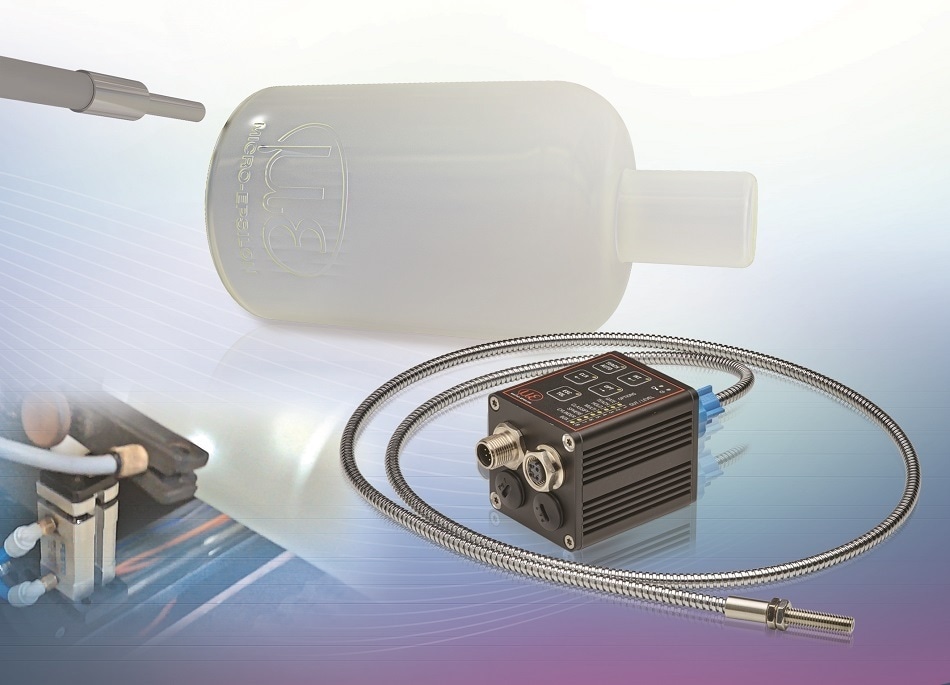

The colorSENSOR CFO100 is used for precise position detection in automated printing processes of cosmetics bottles. The semi-transparent glass ceramic bottles are embossed before they are printed. Due to the indentation, there is a minimal color difference at the embossing point. The colorSENSOR from Micro-Epsilon detects this deviation and therefore the exact position for the print is determined.

Color sensors from Micro-Epsilon are not just designed for high precision color measurement. These sensors can also be used to implement detection, testing or positioning tasks. The company David Blankenaufulland uses color sensors from Micro-Epsilon for precisely these purposes. The company develops and manufactures CNC screen-printing machines for printing on a variety of containers made from plastics, textiles, ceramics or glass.

When automatically printing on semi-transparent glass ceramic bottles, it is necessary to determine the exact position for the printing. Therefore, a reference mark is embossed into the bottles. Due to the depression of the embossment, the color of the reference mark deviates slightly from the rest of the bottle surface. The colorSENSOR CFO100 detects this minimal color difference, which enables the exact determination of the printing position below the embossment.

The colorSENSOR shows clear advantages over other measuring methods. First, it masters the semi-transparent surface. Second, it is ideally suited to this kind of position measurement task due to its favorable price/performance ratio. For this measurement task, the colorSENSOR CFO100 is integrated into the machine and so is the optimum solution for an efficient printing process.

Thanks to its high speed measurement frequency, it outputs a complete OK / NOK signal within the specified cycle time of less than two seconds. Its small measurement spot size with a diameter of just 0.6 mm ensures reliable and precise embossment detection. Due to the spatial separation of measuring point and signal processing, the sensor withstands the typical ambient conditions such as dirt and temperature inside the machine. The compact and robust controller can be easily and quickly integrated into the back of the machine, while the space-saving fiber optics with ferrule can be positioned at the measuring point.