Kunststoff Cluster of Austria recently hosted a seminar at which Dr Friedrich Kastner, managing director of pipe and fitting producer of Ifw Mould Tec, and Prof Werner Posch from the Upper Austrian University in Wels presented papers, focusing on the quality of moulding of injections for pipe fittings.

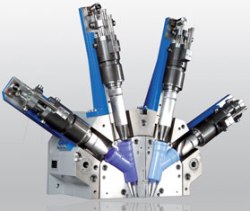

Ifw's Xpress Colling System

Ifw's Xpress Colling System

The solution is based on a mould that includes close contour conformal cooling technology while balancing hot runner channels. This removes melt viscosity during production that is essential for zero-defect production. The device has sensors to control the mould and fabric quality. The company is procuring sensing devices from the Swiss company Kistler.

Ifw will use its XCS Xpress Cooling System for the current project. The system ensures that the temperature is distributed evenly, helping to reduce stress and damage to parts. It will reduce cycle lengths by 20% and can be either deployed on mould cores or cavities.

The Mold4ProdE EU research programme will help develop smart moulds to enhance productivity. Data mining techniques use data from virtual sensors in a CAD mould model in an endeavor to enhance sensor count and placement in the mould and to remove faults in production.