CO2, SO2, H2S, C2H6O, CH3OH and O2 gas measurement in beverage bottling plants, breweries, wineries, dispensing plants and CO2 extinguishing systems for warehouses.

Carbon dioxide (CO2) is highly relevant in the beverage industry. Soft drinks and beer are perceived as particularly sparkling and refreshing due to "carbonic acid". In still beverages, carbonic acid improves the shelf life. But carbon dioxide is also indispensable for wine and sparkling wine production to keep oxygen away from the vines.

Copyright MSR-Electronic, Deutschland, Beverage plant

In some drinks, CO2 is produced by fermentation (beer, sparkling wine), in others it is added artificially (lemonade, soda water). During production, carbon dioxide is pumped into the beverage under high pressure, where about 0.2 % of it reacts with water to form carbonic acid.

In beverage production as well as in beverage bottling, various gases are used that have to be detected around the clock. MSR-Electronic offers reliable gas sensors, controllers and warning devices to protect people and equipment from toxic and combustible gases.

CO2 is also an important gas for winemakers. In order to keep the oxygen away from the wine so that the drink retains its taste and colour, as well as for blanketing of wine, winemakers usually use N2 or a mixture of N2 and CO2. In this case, the oxygen content is monitored by gas sensors.

H2S can be the cause of odour problems in the food and beverage industry, for example. Most areas of the food industry generate wastewater that is highly contaminated with biodegradable organic substances. Odours caused by wastewater are one of the many current environmental problems associated with the food and beverage industry. The odour nuisance may be related to the release of hydrogen sulphide (H₂S).

MSR-Electronic offers various gas monitoring solutions for the beverage industry.

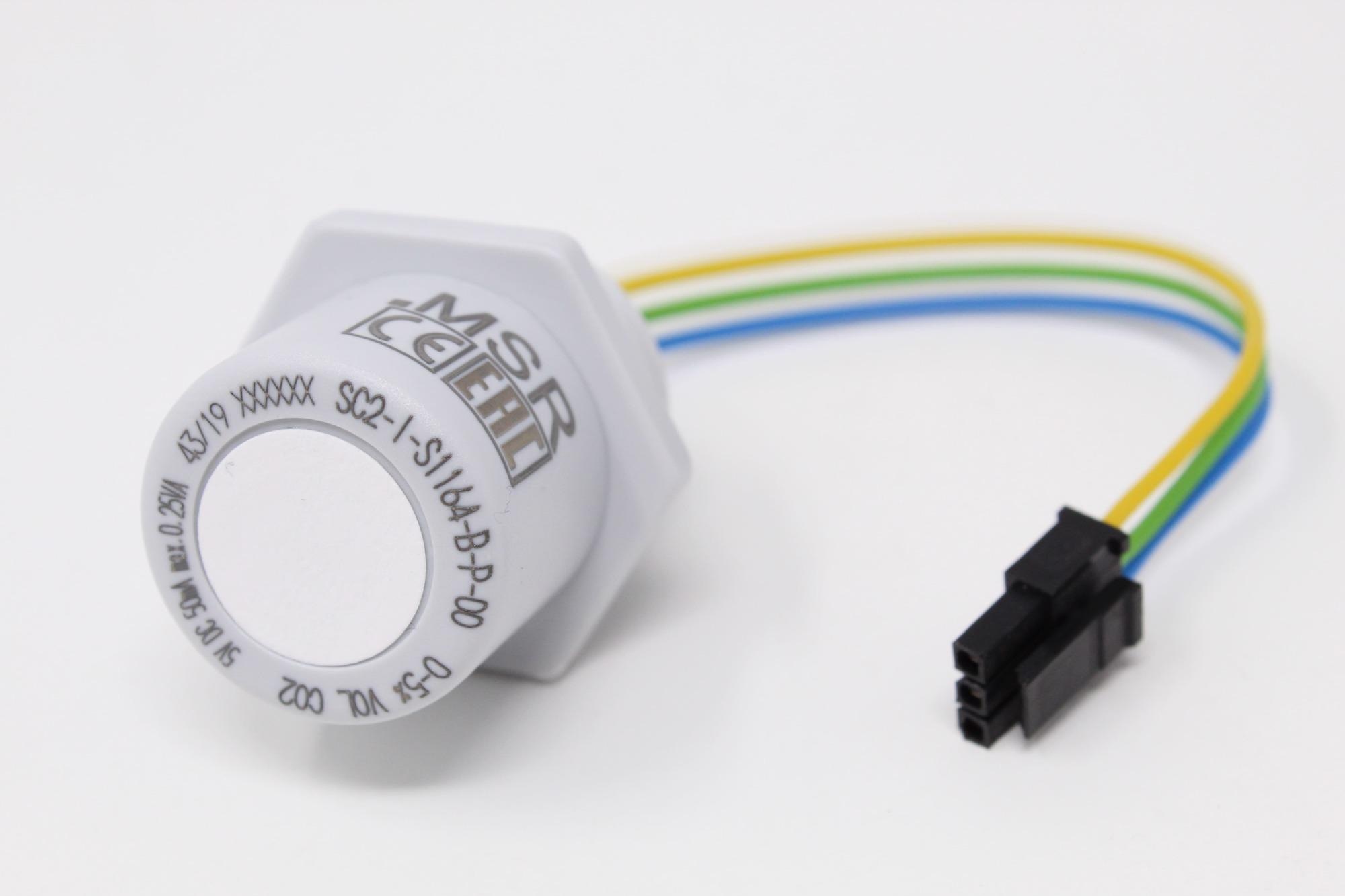

Copyright MSR-Electronic GmbH, Deutschland, SC2 Gas Sensors

MSR develops individual gas sensors and gas warning systems that can detect toxic or combustible gas concentrations. In addition to the sensor element and the measuring amplifier, the gas sensors also contain a controller for processing the measured values. Thus, various data can be processed and evaluated, such as the temperature for compensating the measured value. Calibration intervals and errors are also monitored and transmitted to the evaluation device.

Thanks to the X-Change technology, calibration can be carried out by simply exchanging the sensor head or by using the integrated, convenient calibration routine directly on the system. The gas sensors are designed for connection to the MSR controllers and boards. The DGC-06 Controller, for example, is suitable for large systems and manages up to 128 gas sensors, the Compactcontroller up to 10 gas sensors, and the MSC2 Controller up to 3 gas sensors.

The control centre: the DGC-06 Gas-Controller

Copyright MSR-Electronic GmbH, Deutschland, DGC-06 Gas-Controller

The Controller is used for the monitoring and warning of toxic and combustible gases and vapours as well as of Freon refrigerants within a wide range of the gas measurement technique. Numerous adjustable parameters and set-points permit individual adaptation to many applications.

The DGC-06 Gas-Controller also fulfils the functions of CO monitoring in garages, tunnels and go-kart tracks and is compliant with the current EN 50545-1.

Further information on MSR products can be found here in the current MSR-Electronic online catalog or in the webshop: www.msr-24.com.

MSR-Electronic is a manufacturer of fixed gas warning systems with decades of experience in the field of building automation and gas measurement technology. The international company with headquarters in Germany has a wide range of methods for the detection of toxic and combustible gases. On this basis MSR-Electronic develops individual gas sensors, controllers and warning devices for many applications, such as parking garages, tunnels, petrochemical industry or shipping. The products meet more than the general standards and regulations and can therefore guarantee the safety of the plant. www.msr-electronic.de/en