Tekscan, Inc., is pleased to introduce PM64™, a new customizable pressure mapping scanning electronics module with an incremental pricing model that supports a large-scale deployment for high-volume users and original equipment manufacturers (OEMs).

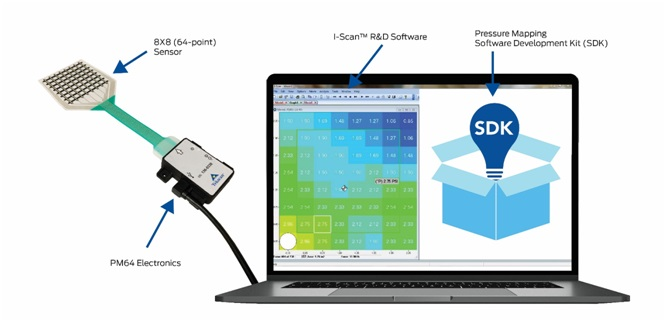

PM64 Starter Kit Components

PM64 Starter Kit Components

Tekscan is a manufacturer of pressure mapping technology, a tool used by engineers, field service technicians, and OEMs, to measure interface pressure between nearly any two mating surfaces. Each pressure mapping system consists of an ultra-thin pressure sensor, scanning electronics, and a robust analysis software to help engineers analyze pressure distribution in real-time. Pressure mapping technology is most often used in R&D to help verify finite element analysis models, or make adjustments in machine tooling to improve production processes.

Now with PM64, companies that see the value of pressure mapping technology have a viable solution to implement their application at a larger scale within a single operation, or across multiple locations.

“PM64 answers a market need for companies that understand the benefits of pressure mapping technology, but for budgetary reasons, have never been able to implement their application at a large scale,” says Camilo Aladro, Product Manager for Tekscan’s Pressure Mapping Division. “We’ve developed PM64 as a basic configuration for customers to develop their own custom pressure mapping application, and cost-effectively deploy that application to their desired scale through an incremental pricing model."

As Aladro explains, this process begins by purchasing the PM64 Starter Kit. The Starter Kit includes an 8x8 (64-point) sensor, PM64 electronics, Tekscan’s R&D Software (I-Scan™), and the Pressure Mapping Software Development Kit (SDK). Utilizing PM64 with the SDK – an easy-to-use software Application Programming Interface (API) – the end user can include pressure mapping data in a live feedback loop for inline Quality Assurance/Quality Control testing. From there, companies can deploy their custom pressure mapping application throughout their company, and save on their bottom line with the more systems they purchase.

“The SDK gives programmers everything they need to develop their own custom PM64 software application to acquire, record, and read pressure mapping data in a .NET framework,” says Aladro. “PM64 makes it easier and more affordable for companies to equip their service technicians with an actionable tool to align machines with greater efficiency, and machine builders to offer a value-added feature to gain a competitive edge with their machine design.”

Along with high-volume users and OEMs, PM64 is a viable solution for test & measurement applications where pressure testing is taking place across multiple locations or longer time durations.