Germany-based Micropelt and the R&D centers of ABB at Daettwil, Switzerland, and Ladenburg, Germany are utilizing energy harvesting for powering wireless sensors.

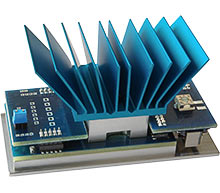

Micropelt Thermal Energy Harvesting Evaluation Kit

Micropelt Thermal Energy Harvesting Evaluation Kit

This joint development project by ABB and Micropelt has resulted in the incorporation of a harvesting unit fir thermal energy comprising two MPG-D651 Micropelt thermogenerators, each of 6 mm2size, into an ABB WirelessHART temperature transmitter unit.

The temperature gradient required between the medium being sensed and surrounding air is 30°C to power the mesh network-based wireless equipment. The energy harvesting unit functions as a sustainable free power supply unit without the need for maintenance or expensive batteries.

The project leader of ABB, Dr. Marco Ulrich, considers this development as a vital breakthrough. Ulrich has revealed that wireless instruments enable broader and more flexible utilization of sensors at substantially reduced expenditures, more so in difficult operating conditions.

Dr. Joachim Nurnus, the CTO of Micropelt, has further elaborated that the technology has eliminated the usage of many high-power batteries. More importantly, the technology has helped the creation of more sensing points that will enable a higher degree of energy efficiency in production.

Balanced use of process equipment use is also possible with this technology, which facilitates switch over to maintenance processes that are cost-effective. Dr. Nurnus has revealed that Micropelt has only recently become aware of the large ecological and economical capability of omnipresent wireless sensing techniques. Dr Nurnus said that Micropelt intends to share the technology with its customers, in addition to developing prototypes and demonstrators for self-sustaining networks during the forthcoming sensor shows to be held in Nuremberg, Germany, during May 2010 and in Chicago, IL, during June 2010.