Dimensionics, a supplier of measuring and testing technology, has chosen 2D/3D laser profile scanners from Micro-Epsilon for use on its Disionic Sheet Control measuring table, a fully automatic system for testing the dimensional accuracy of sheet metal.

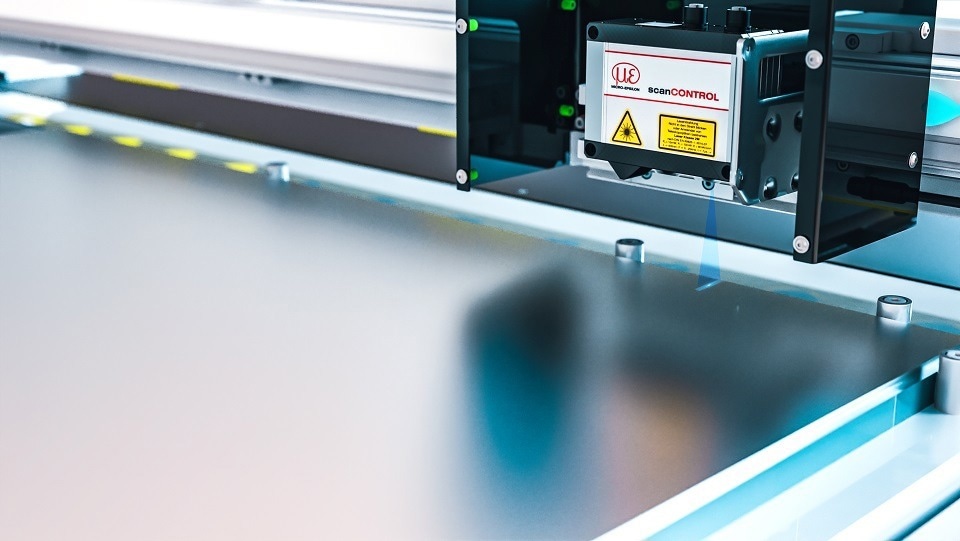

The measuring table is equipped with two scanCONTROL 3000-25/BL laser profile scanners. Image Credit: Micro-Epsilon

The measuring table is equipped with two scanCONTROL 3000-25/BL laser profile scanners. Image Credit: Micro-Epsilon

The Disionic Sheet Control measuring table is equipped with two scanCONTROL 3000-25/BL laser profile scanners from Micro-Epsilon. The scanners, which have a compact design with integral controller, measure sheet metal blanks and check these for width, length, angle, straightness, deflection (convex/concave) and the planarity of the sheet metal edges.

Blue Laser Technology

The two laser profile scanners are mounted on the XY table. Each scanner has a measuring range of 25 mm and is guided over two edges in the X and Y direction of the sheets. The sensors use Blue Laser technology to ensures they achieve maximum precision and reliable results on demanding surfaces such as shiny metallic sheet.

Measurement and data output for the entire test process take just a few seconds. The laser profile scanners transmit the measurement data via Gigabit Ethernet to the extensive system software for analysis. Based on the data, any production errors such as inaccurate edges or dimensional deviations due to inaccurate positioning can be detected. As a result, the production quality of the sheet metal blanks is checked in a traceable and reliable manner. In this way, the laser profile scanners, together with the Disionic Sheet Control measuring table, ensure an automated testing process that was previously a laborious manual process.

Mathias Evers, Application Engineer at Dimensionics comments: “Both the versatility and reliable operation of the Micro-Epsilon sensors are impressive. We have already been won over by the product quality in numerous projects and will also count on Micro-Epsilon in future tasks.”

The scanCONTROL 30x0 series is among the highest performing profile sensors in terms of their size, accuracy and measuring rate. They provide calibrated 2D profile data with up to 7.37 million points per second. A profile frequency of up to 10kHz enables precise profile measurements in dynamic high speed processes. The high resolution sensor matrix offers a resolution of 2,048 points with an ultimate point distance of just 12µm, enabling extremely fine details to be detected reliably. The sensors are available with either blue or red laser diodes.