Gas sensors from MSR-Electronic monitor concentrations of a wide range of gases. MSR-Electronic convinces with its wide range of detectable gases and enables solutions for fixed gas warning systems from simple stand-alone devices to more complex systems with up to 128 gas sensors.

Image Credit: MSR-Electronic GmbH

Image Credit: MSR-Electronic GmbH

Gas Monitoring for Buildings, Industry and Shipping

In various enclosed areas such as parking garages, refrigeration plants and laboratories, everywhere where gas is handled and/or an increased gas concentration can occur, special protective precautions are prescribed. Especially when handling toxic and combustible hazardous gas substances, constant monitoring is mandatory.

MSR-Electronic also has the necessary approvals for the use of gas sensors in the industrial sector, e.g. in the petrochemical industry and in marine applications.

Recommendation by MSR-Electronic

MSR-Electronic recommends the use of gas detectors even in areas where legal gas monitoring is not required in order to protect people's health and at the same time the installations.

Gas Detection in a Variety of Applications

Parking Garages, Tunnels, Loading Zones

With the typical gases CO/NO2/LPG, car parks and tunnels are among the main applications for gas detectors. The European Standard EN 50545 serves as a guideline for car park applications.

Refrigeration Systems

Depending on the amount of gas, the installation site and the refrigerant used, refrigeration systems are equipped with gas detectors in accordance with EN 378.

Industry

Protection of health and equipment under extreme industrial conditions - thanks to the wide range of methods for the permanent detection of gases, numerous applications can be served.

Buildings

In rooms where people are regularly present, gas detection systems are used to detect air quality and protect against combustible and toxic gases.

Food & Beverage

This application includes pubs, brewing and fermentation cellars, breweries, wine cellars and beverage bottling plants where CO2 leakage during soft drink carbonation or oxygen deficiency are monitored.

Laboratory, Medicine and Research

Whether in research for new medicines, in the production of medical products, in hospitals, medical facilities or laboratories - a variety of toxic and combustible gases also occur here.

Biogas Plants

Methane sensors have proven to be a reliable and convenient solution for detecting leaks in the membrane and in the generator feed of biogas plants at an early stage.

Marine Applications

Ships are risk areas as there is no possibility of escape. Early detection of gas leaks such as methane, CO2, H2, NH3 is done by DNV-certified equipment.

Waste Disposal

Employees in the waste disposal industry are exposed to hazards from toxic and combustible gases. Continuous control of emission levels and of the escape of gases such as CO2/H2S/hexane etc. can be ensured thanks to fixed gas warning systems.

Hydrogen

H2 is a very reactive gas that needs to be monitored throughout its life cycle, in production, logistics, storage and in the use of the gas to power trucks or ships, to produce steel or to otherwise generate energy.

Aquacultures

Water treatment and disinfection play an important role in aquaculture systems. Usually, ozone is used to disinfect the systems, which poses a great risk to health.

Rechargeable Batteries

Batteries are present in a wide range of applications. In order to detect the danger of the Thermal Runaway at an early stage, gas detectors have proven to be a reliable tool.

Product and Service Range of MSR-Electronic

The portfolio includes gas sensors and controllers for various gases and the appropriate accessories such as warning devices, test gases and calibration tools. Support with the design of your systems, commissioning and maintenance can be covered globally by the large partner network.

Recalibration

Thanks to the X-Change technology, there is no need for the time-consuming procedure of on-site calibration. By replacing the sensor head with a calibrated one, calibration is simplified. Even if a gas sensor has reached the end of its service life, it is not necessary to replace the entire transmitter, but only the exchangeable head. Alternatively, the on-site calibration can be ordered from a certified partner or from MSR-Electronic.

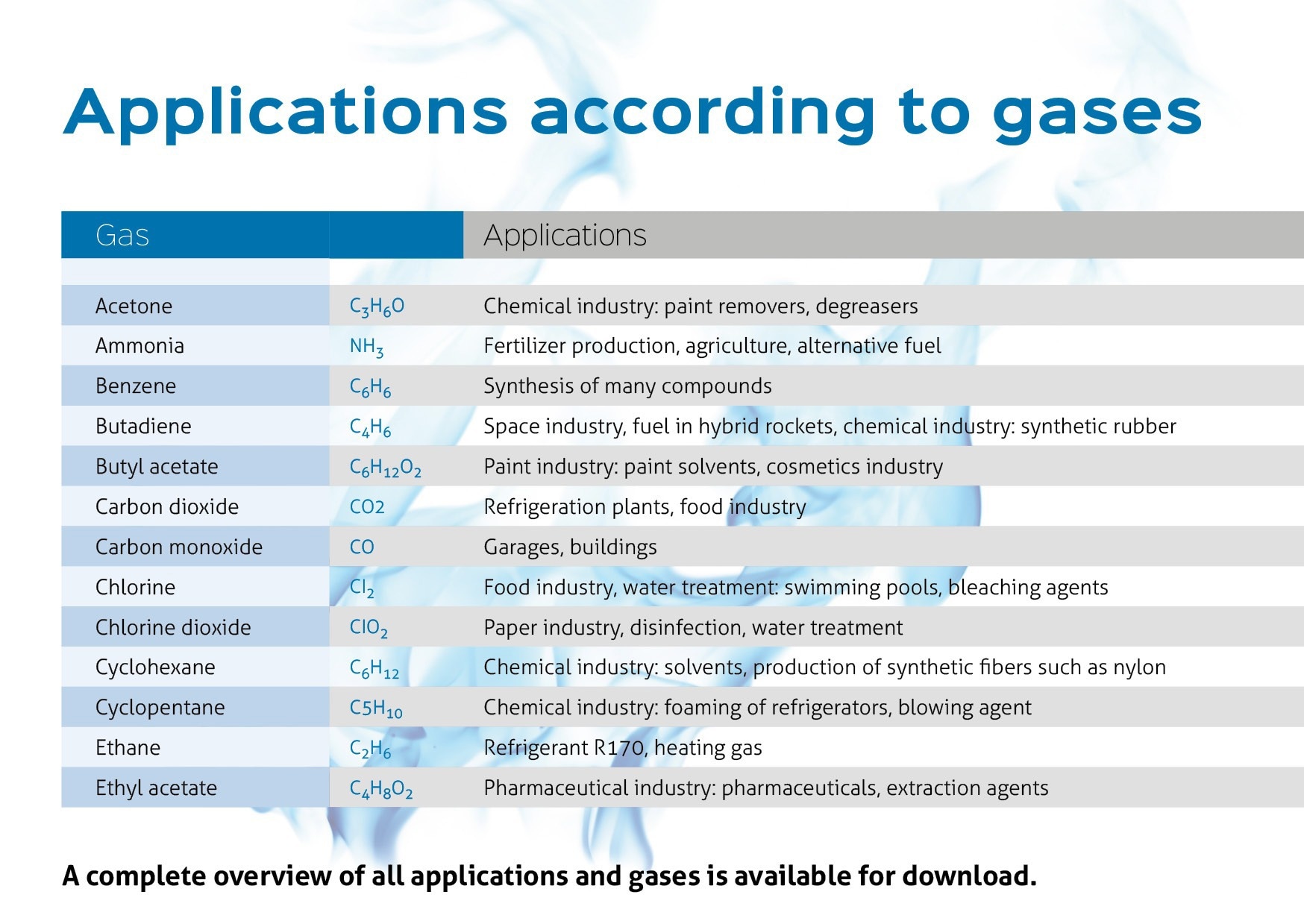

Download: A complete overview of the gas and application variety can be found here.