Nov 25 2012

Image Credit: Iaremenko Sergii/Shutterstock.com

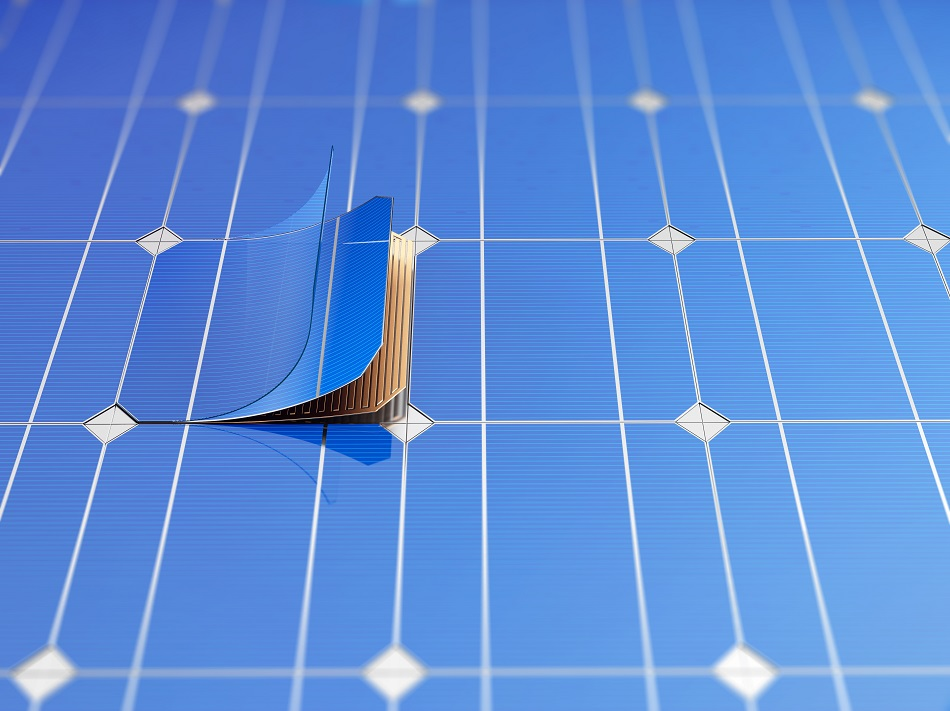

Polymer solar cells are flexible photovoltaic cells (PV cells) with the ability to generate electricity from sunlight using a PV effect. Plastic or organic solar cells are polymer solar cells, which are light in weight.

Polymer solar cells are now being used to develop self-powering skin that can generate electricity. It is possible to stretch these solar cells up to 30% above their actual length and they will restore to their normal length intact and without power loss.

Types of Solar Cells

There are two major types of solar cells - crystalline silicon and thin-film.

Crystalline Silicon Solar Cells

Crystalline silicon technology is primarily used to manufacture PV in the semiconductor industry. The PV cells thus produced are found to have an energy conversion efficiency in the range of 11-16%. The crystalline silicon solar cells have high efficiency and poor light absorption characteristics.

Crystalline silicon solar cells are classified into two types:

- Mono-crystalline - solar cells made of thin wafers of a single crystal silicon ingot having high purity.

- Polycrystalline - produced from a silicon crystal that has multiple functional capacities. The cost of a polycrystalline cell per watt is nearly 15% less than that of the mono-crystalline cell.

Thin-Film Solar Cells

Solar cells have been manufactured using inexpensive semiconductor materials like copper indium gallium selenide (CIGS), amorphous silicon (a-Si) and cadmium telluride (CdTe) owing to the high price of crystalline silicon PV cells. These semiconductor materials are thin and have a good light absorption capability. CdTe is the leading PV cell manufacturing technology followed by a-Si and CIGS.

Optical Connections and Sensor Skin Design

The sensor skin has two components - a VLSI chip and a flexible cube. The VLSI chip is used for performing the following functions:

- Optical intensity measurement

- Receiving optical power

- Processing signals

The flexible cube is attached to the VLSI chip in order to measure six stress components present around the VLSI chip. The sensor chip is capable of estimating the light intensity at several points. The flexible cube structure consists of eight holes leading to photodiodes. The cube’s deformation can be identified by the sensor using the change in light intensity at the photodiodes.

Organic Solar Cells and Flexibility

An ultrathin organic solar cell is 1.9 µm thick, out of which 1/4th functions as an active photovoltaic cell. Some of the well-known materials used to produce the OPV cells are:

- Poly(3,4-ethylenedioxythiophene):poly(styrenesulphonate) (PEDOT:PSS)

- (6,6)-phenyl-C61-butyric acid methyl ester (PCBM)

- Poly(3-hexylthiophene) (P3HT)

- Ca/Ag evaporated metal electrodes

Solar devices made on glass substrates using the above materials are said to have around a 4.3% efficiency.

Such ultra-thin devices are capable of continuous optoelectronic operations when subjected to heavy mechanical deformation. When subjected to compression and stretching, these devices retain the properties of a functional OPV cell even at 80% compression, making this material highly adaptable. On re-stretching this structural component, the device switches back to its pre-compression state. These results show that a functional OPV cell has an impressive 400% tensile strain.

This can be explained as an increase in light-harvesting caused by micro-texturing upon compression of the solar device. During compression of this device, there is an increase in the amount of light-absorbing polymers per unit area. This enhances overall light absorption.

Conclusion

Subsequently, South Korean and US engineers designed an artificial skin, which acts as a flexible, sensitive and low cost strain-gauge sensor. The engineers got their inspiration from the sensing ability of beetles. They created a tiny bed of several polymeric nanofibres of length 1µm on a solid base. They replicated this bed and kept the second one on top of the first bed in such a way that the Pt-coated fibers come in contact with each other.

The researchers were then able to measure the electrical current passing through the nanofibers as they intermingled with each other. They were also able to estimate the torque, sheer, and pressure of the nanofibers. This artificial skin proved to be extremely sensitive to tiny things placed on it and was able to sense the movement of a tiny bug, a water droplet and even the human heartbeat.

The engineers expect that this discovery is much simpler compared to the complex sensors currently used in robots. In the future, this promising new technology may help in restoring the sensation in human beings who have lost it, even in artificial limbs.

Sources and Further Reading

- Yamada. k, Goto. k, Nakajima. Y, Koshida. N, Shinoda.H. (2002) A Sensor Skin Using Wire-Free Tactile Sensing Elements Based on Optical Connection. Published in SICE 2002. Proceedings of the 41st SICE Annual Conference. Pages 319–322.

- Kaltenbrunner. M, White. M.S, Glowacki. E.D, Sekitani.T, Someya.T, Sariciftci. N.S, Bauer. S. 2012. Ultrathin and lightweight organic solar cells with high flexibility. Macmillan Publishers; pages 1–7.

- Pang C, Lee G, Kim T, Kim SM, Kim HN, Ahn S, Suh K. A flexible and highly sensitive strain-gauge sensor using reversible interlocking of nanofibres. Nature Materials. 2012; doi:10.1038/nmat3380.

This article was updated on 14th February, 2020.