As the performance of displacers is variable, and these often require routine maintenance, the efficient measurement of levels within petrochemical plants and refineries can be impacted.

Archimedes iconic ‘short-span’ level measurements remain a solid concept and method, but with today’s technology there are much more cost-effective and reliable options available.

Displacers must be regularly maintained in order to keep them working at their best. This is especially the case when displacers are susceptible to build-up in the displacer body, requiring frequent ‘blowdown’ to address.

The Problem

Blowdown procedures can take up to two days, needing a large amount of supplies to undertake. A displacer is a wholly mechanical device, meaning that components can wear out and will need replacing. This is considered to be a fact of life for mechanical devices, but this does impact on the total cost of ownership and can have a negative effect on the device’s reliability.

The issue with using displacers and Differential Pressure devices to obtain level measurements on single liquids is the method’s dependence on there being a constant and specific gravity of the process liquid.

This issue is made worse when using an interface level measurement as the output will be proportional to the difference within the specific gravity of the two interfacing liquids. Should be difference between these two specific gravities be 0.1, the displacer’s calibration would be ten times as sensitive to change in specific gravity as a result of composition variations in the liquid or changes in temperature.

The Solution

Radio Frequency (RF) based level sensing has quickly become one of the foremost technologies in the indication and control of total level or interface level applications. RF technology is almost naturally suited to working with most interface level applications – such as conductive vs. insulating liquids – whether these are normal or inverted.

Where there is a defined (clean) separation between the conductive and non-conductive phase, RF is able to produce a precise indication of the interface’s location via the sensing element. Should the interface develop an emulsion or ‘rag’ layer which separates the upper and lower phases, RF technology can show that the interface is located in the rag layer where the emulsion reverses from an oil-external to water-external configuration.

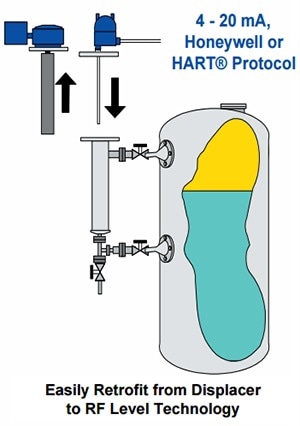

RF level transmitters from Drexelbrook are available with a range of outputs – analog only (4-20 mA), HART digital or 4-20 mA Honeywell digital. The Honeywell and HART instruments can be calibrated via regular handheld communicators or propriety software (PC-based) that has been developed specifically for communication and calibration. There is no need to vary level in a lot of cases.

Drexelbrook RF transmitters can measure total liquid level or interface level regardless of temperature, pressure variations or density. The technology does not require moving parts and does not require routine maintenance. Additionally, the RF Admittance measurement is practically unaffected by the build-up of process material on the sensing element itself.

RF technology is the best level measurement technology for interface measurement, and Drexelbrook can provide the whole cage/chamber assembly where required, or even retrofit the level sensor with a mating head flange so it can work with a range of common displacer chambers.

This solution is as simple as unbolting the head flange before removing the displacer assembly and the transmitter (either pneumatic or electrical). The equipment is then switched with an RF sensing element which is specifically designed for the process measurement. Here, fluorocarbon-insulated sensors are able to reduce or even completely eliminate the need to use special heat treatment or exotic metals.

Drexelbrook’s True Level is the most advanced solution for displacers which are regularly affected by density changes due to products that are ‘off spec’ or specific gravity changes induced by temperature.

The True Level is a dual measurement instrument based in a single, easy-to-use sensing element. It is able to continually self-compensate for changes in electrical properties which can occur due to stark changes in composition or temperature.

The only requirement for this instrument to work is product homogeneity, so that both the composition and the level sensing parts of the sensing element are exposed to the same electrical characteristics.

The True Level is available with a 4-20 mA, HART protocol output. Every RF level transmitter from Drexelbrook is available with a 2-wire configuration that is intrinsically safe, suitable for installations in areas that are classified as Class 1, Div. 1 hazardous.

This information has been sourced, reviewed and adapted from materials provided by Drexelbrook.

For more information on this source, please visit Drexelbrook.