All of the advantages of laser level measurement are provided to the food and beverage and pharmaceutical industries, by the LLT100 hygienic model.

LLT100 laser level polycarbonate plastic window

Overview

The LLT100 laser level transmitter is provided to customers who need a hygienic model with a tri-clover flange interface (product flange code H). This interface, with a diameter of 10.16 cm (4 in.), supplies a fast and easy solution to connect or disconnect the product from the process.

The materials which are exposed to the process are polycarbonate and stainless steel. Both of these materials and their surface finish are FDA approved.

The instrument housing is available in both stainless steel or painted aluminum. The window enabling the emission of the laser beam is made of polycarbonate plastic, which is a safe, recognized material for hygienic applications. As the issue of contamination is greatly reduced, non-contact measurement gives significant benefits for hygienic applications.

Utilizing lasers for performing level measurement on any solid or liquid also gives higher reliability and less maintenance since no echo mapping is required. This is particularly useful in applications with heavy vessel build-up or sticky materials or that require mixing blades.

The narrow laser pulses used are immune to changes, as they are not interacting with the surrounding environment. Measuring level is easy and reliable because laser pulses permit the measurement of very low dielectric constant materials, and also measure turbulent liquids.

CIP requirement

Maintenance

The LLT100 hygienic model is the only model which has the possibility of removing the components for cleaning.

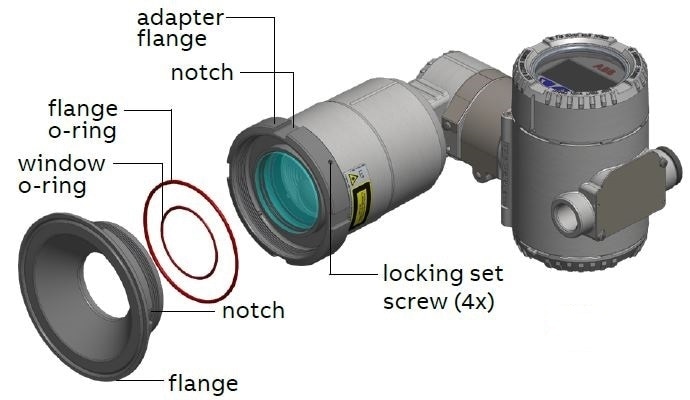

The following steps should be taken to clean the window of the hygienic model:

- Remove the four set screws and clean them

- Using two hook spanner wrenches with a diameter of 100 mm, dismantle the flange. Wrenches to be provided by the user

- Remove the window O-ring

- Clean the window, the O-rings, the flange adapter and the flange. Replace the O-rings, if they are damaged (product code G901)

*Do not dismantle the window. Opening the instrument voids the warranty

- Lay down the flange on the table and install the O-ring

- Screw the instrument on the flange by hand

- Make sure that the window O-ring remains well in place

- Tighten firmly using the hook wrenches

- Put the four set screws back

Removing the set screws

Dismantling the flange

Exploded view of inner components

Cleaning in Place

Steam cleaning in place can be carried out whilst the instrument is still connected to the process, but measurements cannot be taken during cleaning. The following limitations should be observed during CIP:

| CIP cleaning |

Tmax |

Tmax minutes |

Tamp |

| Steam |

100 °C (212 °F) |

30 |

25 °C (77 ° F) |

Summary

Laser level measurement provides a reliable and easy way of performing non-contact level measurement, particularly in industrial applications. The LLT100 hygienic model permits users in the food and beverage and pharmaceutical industry to use laser level measurement whilst meeting their sanitary requirements.

This information has been sourced, reviewed and adapted from materials provided by ABB Level Measurement Products.

For more information on this source, please visit ABB Level Measurement Products.