Gas sensors from MSR-Electronic monitor gas concentrations during tunnel construction and regular traffic.

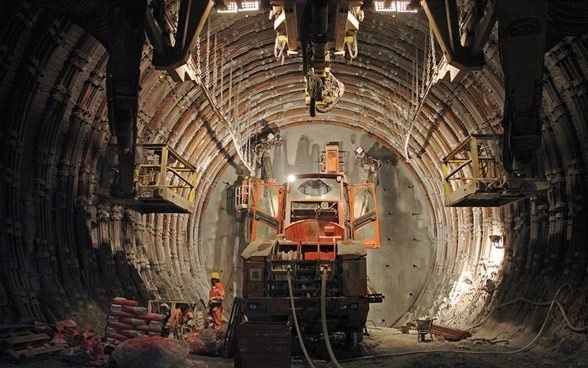

Construction Work in the Gotthard Base Tunnel. Image Credit: © AlpTransit Gotthard AG

Construction Work in the Gotthard Base Tunnel. Image Credit: © AlpTransit Gotthard AG

In addition to parking garages and parking halls, road tunnels, too, are subject to the worldwide guidelines requiring air quality to be monitored with gas sensors; even though modern, fuel-efficient vehicles emit significantly less toxic gases (and particulate matter) compared to their predecessors.

Wherever gases may occur, it must be ensured that gas concentrations do not exceed the specified limits. During tunnel construction, harmful gases can escape from the rock, and these must be monitored. After completion, the focus is on the exhaust gases. These are usually the harmful exhaust fumes from petrol engines (CO) and diesel engines (NO2).

The continuous and exact measurement of the smallest NO2 concentrations forms the basis for controlling the tunnel ventilation. In a first step, the ventilation system is ramped up, and if this does not reduce the pollutant concentration sufficiently, optical and acoustic warning signals warn to evacuate the tunnel.

CO Exhaust Gases from Petrol Engines

Carbon monoxide is formed during incomplete combustion of petrol. It is completely odourless and colourless. At the same time, CO is a highly toxic (poisonous) gas that is lethal even in small quantities. In simple words, the ingestion of CO hinders the oxygen supply; the transport of oxygen in the blood of the human body is massively affected. Since humans do not have a sensory organ that protects them from CO, suitable gas sensors are used for safe detection.

NO2 Exhaust Gases from Diesel Engines

Nitrogen oxides are formed during combustion of diesel. NO2 is a very strong respiratory poison, damages the mucous membranes and irritates the eyes. NO2 is responsible for coughing, bronchitis and even pulmonary oedema. Humans can detect NO2 through their sense of smell, as it has a chlorine-like odour. But the concentration emitted by car exhausts is usually not sufficient to be detected by the sense of smell. Here, too, a gas sensor must be used for reliable detection.

Solutions from MSR-Electronic for Reliable Detection of Gases in Tunnels

Gas sensors (type SC2) with an electrochemical sensor element are used for continuous measurement of the CO and NO2 concentrations in the tunnel air. The gas sensors meet the requirements of the EN 50545-1 standard necessary for tunnel construction.

The gas sensor SC2 is an exchangeable sensor including digital value processing, temperature compensation and self-control for the continuous monitoring of the ambient air. It is used to detect toxic gases or for oxygen monitoring.

In addition to the electrochemical sensor element and the measuring amplifier, the sensor contains a μController for measured value processing. All relevant data and measured values of the sensor element are stored in the μController in a fail-safe manner and are transmitted digitally via the local bus to the sensor board (e.g. SB2 or MSB2). The calibration management is also integrated in the μController of the sensor.

Calibration can be done either by simply replacing the sensor or by using the integrated, convenient calibration routine directly at the system.

The Heart of the System – The Digital-Gas-Controller DGC-06

The DGC-06 controller from MSR-Electronic evaluates the measured values of the gas sensors. It is used in gas measurement technology for monitoring and warning of toxic and explosive gases and vapours as well as of Freon refrigerants. Numerous adjustable parameters and set-points permit individual adaptation to many applications. This means that the controller also fulfils the functions of monitoring carbon monoxide (CO) in garages, tunnels and loading zones, for example, and is compliant with EN 50545-1.

The Digital-Gas-Controller DGC-06 has been developed for large systems or even for extensive connections. Everything is possible, from complex multi-storey car parks to access permissions that are switched by gas alarm.

The Gas-Controller series DGC-06 can monitor and manage up to 128 gas sensors, 96 digital and/or 32 analog (4–20 mA) sensors. 4 free adjustable alarm thresholds are provided per sensor. For the alarm messages the controller system offers up to 128 relays with potential-free change-over contact and up to 16 analog outputs with 4–20 mA signal.

Further information on MSR products can be found here in the current MSR-Electronic online catalog or in the webshop: www.msr-24.com.

MSR-Electronic is a manufacturer of fixed gas warning systems with decades of experience in the field of building automation and gas measurement technology. The international company with headquarters in Germany has a wide range of methods for the detection of toxic and combustible gases. On this basis MSR-Electronic develops individual gas sensors, controllers and warning devices for many applications, such as parking garages, tunnels, petrochemical industry or shipping. The products meet more than the general standards and regulations and can therefore guarantee the safety of the plant. www.msr-electronic.de/en