Inrotech, a designer and manufacturer of automated welding solutions for shipbuilding, renewables, offshore and heavy industries, has chosen 2D/3D laser profile scanners from Micro-Epsilon for use on its ‘Inrotech-Crawler’ welding robot, which calculates welding processes in advance before carrying them out.

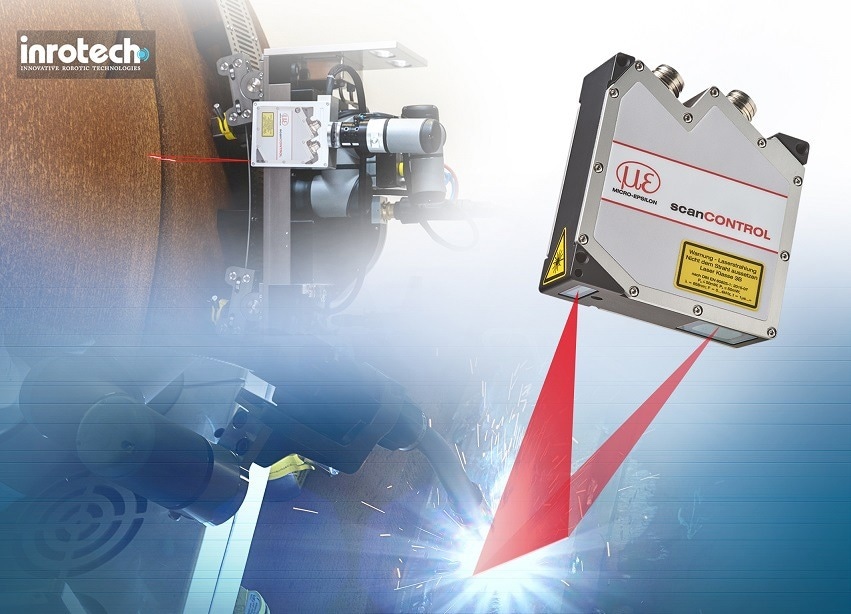

The scanCONTROL 2900 laser profile scanner measures the geometry of the seam to be welded before the actual welding process starts. Image Credit: Micro-Epsilon

The scanCONTROL 2900 laser profile scanner measures the geometry of the seam to be welded before the actual welding process starts. Image Credit: Micro-Epsilon

A scanCONTROL 2900 laser profile scanner from Micro-Epsilon is mounted on the Inrotech-Crawler and measures the geometry of the seam to be welded before the actual welding process starts. Only these high precision profile measurements enable the welding process to be automated. Due to its compact, lightweight design with integrated controller, the scanCONTROL 2900 is ideally suited to this measurement task. In this particular application, the laser scanner has a measuring width of 100 mm, a measuring rate of 300 Hz and a resolution in the Z-axis of 12 µm.

Various connectivity options offered by the SDK (Software Development Kit) enable Inrotech to directly transmit the profile data, from the sensor, calibrated to their own software via the scanCONTROL DLL. The Weldlogic technology from Inrotech then calculates, among other things, the number of weld passes, the position of the weld seams, the weld speed and the oscillation width required to produce a quality weld. Directly after the calculation, the Inrotech-Crawler automatically performs the welding process.

The welding robot enables the scanning of weld geometries such as plates or curves with various characteristics. Based on the optimal exposure time control and high resolution, the laser profile scanner reliably measures almost any measurement object.

Designed for mobile applications, the Inrotech-Crawler is ideal for different environments, for example, for pipeline welding tasks in the oil & gas industry, offshore, shipbuilding, wind turbines and building construction. A resistant sensor is the base requirement in this and many other environments. The scanCONTROL 2900 laser profile scanner is ideally suited to these requirements and is integrated into a protective housing by Inrotech.

The scanCONTROL 29x0 series of 3D laser profile sensors are designed for industrial measurement tasks where compact design and high accuracy are required. Due to their high resolution, self-contained housing, versatility and excellent price-performance ratio, the scanners are particularly suitable for static and dynamic applications, for example, on robots. The scanners measure and evaluate a variety of geometrical features such as angles, steps, gaps, distances and extreme values.