The LM80, LLT100, and LM200 can accurately measure the distance to the targeted surface by using a time-of-flight calculation.

These level transmitters use eye-safe, invisible, infrared laser pulses to measure the distance to the surface. The on-board microprocessor computes the distance by multiplying the known speed of light by the travel time of the laser pulse from the transmitter to the surface and back.

Thanks to the very little divergence (<0.3°) of the laser beams, accurate targeting is made easy even in vessels or silos that have internal structures. In addition, there is no interaction between the narrow beam and local structures or build-up on vessel walls, thus making measurements highly reliable even when there are changes in the environment. This eliminates the need for reconfiguration, prevents down-time, and reduces the lifetime cost.

Industries Served

- Aggregates

- Mining and construction

- Chemicals

- Fertilizers

- Oil and gas

- Power generation

- Pulp and paper processing

- Water and wastewater

- Food and beverage

Customer Benefits

- Narrow beam not affected by surrounding structures

- Maintenance free

- Non-contact

- Very flexible installation and can be aimed at an angle

- No echo mapping required

- Very accurate

- Rapid response

- Range up to 200 m

Made for Industrial Applications

- Measures through dust and fog

- Certified for high pressures

- Approved for hazardous areas

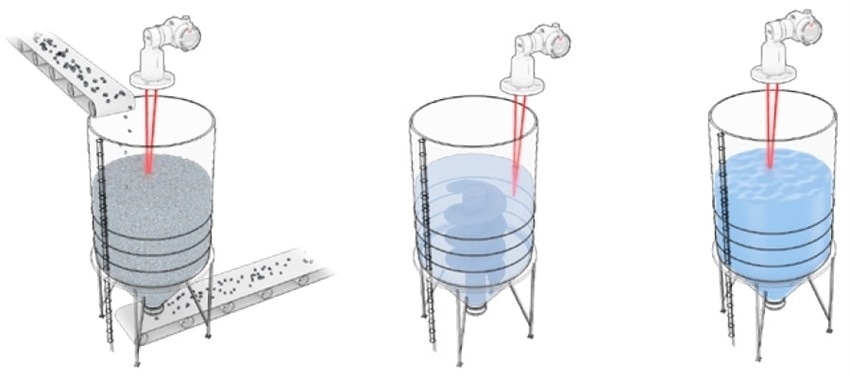

Laser level transmitter used in bulk solids silo, tank with an agitator and liquid tank. Image Credit: ABB Level Measurement Products

The New Standard in Industrial Laser Level Transmitters

The LLT100 is the most recent generation of laser level measurement transmitters. Riding on the success of the LM80, it incorporates a host of innovative technologies to specifically modify laser time-of-flight measurement according to the requirements of industrial applications.

LLT100 laser level transmitter. Image Credit: ABB Level Measurement Products

Hence, the LLT100 can measure all solids or liquids, even transparent liquids, by using powerful signal processing, laser pulse control, and precise timing circuits. The level of liquids can be measured at up to 30 meters (100 feet) and the level of solids at up to 100 meters (330 feet). All of this comes in a 2-wire powered device!

The LLT100 is specially designed for challenging industrial environments and it offers continuous, non-contact level measurement capabilities for inventory management and process automation in industries such as aggregates, chemicals, mining, oil and gas, power, food and beverages, pharmaceutical, pulp and paper, and water and wastewater.

The LLT100 is available with a variety of process interfaces common in the industry

- Standard aluminum or stainless steel flange

- High-pressure flange

- Hygienic triclover flange

Clear Benefits

Optimize process or inventory management

- Independent of material properties and dielectric constant

- Precise measurement of any solid or liquid

Low cost of ownership

- No reconfiguration when the environment changes

- Fast and flexible installation

- Single product configuration works for many applications

Convenient

- Adjustable embedded graphical user interface

- 2-wire powered and HART 7 communication

- Easy setup menu

Reliable

- Dust and fog penetration capabilities

- Approved for use in hazardous area class 1, division 1 and zones 0/1

- Accurate measurement at distances up to 100 meters (330 feet)

Laser Level Measurement for Solids and Liquid Stored in Vessels

ABB laser level transmitters used in municipal wells to measure wastewater level. Image Credit: ABB Level Measurement Products

Lasers allow level monitoring measurement for a wide variety of dry bulk solids and liquids contained in vessels. They are capable of measuring through narrow gaps and down to the bottom of vessels. The lasers function in all types of storage vessels, including tanks, silos, hoppers, bunkers, and feed chutes.

Laser levels are particularly useful when measuring curved surfaces, such as biogas balloons.

As the concept of echo mapping is not needed for laser level measurement, it offers a maintenance-free and reliable measurement method for any application where build-up is formed on the walls of the vessel or when there are changes in the local environment.

Additionally, multiple laser level measurement products do not get in the way of each other, even when proximally placed together.

- Accurate, fast, and long-range positioning or anti-collision of moving machinery

- Easy measurement in silos with internal structure and/or with build-up

- Ideal for bins, silos, and tank for grain, plastic pellets, powders, dry bulk solids, coffee

- Ideal for all types of liquids, regardless of their types, such as oils, water, liquid polymers, etc.

This information has been sourced, reviewed and adapted from materials provided by ABB Level Measurement Products.

For more information on this source, please visit ABB Level Measurement Products.