Practical applications of the proposed sensor. Image Credit: Microsystems & Nanoengineering

Recent advancements in flexible pressure sensors, designed to mimic the sensitivity of human skin, are revolutionizing fields like interactive technologies, health monitoring, and robotics. These sensors utilize diverse microstructural strategies—such as pyramidal, dome, wrinkled, and layered designs—to enhance sensitivity and durability.

Despite their potential, the complexity of their manufacturing processes remains a challenge. In response, innovative approaches are being developed to simplify the fabrication of these sensors, improve their pressure detection range, and increase stress tolerance. These improvements are pushing the boundaries of sensor technology, enabling more efficient and versatile applications.

In this new study, the researchers have presented a cutting-edge flexible pressure sensor renowned for its extraordinary resilience under ultrahigh stress. This technological breakthrough features periodic microslits embedded in a composite of multi-walled carbon nanotubes (MW-CNT) and polydimethylsiloxane (PDMS). This design marks a significant advancement in the capabilities of pressure sensors.

This unique structure considerably improves the sensor’s capacity to withstand severe pressures, with experimental tests showing a stress tolerance of 400 kPa and theoretical predictions up to 2.477 MPa. The design achieves a high sensitivity of 18.092 kPa−1, setting a new milestone for pressure sensor performance.

The use of microslits allows for significant deformation under high pressure, expanding the sensor's working range while avoiding the difficulties of standard molding and demolding methods. This feature, together with the appropriate MW-CNT/PDMS ratio, enables numerous contact points inside the sensing film and between the periodic sensing cells while under load.

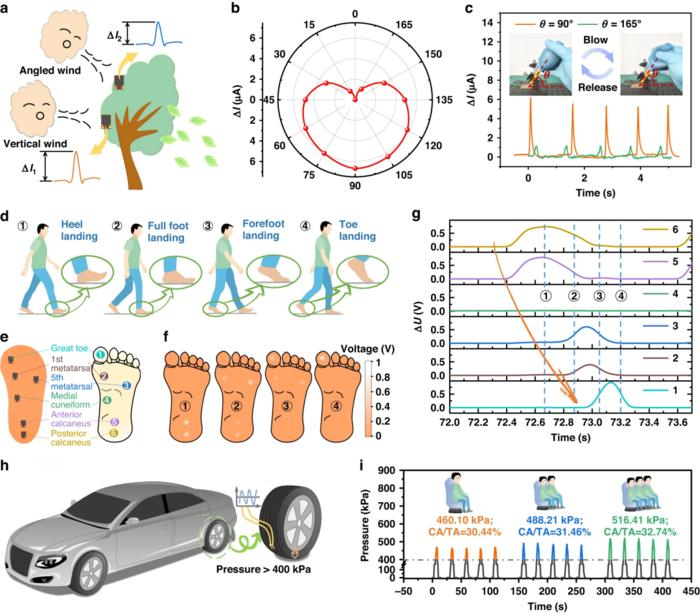

These qualities work together to improve the sensor's performance, allowing for applications such as wind direction monitoring, high-stakes health monitoring, and vehicle load identification.

This innovative microslit strategy not only simplifies the sensor's fabrication process but also significantly extends its application range, from health monitoring to ultrahigh pressure sensing applications such as vehicle load detection.

Lead Researcher

The sensor’s high-stress tolerance and sensitivity have far-reaching implications for a variety of industries, including robotics, health monitoring, and automotive. Its ability to detect minute pressure changes offers new possibilities for noninvasive health monitoring equipment.

Journal Reference:

Wang, S., et. al. (2024) Flexible pressure sensors with ultrahigh stress tolerance enabled by periodic microslits. Microsystems & Nanoengineering. doi:10.1038/s41378-023-00639-4