Apr 24 2010

A bridge collapses every week in the U.S. despite a sum of $400 million being spent every year for inspection.

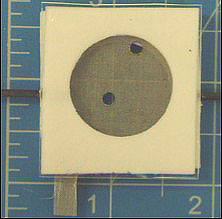

MATECH EFS Sensor

MATECH EFS Sensor

Such bridge collapses and closures are caused by major inefficiencies of existing bridge inspection techniques, wherein around 90% of cracks due to fatigue are missed out. In addition, more than 80% of cracks that are identified by the inspectors are proved as false positives subsequently. In such a scenario, to secure the infrastructure of the U.S. there is a need for a cost-effective system that saves lives as well as money.

The right answer to this issue is the proprietary electrochemical fatigue sensor developed by MATECH. This state-of-the-art technology has proved its worth for more than 25 bridges in 10 states in the U.S. and also across the country’s railroads and various Department of Transportation (DOT) structures.

The Reston, Virginia-based American Society of Civil Engineers (ASCE), the U.S.’ oldest national engineering society and the leading publisher of information on civil engineering, and producing technical content more than 55,000 pages annually, has estimated that the nation faces an infrastructure backlog to the tune of $2.2 trillion, highlighting the increasing infrastructure crises.

The University of Maryland’s Dean of the School of Public Policy Donald F. Ketti had discussed this infrastructure crises in his article in the GOVERNING magazine published in April 2010. He informed that this problem is increasing and one among every eight U.S. bridges is deficient structurally, while 85% of the public transit systems are finding it difficult to cope up with the increasing number of riders.