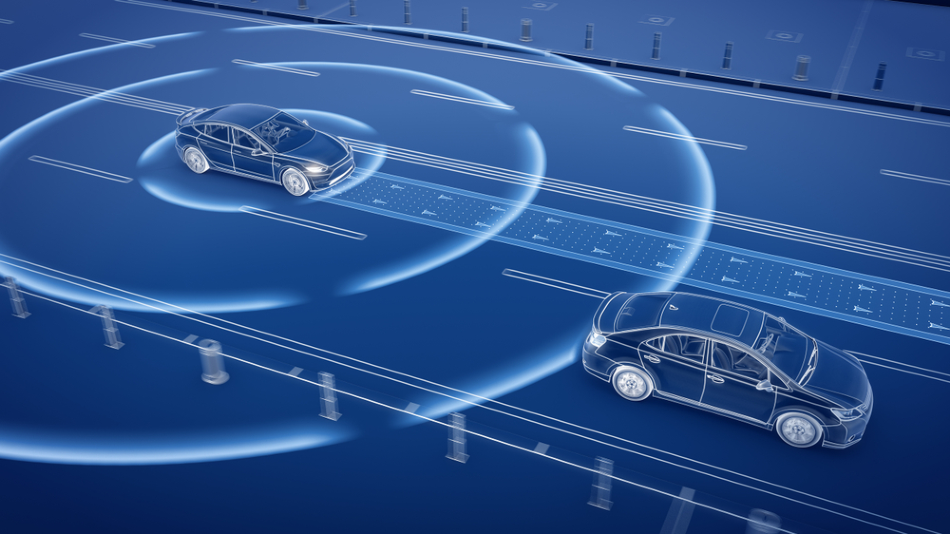

Within contemporary vehicles and mobile equipment, the quantity on sensors is continually on the rise. Sensors are a crucial element for the enjoyable, safe and economical use of a wide variety of vehicles.

Image Credit: Shutterstock/temp-64GTX

Demanding conditions such as extreme temperatures or ongoing vibrations put a lot of pressure on the stability and sturdiness of sensors in automotive applications. As well as this, the sensors used here must be compact, relatively low in cost, and has economical energy use.

First Sensor creates and produces ground-breaking and dependable OEM pressure sensors, open to modification to your individual needs, drawing on the company’s excellent levels of expertise, to be integrated into vehicles and mobile equipment.

As First Sensor produces all of its central components, the company can safeguard the long-term accessibility of goods marketed for series production and the aftermarket. Sensors can be purchased in a variety of pressure ranges, from vacuum to high pressure, and with custom-designed and electrical or pressure connections.

In addition to this, a broad array of analog and digital interfaces, such as ratiometric signals, SENT, LIN, PWM and I²C, are on offer. All commissioned OEM pressure sensors are developed and produced to meet the standards of the quality management system for the automobile industry ISO/TS 16949.

First Sensor Solutions for the Vehicle Industry

.gif)

Image Credit: First Sensor

First Sensor Solutions for Fuel Applications

With the option of built-in temperature sensors; tank pressure measurement, tank leakage diagnostics and fuel delivery are just some of the applications for OEM pressure sensors. The sensors can be attached directly within the tank, where they are wholly encircled by fuel or fuel vapors, or can be attached to the tank wall.

Both the relative and absolute pressure measurements of volatile liquids including diesel, methanol, gasoline and ethanol can be achieved with First Sensor’s tank pressure sensors. Unique technologies and methodologies are available for in-tank measurements which allow for the saving of space, minimal maintenance requirements, and sensor solutions that won’t break the bank.

As well as directly building the sensor into the fuel delivery component, an alternative is to attach it to elements of the fuel supply system, for example, a tank flange or a fuel line. As these extremely sensitive sensors are capable of distinguishing minute deviances in the fuel tank’s pressure levels, they are highly suitable for management of leaks.

To control the air intake and extraction of the tank, First Sensor’s pressure sensors observe negative pressures and overpressures within the fuel tank.

Further First Sensor Solutions for the Vehicle Industry

By determining the negative pressure for managing the vacuum pump in break booster processes, First Sensor’s vacuum pressure sensors can offer high levels of support for the action of braking. These durable devices can be used in polluted environments with dirty air, and will remain operational in temperatures from -40 °C to +135 °C.

In addition to this, the vacuum sensors support the reduction of carbon emissions by integrating with automatic start-stop systems in vehicles.

For electrohydraulic power-assisted steering, extreme-pressure sensors with numerous incorporated pressure connections for determining different pressures and temperatures are available. It is also possible to customize modular high-pressure sensors for usage in a broad range of hydraulic pressure applications in vehicles and machinery.

In order to set the damping of the engine suspension in sports cars and other vehicles, pressure sensors with quick reaction times are needed to allow for reaction to the method of driving and lane structure immediately. Pressure sensor solutions with quick signal processing through the use of application-specific integrated circuits (ASSP/ASIC) are available from First Sensor.

Within the air-conditioning structures of vehicles, First Sensor’s sensors quantify pressure and, if required, temperature in closed-loop refrigerant circuits. The sensors are compatible with standard refrigerant R134a, in addition to environmentally-conscious options such as R1234yf and R744 (carbon dioxide).

In accordance with IP6K9K, the sensors are designed temperatures in the range of -40 °C to +165 °C, and are shielded from water and dust.

For extremely responsive and accurate measurement of very low differential pressures in vehicles and machinery, First Sensor delivers ground-breaking flow-based pressure sensors with measuring ranges from 25 Pa (0.25 mbar), in addition to the highest resolution and counterbalance stability.

Exhaust gas aftertreatment (SCR) systems, common rail injection up to 3000 bar, high and low pressure applications for hydrogen fuel cell vehicles and exhaust gas recirculation systems (EGR) are just some of the additional application fields for First Sensor’s OEM pressure sensor solutions.

This information has been sourced, reviewed and adapted from materials provided by First Sensor AG.

For more information on this source, please visit First Sensor AG.