Packaging is essential. Nevertheless, it is important to choose a type of packaging that minimises environmental impact.

Image Credit: imago, Jochen Tack, Packaging;

Modified atmosphere packaging (MAP) is a technology for keeping food fresh. It involves replacing the natural ambient air in the packaging with a gas or gas mixture, often nitrogen and carbon dioxide.

This procedure ensures the quality of fresh produce over a longer period of time and at the same time extends shelf life in supermarkets. A wide range of products is gas flushed; some typical products are e.g. fresh meat, coffee, ready meals, fruit & vegetables.

Packaging under a protective atmosphere using the example of a potato chips bag: The manufacturer does not blow up the bags to make them look bigger, but to protect the food inside by the volume buffer and to make them last longer. To do this, they don't use "normal" air like we find all around us. This would not keep the food fresh because there is also oxygen in it, which makes the fat contained in it rancid. For a longer shelf life, pure nitrogen is used here.

Depending on the food, other gases are used for protection. For example, carbon dioxide is pumped into the bag of cut lettuce to prevent it from rotting, or oxygen is added to meat to keep it nice and pink.

In MAP technology, the normal air is first sucked out of the product packaging in a sterile environment and a so-called protective gas (e.g. O2 CO2, N2, CO, Ar, H2, He) is filled in instead.

Gas sensors and controllers from MSR-Electronic provide reliable protection against gas leakage in the packaging industry.

MSR-Electronic solution for monitoring gases and gas mixtures

When packaging under modified atmosphere, it is crucial to ensure correct gas mixing as well as leak-free packaging. For most products, it is also important to set limits for the maximum and minimum residual oxygen content in the packages.

For targeted gas monitoring, MSR-Electronic offers individual gas sensors and gas warning systems that detect toxic or combustible gas concentrations.

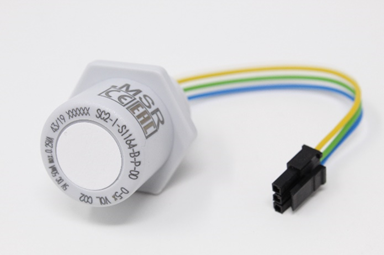

Image Credit: MSR-Electronic GmbH, Germany, SC2 Gas Sensor

In addition to the sensor element (el.ch., pellistor, semiconductor or infrared) and the measuring amplifier, the SC2 gas sensor contains a μController for processing the measured values. All relevant data and measured values of the sensor element are stored in the μController in a fail-safe manner and are transmitted digitally to the board via the local bus. The calibration management is also integrated in the μController of the gas sensor.

Thanks to the X-Change technology, calibration can be carried out by simply exchanging the sensor head or by using the integrated, convenient calibration routine directly on the system. The gas sensors are designed for connection to the MSR Controllers and Boards. The DGC-06 Controller, for example, is suitable for large systems and manages up to 128 gas sensors, the Compact controller up to 10 gas sensors and the MSC2 Controller up to 3 gas sensors.

The Control Centre: The DGC-06 Gas-Controller

The Controller is used for the monitoring and warning of toxic and combustible gases and vapours as well as of Freon refrigerants within a wide range of the gas measurement technique. Numerous adjustable parameters and set-points permit individual adaptation to many applications.

Image Credit: MSR-Electronic GmbH, Germany, DGC-06 Gas-Controller

The DGC-06 Gas-Controller also fulfils the functions of CO monitoring in garages, tunnels and go-kart tracks and is compliant with the current EN 50545-1.

Further information on MSR Products can be found here in the current MSR-Electronic online catalog or in the webshop: www.msr-24.com.

MSR-Electronic is a manufacturer of fixed gas warning systems with decades of experience in the field of building automation and gas measurement technology. The international company with headquarters in Germany has a wide range of methods for the detection of toxic and combustible gases. On this basis MSR-Electronic develops individual gas sensors, controllers and warning devices for many applications, such as parking garages, tunnels, petrochemical industry or shipping. The products meet more than the general standards and regulations and can therefore guarantee the safety of the plant. www.msr-electronic.de/en/