Jun 29 2010

Nanotechnology research center, imec, in collaboration with its Ghent University-associated laboratory, has unveiled ethanol vapor sensors that are SOI microring resonators coated with 3.5nm ZnO nanocrystal films.

This gaseous ethanol optical sensing technology allows for 100ppm vapor concentration detection. These optical sensors are ideal components to satisfy the growing demand for sensitive, low-cost, low-power, and compact, gas detection systems. This technique can also be extended to include detection of certain other gases by using specific functional molecules to dope the metal oxides.

Ethanol Vapor Sensor Coated with ZnO Nanoparticle Film

Ethanol Vapor Sensor Coated with ZnO Nanoparticle Film

The ethanol vapor sensors from imec and INTEC demonstrate SOI technology’s potential for low-cost, and low-power optical gas sensing. Micropatterning technique advancement will allow for the efficient coating of several microring resonators to accomplish multiplexed and integrated optical chip multi-gas sensing.

The SOI technology can prove to be advantageous in comparison to other technologies such as electrochemical and catalytic. These optical gas sensors can operate at room temperature, are compact, and suitable for remote multiplexing and sensing. Unaffected by electromagnetic interference, they have no involvement with direct electrical contacts. In explosive gas environments, they provide risk free operation. The metal oxide coatings are stable and provide robust and reliable solutions. Compatibility with CMOS fabrication tools and low cost mass fabrication add to their attraction.

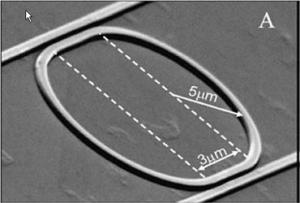

Normally, 193 nm deep-ultraviolet photolithography, combined with dry etching, is used to fabricate high-Q microring resonators of 5µm-radius. Colloidal suspensions of ZnO nanoparticles with a diameter of 3.5nm are used to prepare the ring resonators’ local coating. This results in raising the Q values of the SOI microring resonators to about 15,000. Gas adsorption is possible in a large area, as the coating is porous. The resonance wavelength shift and change that occurs in the ZnO refractive index as a result of evanescent field interaction, is measurable. For example, a shift of 500pm occurs when there is 1500ppm exposure. This sensing configuration allows for 100ppm ethanol vapor concentration and the detection limit estimated is below 25ppm.